Basic Info.

Model NO.

FV1625

Power Source

Electric

Layout

Vertical

Working Area

1600*2500mm

Method of Fixing Material

Vacuum Suction

Transmission

Rack

Driving

Servo

Transport Package

Wood Crate

Specification

1625

Trademark

FLYING

Origin

China

HS Code

84411000

Production Capacity

100PCS/Month

Product Description

Printed carpet Velvet Blended carpet floor mat rug curtain fleece Faux Fur coat cloth leather digital cutting machine

Introductions:

This digital oscillating cutting machine is equipped with automatic feeding system, image recognition system and projection positioning system, which realizes automatic extraction of image outline, automatic positioning and cutting, and solves the difficult problem of printing fabric cutting and irregular material cutting.

Quickly cut a variety of printed fabrics, striped textiles, carpet, floor mat, Diatomite Floor Mats,and genuine leather with oscillating knives or drive-wheel knives. This knife digital cutting machine with CCD camera has a maximum cutting speed of 7200mm/min, a maximum cutting thickness of 50mm, and a repeatability position precision of 0.02mm.

Specifications:

| Model | FV1630 | |||

| Working area | 1600mmX3000mm | |||

| Multi-function tool | Vibrating knife, semi-cutting cut, indentation, drawing mark, cursor positioning, camera positioning edge cutting, high power active round knife | |||

| Safety devices | Safety devices use infrared sensing, safe and reliable | |||

| Applicable materials | PVC, leather, sponge composite skin, fabric , XPE material, wire ring, leather, soft glass, silicone, rubber material, etc composite soft material | |||

| Material fixing method | Vacuum partition adsorption | |||

| Cutting speed | 0-1500mm/s ( According to material) | |||

| Software system | Intelligent identification and nesting system, fast cutting system | |||

| Advantage configuration | 01. X-axis double Mitsubishi servo motor + precision reducer drive; 02. The beam adopts the extrusion process of aviation aluminum alloy die; 03. All electrical accessories use the French Schneider brand. | |||

| Rated power | 11KW | |||

| Rated voltage | 380V±10%/220V±10% Optional | |||

| Support file format | AI, PLT, DXF, Retc | |||

So, how can our camera positioning cutting machine help customers to better improve product cutting quality, reduce production cost and improve market competitiveness?

1. Simplify processing procedures and reduce production costs:

It is equipped with an automatic identification system, which can quickly identify the contour of the cutting pattern or material, and can automatically nest according to the contour of the material, realizing automatic processing;

2. Improve cutting efficiency and precision. Reduced labor costs:

Helping customers achieve fast and accurate edge cutting. The cutting efficiency is 3 to 5 times that of manual work, and some materials will reach more than 5 times. One machine can replace 3~5 workers, and the operation is simple. Solve the problem of difficult recruitment and high labor costs

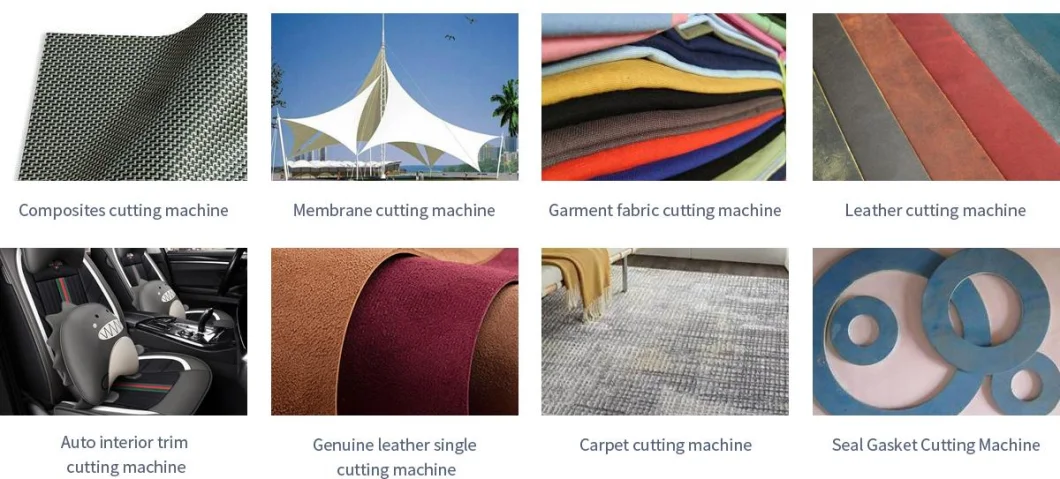

More Applications:

Cutting Samples:

Cutting Tools: