Basic Info.

Model NO.

KJCT-1625

Power Source

Electric

Layout

Horizontal

Cutting Speed

1000mm/S

Cutting Thickness

50mm

Voltage

110/220/380V

Safety Device

Infrared Radiation/Anti-Collision/Emergency Stop

Transport Package

Wooden Box

Specification

1600*2500mm

Trademark

kangjia

Origin

Jinan China

HS Code

8461500090

Production Capacity

100 Sets / Month

Product Description

Production

Voltage:110-380v

Power:9-11kw

Cutting materials:flexible materials

Fixed method:vacuum absorb

Moter type:servo motor

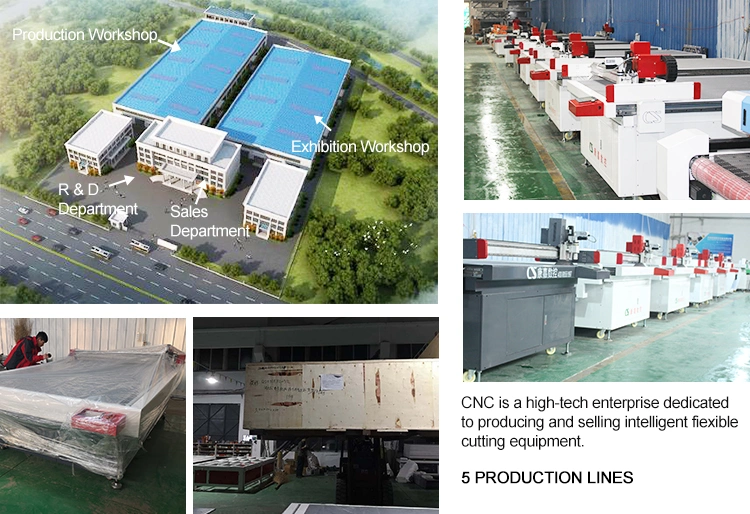

About us

Jinan Kangjia CNC Equipment Co., Ltd has focused on CNC equipment production for over 5 years. It is a comprehensive service company specializing in the production, sales and technical service of oscillating knife cutting machine. It covers multiple fields and industries, such as automotive decoration, toys, garment, leather product, furniture etc. Its R&D level and production capacity has always been in the leading position in the same industry. Our factory is located in Jinan city of China. It covers 10000 square meters, with 150 staffs in total. The production capacity is about 100 unit / month.

Certifiction

Exhibition

Packing and delivery

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

Why choose us

1. Saving labour and material cost

2. Saving time

3. Everyone can operate and cut without lots of skills

4. Boost production capacity

5. Consistent accuracy even with complicated patterns

6. Reduces your lead times of pattern cutting from your clients

7. Wide range of clothes/garment/apparel material application

8. Running in a high automaton

9. Special design: less moving structure guarantee low down time and easy in installation and maintain

10. Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

11.Good experienced engineers

12. CNC control

13. Knife cutting method: oscillating Blade with multifunctional tool heads

14. Easy conversion

15. With more and more agents / partner joining us, after sales team can be in your country by your side.