Basic Info.

Model NO.

DO-1625S

Power Source

Electric

Layout

Vertical

Working Area

1600*2500mm

Method of Fixing Material

Vacuum Adsorption

Transmission

High Precision Helical Rack

Driving

Japan Panasonic Drive + Precision Reducer

Crossbeam

Aviation Aluminum Alloy with Mold Extruded

Transport Package

Wood Crate

Specification

1625

Trademark

FLYING

Origin

China

HS Code

84411000

Production Capacity

100PCS/Month

Product Description

cnc knife cutter for fiberglass carbon fiber glass fibre cloth film leather garment label carpet rubber gasket EVA EPE PET foam

Introductions: One more flexible and intelligent digital cutting machine:

DEVEUP cnc digital cutting machine is very efficient, accurate and high-quality compared to manual cutting. As labor costs become higher and higher, choosing a smarter cutting method is a smart choice.

The digital cutter is equipped with automatic nesting software, automatic feeding system and vacuum adsorption system. The vacuum adsorption system draws and fixes the roll-shaped prepreg, and then imports the designed image, such as AI, CorelDraw, CAD, etc. into the machine cutting operating system. The digital cutter automatically cuts on the composite based on the designed graphic.

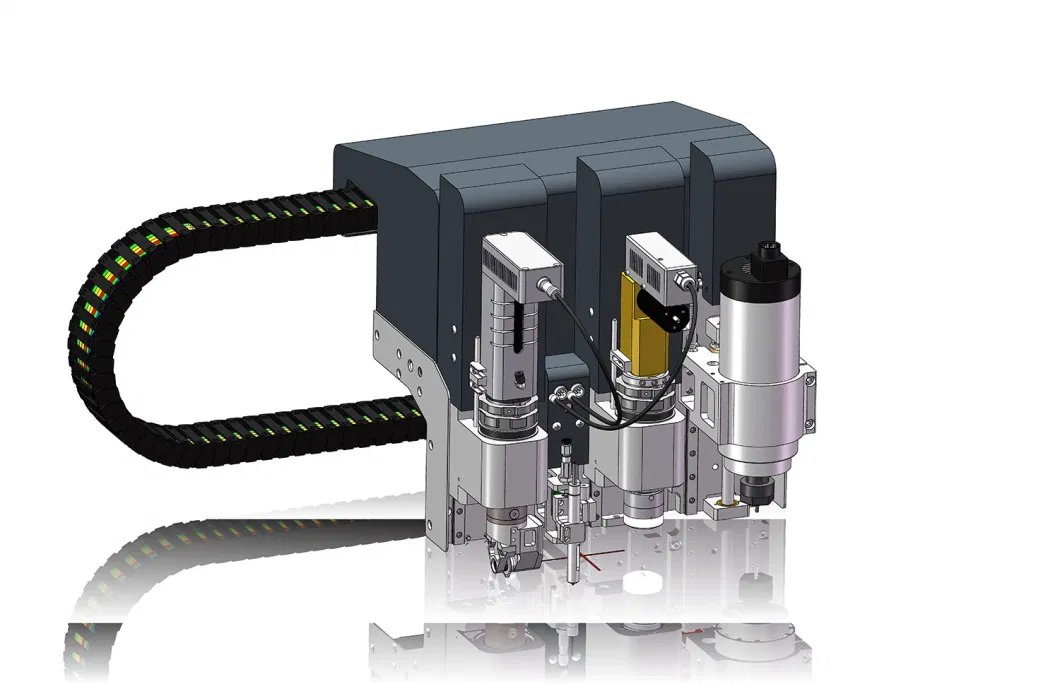

A variety of cutter heads to meet different materials cutting needs:

Composite materials cutting machines are mainly for composite cutting. For example, carbon fiber, glass fiber, soft glass, prepreg, carbon felt, rubber, graphite sheet, silica gel, sound insulation, honeycomb profiles, etc. With a variety of tools and pens to meet the cutting needs of different materials, and provide a variety of personalized cutting services.

Processing advantages

Carbon fiber prepreg cutting machine can replace manual cutting, help you save more labor, die and material production costs, and solve your difficult job recruitment and high labor costs!

