- Overview

- Product Parameters

- Our Advantages

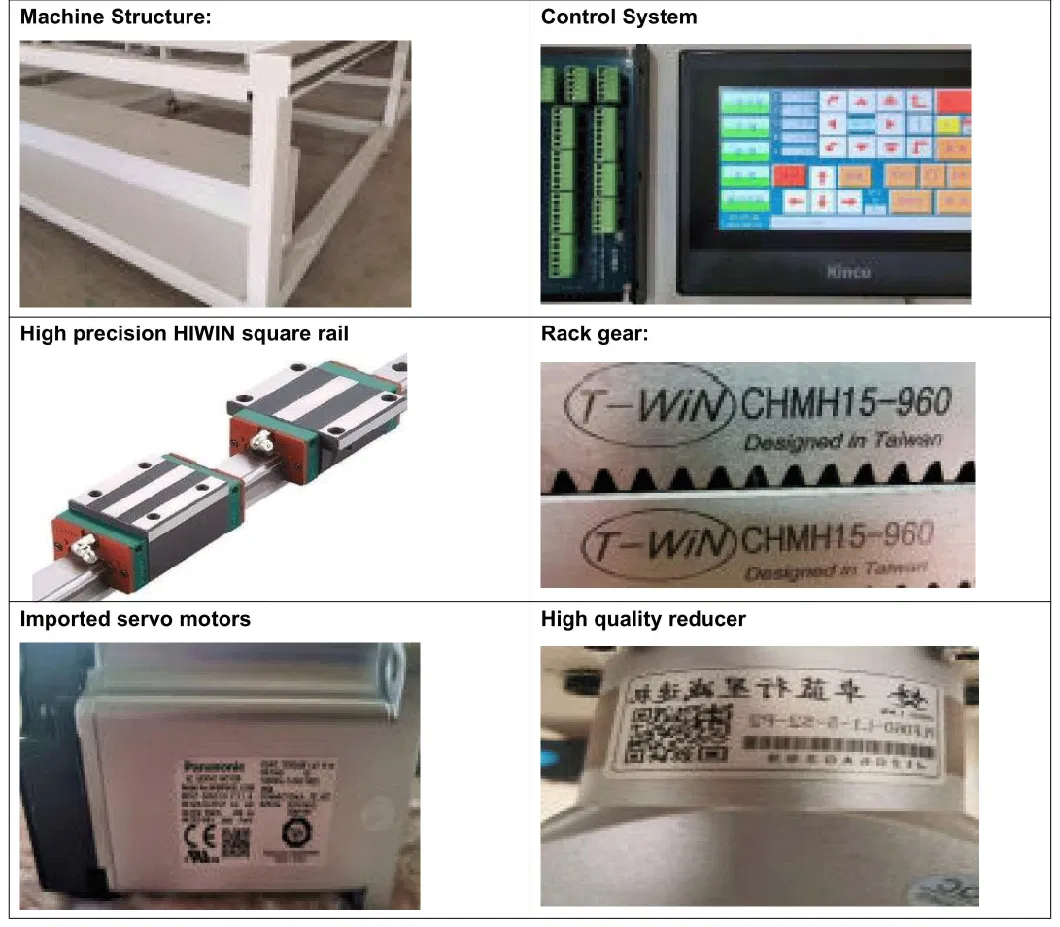

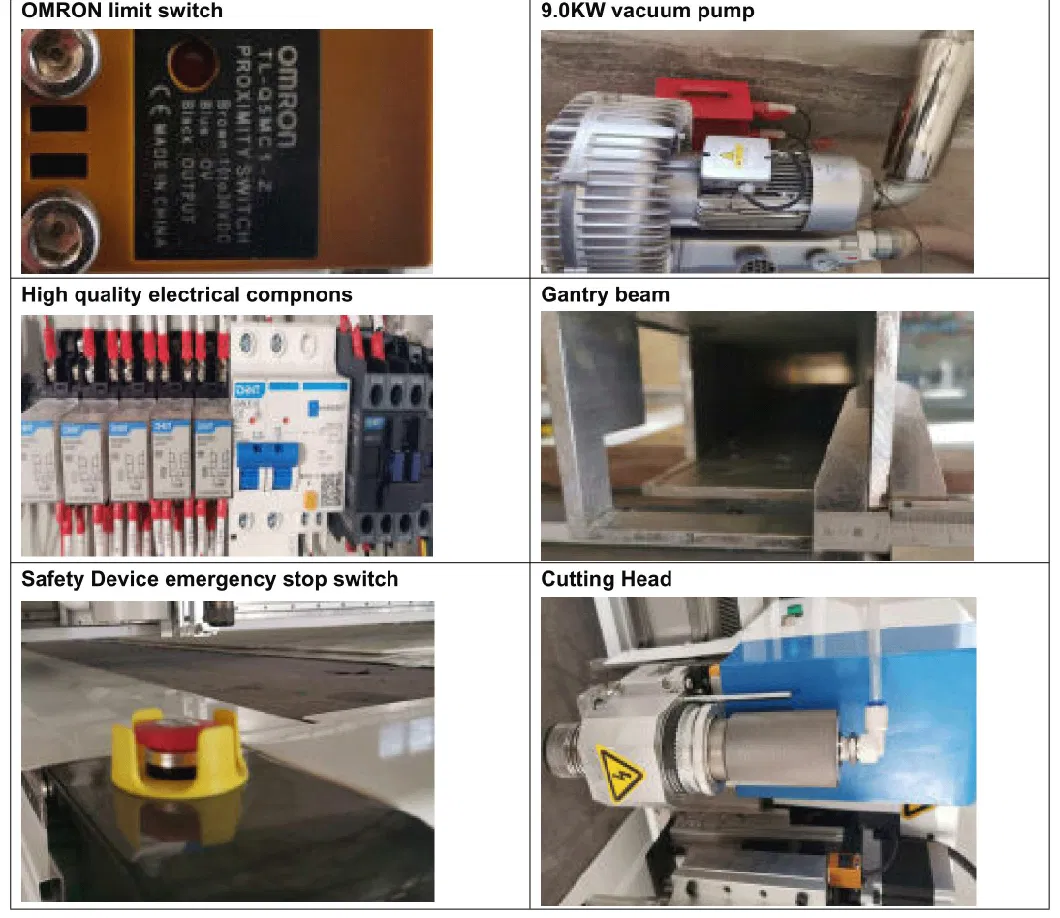

- Detailed Photos

- Working Samples

- Packaging & Shipping

- Contact US

Basic Info.

Model NO.

SSR-1625V

Cutting Speed

200-800mm/S(According to Different Cutting Materia

Cutting Thickness

≤15mm(According to Different Cutting Materials)

Control System

Zhongrui

Vacuum Pump

9.0kw Air Cooling Pump(Higher Optional)

Limit Switch

Imported Omron

Safety Device

Infrared Sensor Anti-Collision System

Transport Package

Wooden Package

Specification

1600mm*2500mm

Trademark

SSR CNC

Origin

China

Production Capacity

100 Sets/Month

Product Description

CNC Router Oscillating Cutting Machine Foam Cutting Machine Vibrating Knife Cutter for Sponge SSR-1625V

When cutting thick foam, EVA, sponge, we suggest use Pneumatic knife

| Model | SSR-1625 (auto feeding function is optional) |

| Working area | 1600mm×2500mm |

| Machine size (mm) | 3050mm*2200mm*1250mm |

| Fixed mode | Auto feeding type table |

| Multifunctional Cutting head | Swiss imported knife: with vibration full cutting, vibration half cutting and cursor location function. |

| Translation velocity | 800-1200mm/s |

| Cutting speed | 200-800mm/s(according to different cutting materials) |

| Cutting thickness | ≤15mm(according to different cutting materials) |

| Cutting materials | Leather, all kinds of clothing flexible material, Sponge composite leather, , soft glass, Silicon, rubber |

| Repeated accuracy | ≤0.1mm |

| Capacity | 1.0GB |

| Control System | ZHONGRUI |

| Guide | High precision HIWIN brand |

| Transmission | High precision helical rack gear |

| Drivers and motors | Imported digital servo motors Japanese YASKAWA |

| Vacuum Pump | 9.0KW air cooling pump |

| Limit Switch | Imported OMRON |

| Safety Device | Infrared sensor Anti-collision system |

| Gantry Beam | Industrial Aluminum 6061 |

| Working Table | Vacuum aluminum bellows, Independent worktable |

| Auto Lubrication System | With |

| Instruction system | HP-GL compatible format |

| Machine Voltage | 220V±10% |

