Basic Info.

Product Description

| Technical Parameters | |

| Principal axis | 3.5KW/4.5KW/6.0KW |

| Dimension | 2000*3000*1600mm |

| Working voltage | 380V |

| Processing area | 1300*2500mm/Can be customize |

| Work platform | Welding 4mm Steel platform |

| Table | Vacuum adsorption 5.5/7.5KW |

| XYZ stroke | 1300*2500*200mm |

| Machining precision | ±0.03mm (Less than 0.03mm) |

| Repeated position accuracy | ±0.02mm |

| Longmen structure | Thickened square steel gantry |

| Material fixation | Vacuum adsorption with motor 5.5KW(optional 7.5 KW) |

| Basement | 0.5 seamless welding quenching treatment |

| XYZ structure | X shaft slanting rack, Y shaft slanting rack, Z axis screw(+25 square rail) |

| X/Y axis | 25 square rail/ helical rack |

| Z axis | High precision TBI ball screw |

| Vacuum cleaner | 3.0 KW duster dust collector |

| Certificates | CE/SGS |

| Engraving instruction | HCP/G |

| Operating system | Shanlong system |

Product Application

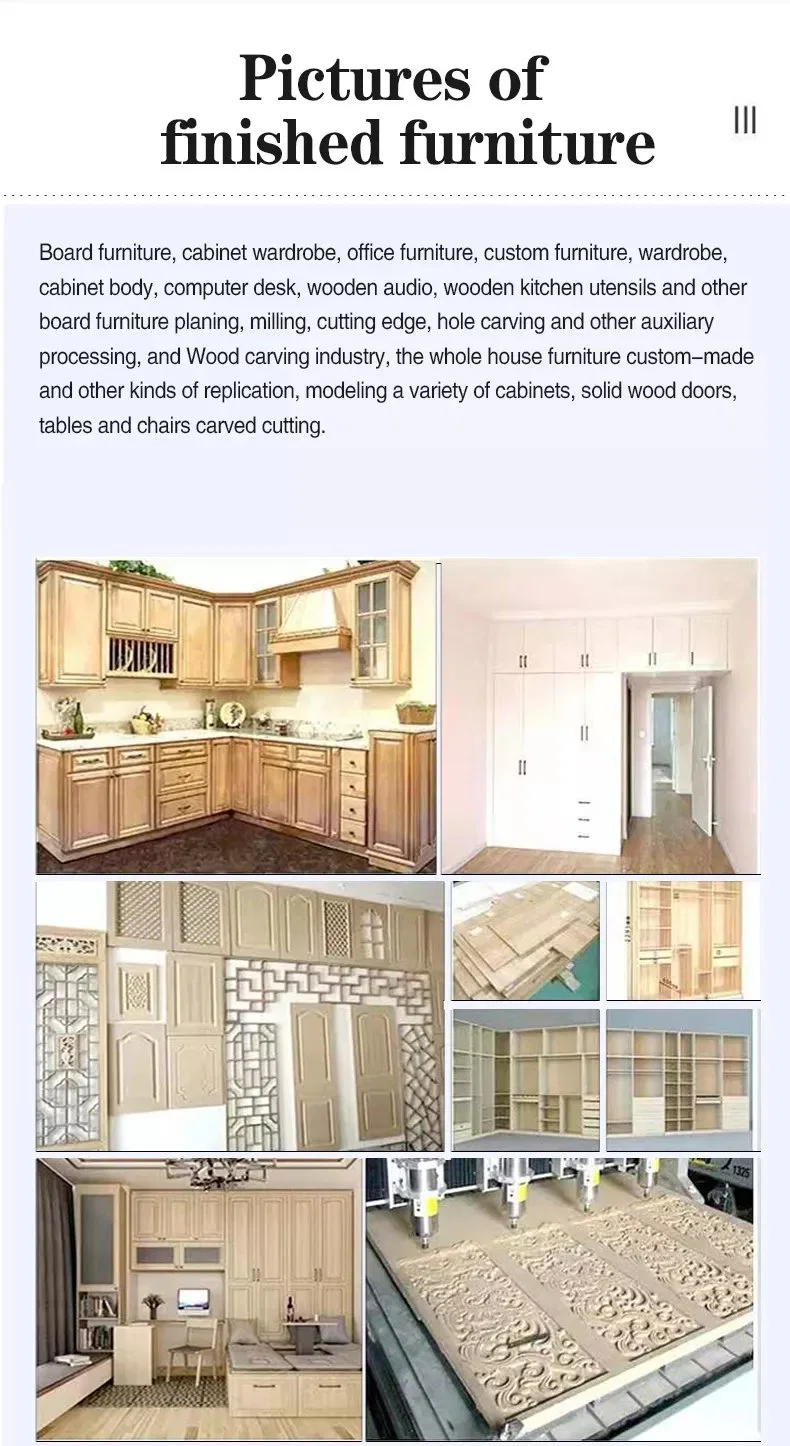

Wooden industrial products: such as sewing table, electrical cabinet panel, sports equipment and so on.