3 problems of artificially cutting carbon fiber fabric:

1. Some industries have high requirements for cutting precision, manual cutting cannot meet the cutting requirements;

2. The efficiency of manual cutting complex patterns is low, which cannot meet the needs of mass production;

3. The cost of manual cutting is high. If efficiency and precision are required, the number of workers can only be increased, and the cost of workers will be greatly increased.

Advantages of carbon fiber prepreg fabric cutting machine:

1. The carbon fiber prepreg cloth cutting machine uses an automatic feeding work platform and is equipped with a super discharge system, which saves time for manual typesetting, improves work efficiency, and saves 10% of materials;

2. The traditional manual cutting efficiency and precision can no longer meet the needs of the market. The cutting accuracy and efficiency of the carbon fiber cloth automatic cutting machine can meet the needs of different industries;

3.The carbon fiber prepreg cloth cutting machine adopts the advanced vibration knife cutting machine technology, the edge of the cut fabric will not appear yellow and scorched, there is no odor at the processing site, and the cutting edge is smooth;

4. High degree of intelligence, combining automatic feeding, automatic nesting and automatic cutting system, which reduces production costs and improves production efficiency.

Tips:

Composite materials are generally composed of two or more different substances in different ways. It can exert the advantages of various materials, overcome the defects of a single material, and expand the scope of the application of materials. Due to the characteristics of light weight, high strength, convenient processing, excellent processing, excellent elasticity, good chemical corrosion and good weather resistance, it is widely used in the fields of aerospace, automobiles, electronics, construction, fitness equipment. However, artificial cutting difficulties and poor quality, which cannot meet the diverse and high -precision cutting needs of compound materials at all.

Our automatic fabric cutting machine adopts high -frequency oscillating knife cutting technology, which can meet various composite materials such as glass fiber, carbon fiber, boron fiber, araceae fiber, silicon carbide fiber, and asbestos fiber. The cutting of composite materials has the following advantages:

1. Compared with the laser machine, the processing speed is faster, the cutting section is smooth, and the scorched material will not be burned. There is no smoke and dust during the entire processing process, which is more environmentally friendly;

2. Compared with traditional mold stamping, there is no need to make molds, which is more flexible, meets different shapes and batches of order production, and realizes rapid delivery;

3. High -end quality manufacturing, the dual -drive Mitsubishi servo motor is used, and the entire department Schneider Electric is used to ensure the last and stable work of the machine;

The automatic tracking system can meet the rapid and continuous processing of the coils. It only needs one person to operate, and its efficiency is equivalent to 4-5 personal workers.

Specifications:

| Parameters/Model | DO1625F DO1330F DO1650F (multiple sizes optional, can be customized) |

| Working Size | 1600*2500mm 1300*3000mm 1600*5000mm |

| Safety device | Physical anti-collision mechanism + infrared induction anti-collision to ensure production safety |

| Cutting thickness | ≤50mm (Other thickness can be customized according to the material) |

| Cutting speed | ≤1800mm/s(The actual speed depends on the material and cutting graphics) |

| Applicable materials | PU, leather, Cloth, PVC, Foam, sound-absorbing cotton, photo paper, KT board, car stickers, rubber, sponge, cloth, carton, film, fiberglass, fabric, carbon fiber, and other composite flexible materials |

| Cutting precision | ± 0.1mm |

| Repeat accuracy | <= 0.05mm |

| Cutting circular diameter | >=3mm Diameter |

| Positioning way | Laser positioning also optional CCD camera positioning |

| Safety device | Infrared induction, safe and reliable |

| Material fixed way | Vacuum adsorption |

| Transport interface | Ethernet front-end ports |

| Compatible software format | AI software, AutoCAD, CorelDRAW, and all of the box type design software can output directly, without conversion, and with automatic optimization |