| Other Standard Accessories | 10 pieces cutting knifes, cable line, data line, editing software, tool case, wrenches |

Advantages of Auto Vibrating Knife Cutting Machine:

| 1 | Non-Laser | no scorching, no discoloration, no peculiar smell |

| 2 | High-Tech | Ultra-high frequency vibration knife technology realizes perfect cutting. |

| 3 | High Speed | It only takes 5 minutes to cut a set of 35-segment car seat covers, 20 minutes to cut a set of 150-seat car seat covers, and 6 minutes to cut a set of car seat covers. It takes only 80 seconds to cut a set of car mats. |

| 4 | High efficiency | It can complete the die-cutting, creasing and forming of flexible materials such as leather, paper and plastic without die cutters and die-cutting machines, which can save a lot of manpower, die cutters and die-cutting machine costs. |

| Different knife cutter tools for different materials cuttings You can tell us the materials you mainly cut, we will recommend suitable tools for you: |

Digital knife cutting machine suit for leather, fabric, textile, cardboard, plastic box, fiber glass,corrugated cardboard, sticker, film, foam board,rubber, cloth, gasket material, garment cloth, footwear material, bags materials, non-woven fabrics,seat cover, carpets/rugs, sponge, PU, EVA, XPE, PVC, PP, PE, PTFE, ETFE and composites.

1. We use international standard exporting plywood package, which is fumigation-free

2. We offer item FOB, CIF, CFR, DDU, EXW by sea:

- FOB: Customer need to find shipping forwarder by himself, take machine from China sea ports

- CIF: We will find shipping find shipping forwarder for customer, arrange sea delivery for customer from China sea port to customer's country sea port, buy sea insurance for customer

- CFR: Under CFR item, customer need to buy sea insrance by himself, other is sampe as CIF item

- DDU: Under DDU item, we arrange machine delivery from our factory address to customer receiving address

- EXW: Customer need to arrange take machine from our factory and arrange all from China sea port to customer's country sea port

3. We can also offer delivery by air for small package machine