Basic Info.

Product Description

Factory wholesale 3d wood carving machines , woodworking cnc cutter for wooden chair legs

Specifications

Model | JCW1325R--8H |

Working size | 1200mm ( L) x 300mm (W) x 10 rotaries |

Spindle power | 10*3.5KW Air Cooled (option: Water Cooled) |

Spindle rotating | 0-18000rpm |

Max moving speed | 20m/min |

Reposition precision | 0.05mm |

Control system | 5 Axis Syntec (option: Ncstudio) |

Motor | Servo system |

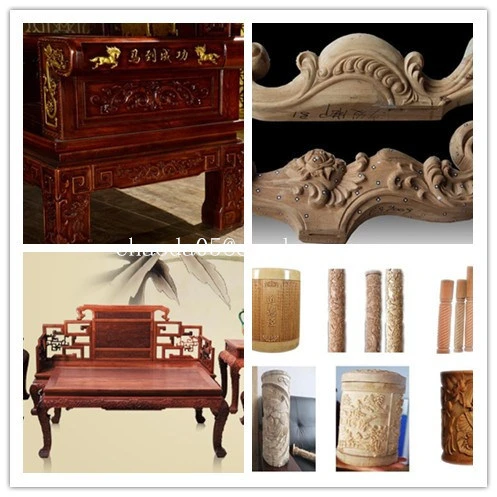

Application

All kinds of wood, hardwood, solidwood, plywood, foam, EPS, polystyrene, polyurethane, styrofoam, polyfoam, composite board, PVC, plastic, acrylic, Organic glass, and other materials.

1) Decoration industry

2) Advertising industry

3) Mould industry

4) Construction industry

5) Craft industry

6) Furniture industry

7) Sculpture, statue, figure industry

8) Model industry

More Samples

Main Features

2) Each spindle has two heads with two tools, which is equivalent to Auto Tool Changer

3) Multi spindles can work at the same time,also can work alone, many times increasing inefficiency. can also

control the machine heads independently, can use only one head to process and make increasing the working

area.

4) This machine is very suitable for furniture bulk production such as desk legs/stair handrails and other column /

cylinder products,it also can easily engrave 360 degree human body, Buddhist statue, sculpture and other art

works

5) Easy-to-operate Taiwan SYNTEC control system

6) Powerful PowerMill software with post processor

7) Except X, Y, Z and Rotary Axis, the 5th axis is the spindle can swing front and back, which can do more complex work.

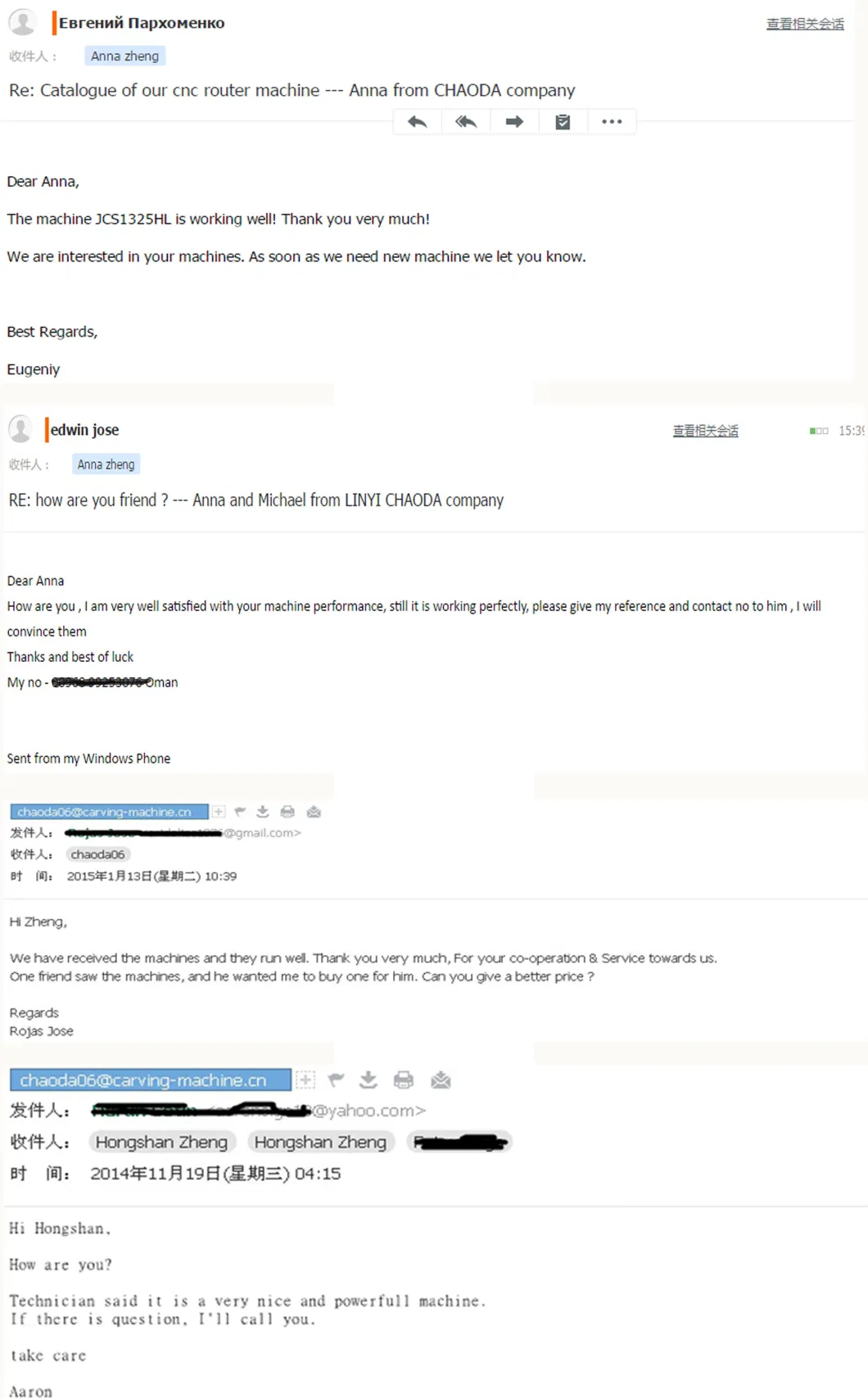

Company Information

FAQ

Linyi city, Shandong province, China.

From Shanghai to Linyi by airplane: about 1 hour

From Beijing to Linyi by airplane: about 1 hour

From Guangzhou to Linyi by airplane: about 2 hours

2) Payment term:

50% T/T deposit payments in advance, the balance should be paid before shipment

3) Delivery time:

1 month

4) Free training in our plant:

Including how to make program (tool path) by PowerMill software, how to install and operate

the machine, normally 2~3 days