| Command system | AI, PLT, DXF, JPEG, CDR and ETC |

| Operation panel | Multilingual LCD touch panel |

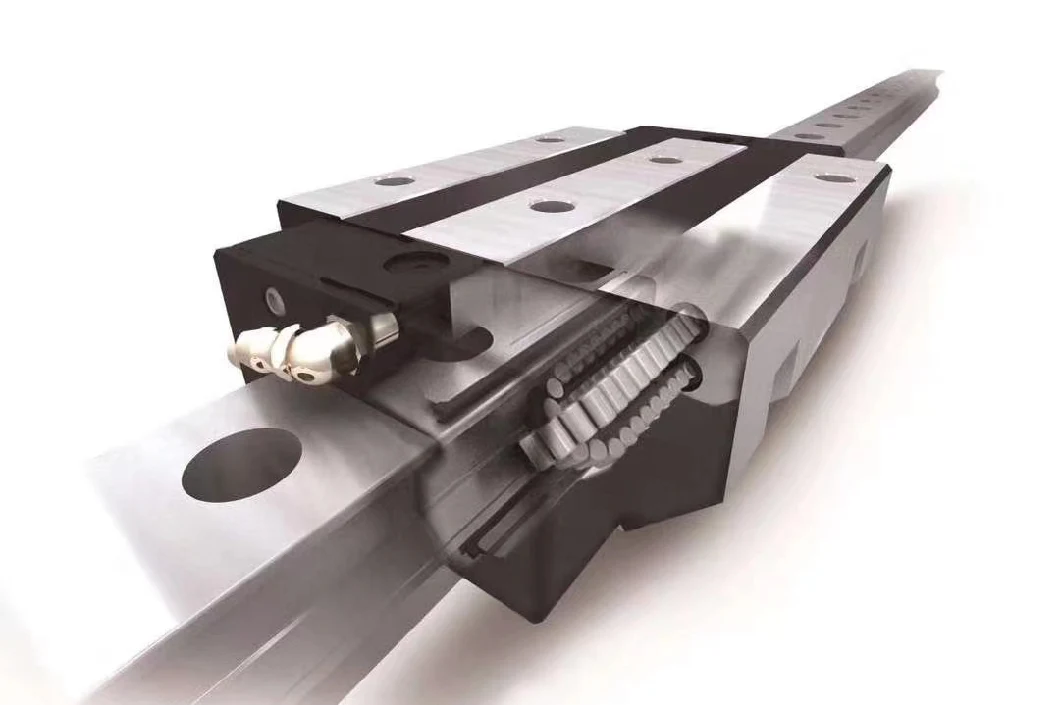

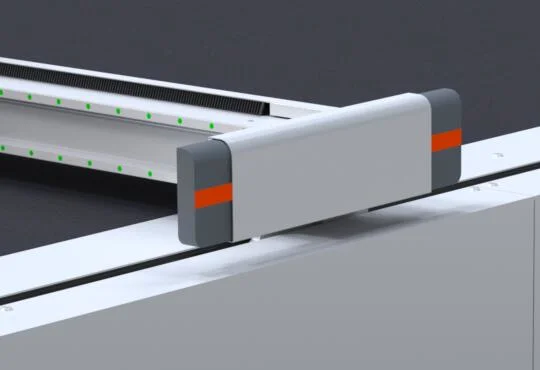

| Transmission system | High precision linear guide, meshing transmission gear and rack structure, Japanese Panasonic high performance servo drive motors + precision reducer |

| Power supply voltage | Ac 220 v to 380 v + 10%, 50 hz. |

| Pump power | 7.5kw/9kw/11kw |

| Work environment | Temperature: - 10 ºC to 40 ºC, humidity: 20% ~ 80% RH |

Machine Details:

Colorful & touch control operation panel, with more intuitive operation interface, which can directly input processing data, set processing speed and knife depth, support screen automatic protection, and protect processing data,feature-rich and user-friendly operation

A variety of tool combinations, equipped with intelligent prop interchange system, can cut different materials to achieve different tasks, and multiple tool heads can work individually or in concert. Powerful function, fast running speed, high processing accuracy, truly multi-purpose machine.

We insist on using 6mm thick, 60mm diameter steel pipes, and adding load-bearing brackets in the X and Y axis directions every 80-100mm span. We use 60mm thick cast iron in the frame and guide rail mounting position and use CNC gantry machining center for planing and milling. Our bed has the characteristics of heavy weight, good load-bearing capacity and high hardness, which ensures the accuracy and stability of the oscillating knife cutting machine at high speed. We guarantee that the machine will not be deformed in 10 years.