Mold industry: can carve all kinds of mold, wood mold, propeller, automobile foam mold.

Musical instrument industry: it can carve three-dimensional curved surface of musical instrument and cut it.

Such as advertising, craft gifts industry, art model industry, wood processing industry, mold industry and so on.The materials that can be processed include acrylic, double color board, PVC, ABS board, stone, imitation stone, metal, aluminum-plastic board and other materials.

Advertising industry: carving, cutting all kinds of signs, signs, marble, copper, font, all kinds of signs, trademarks and other metal materials.

Arts and crafts industry: arts and crafts, souvenirs engraved all kinds of text, graphics, iron works of art carving, dial.

Mold processing: building model, physical model, hot stamping mold, motor, high frequency mold, trace injection mold, shoe mold, badge, embossing mold, cookie, chocolate, candy mold.

Main Features

1) Heavy duty bed: the bed is welded by rectangular steel tube welder with high rigidity, with high precision and no deformation.

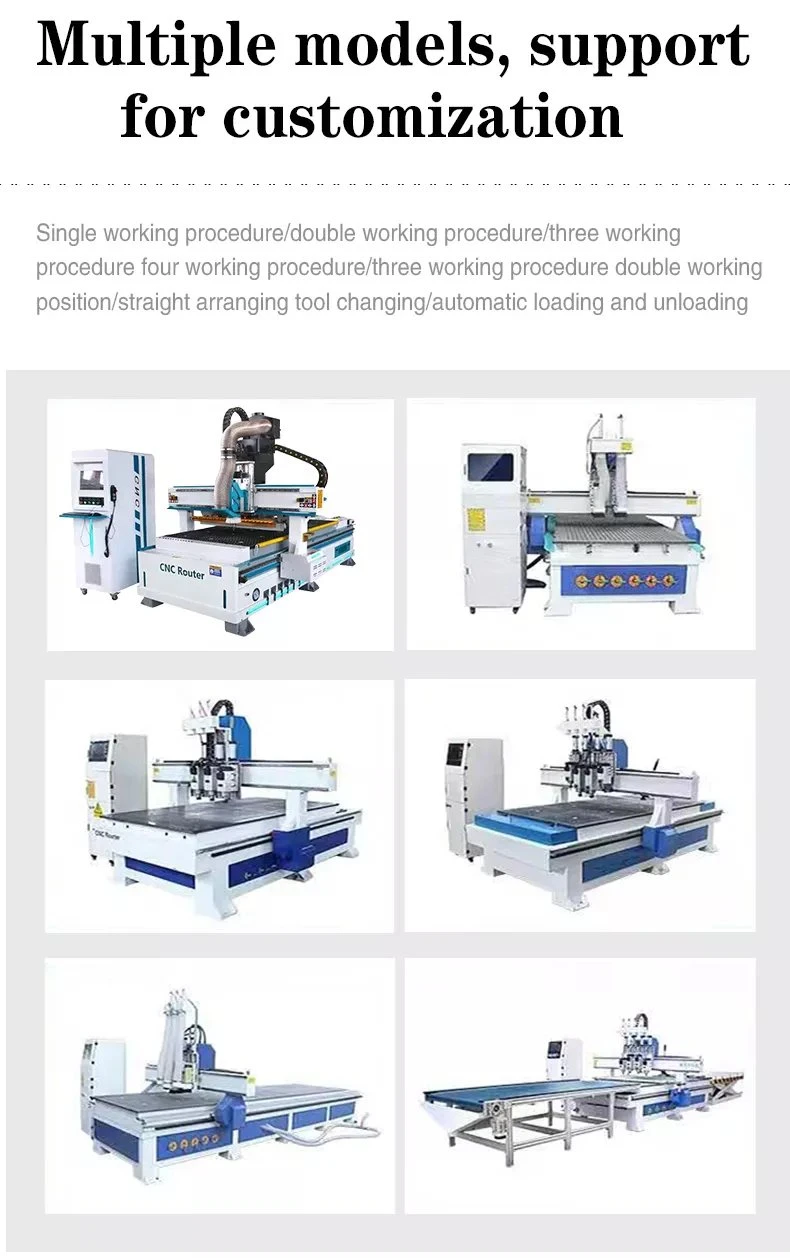

2) Three main spindles: high quality high power spindle, three spindle arbitrary switch, automatic tool change, intelligent push material, high processing efficiency.

3) Vacuum adsorption: double table vacuum adsorption, adsorption more solid plate no matter how small can also be guaranteed, good stability.

4) Imported helical teeth: high quality imported helical teeth, made of high frequency quenching, long service life.

5) Hybrid servo motor: high performance strong motor, strong performance, greatly improve the work efficiency.

6) Numerical control system: this system performance is stable, the work is simple and stable, the line is high and soft, the anti-cold, the anti-interference will not bring you resistance because of the software problem.

FAQ