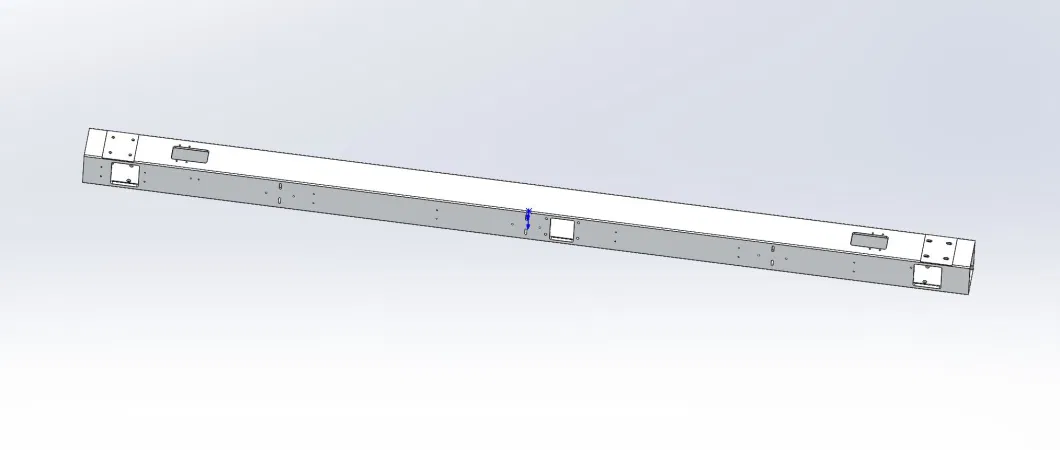

The beam adopts the extrusion process of aviation aluminum alloy die, which ensures the stability and high precision of machine operation at high speed, especially suitable for some industries that require high precision, such as sealing gaskets

Imported famous brand helical gear rack, quenching and hardening treatment. High precision, strong load-bearing capacity, smooth running at high speed and less noise.

Taiwan PMI 20mm high precision linear guide, high positioning accuracy, high repeatability. Low friction resistance, high rigidity four-way load design, high speed and long time operation to maintain high precision

Safety protection device. Highly sensitive collision avoidance system and red light brake system. When the machine is cutting at high speed, it can effectively protect safety of the operator.

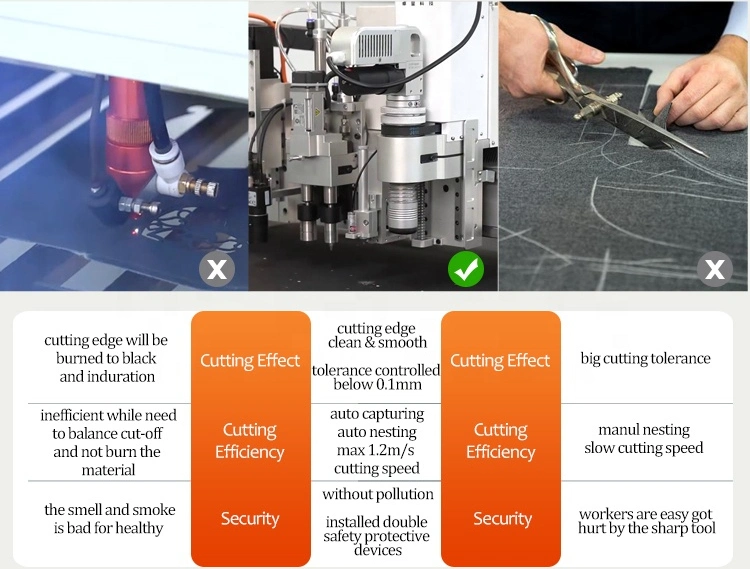

Advantages compared with laser cutter and manual:

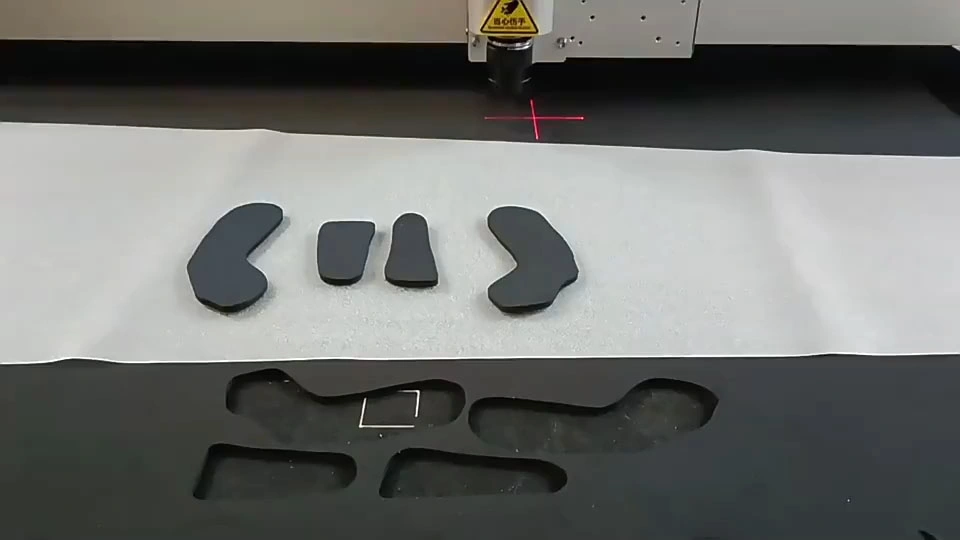

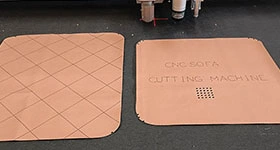

Cutting Samples:

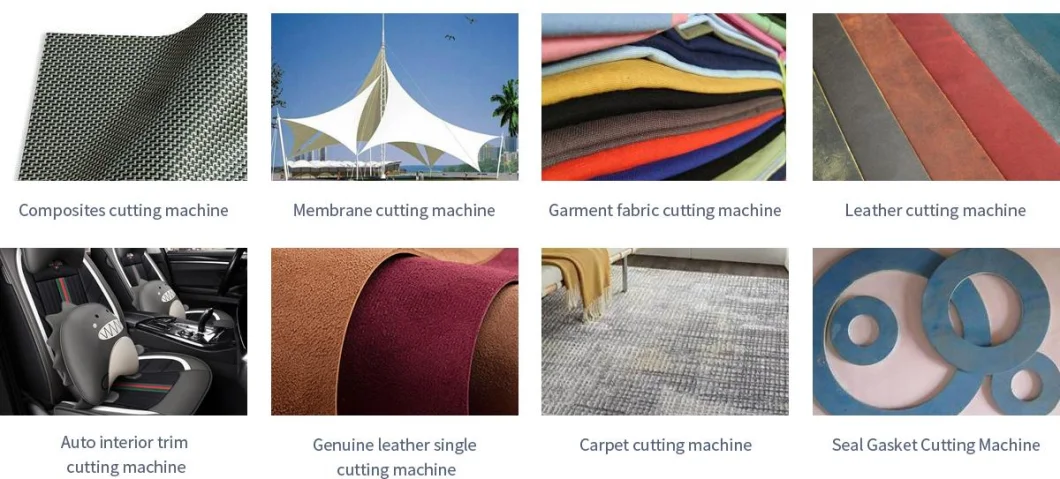

More Applications:

Why Choose Us?

We provide customers with automated production equipment that replaces skilled workers and reduces labor costs.

We equip our machines with automated typesetting software that provides customers with an optimal layout plan, maximizes material utilization and avoids wasted material.

Our equipment is easy to operate. The digitalized processing transforms "old-fashioned" repetitive work (typesetting, changing size, etc.) into one operation, making it more "user-friendly," reducing employee turnover and its negative effects on production.Digital production enables a seamless cooperation between machine and man that has never before been possible.

The efficiency of our machines is unparalleled and the supply cycle is shortened, which makes our customers become the leaders once again in a highly competitive industry.