Basic Info.

Model NO.

2513

Computerized

Computerized

Automatic Grade

Automatic

Application

Paper Packaging Materials, Stickers Products

Cutting Speed

up to 1200mm/S

Max. Cutting Size

2500mmx1600mm

Cutting Thickness

50mm or Less

Max Take off The Paper(mm

360X360

Feeding Pile Height(mm)

1150

Package Dimension(mm)

3650mmx2620mmx1280mm

Cutting Material

Corrugated Paperboard, Grey Board, Kt Board, PVC

Transport Package

Standard Exporting Wooden Box

Specification

6000*4200*2400mm

Trademark

EcooGraphix

Origin

China

Production Capacity

5000 Sets/Year

Product Description

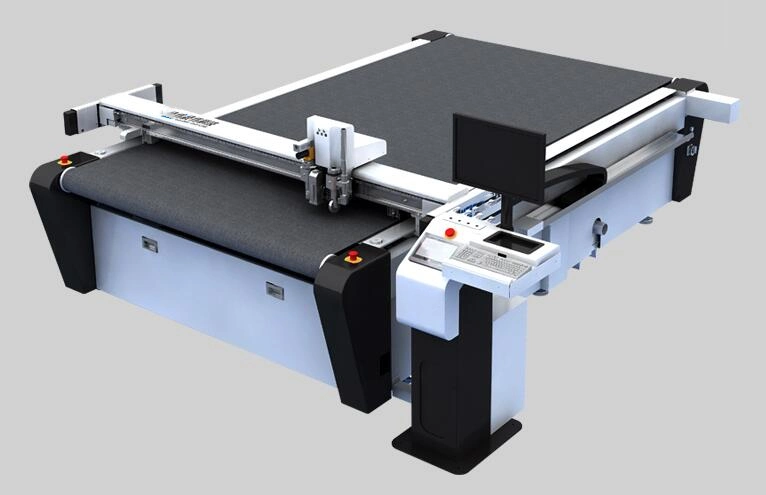

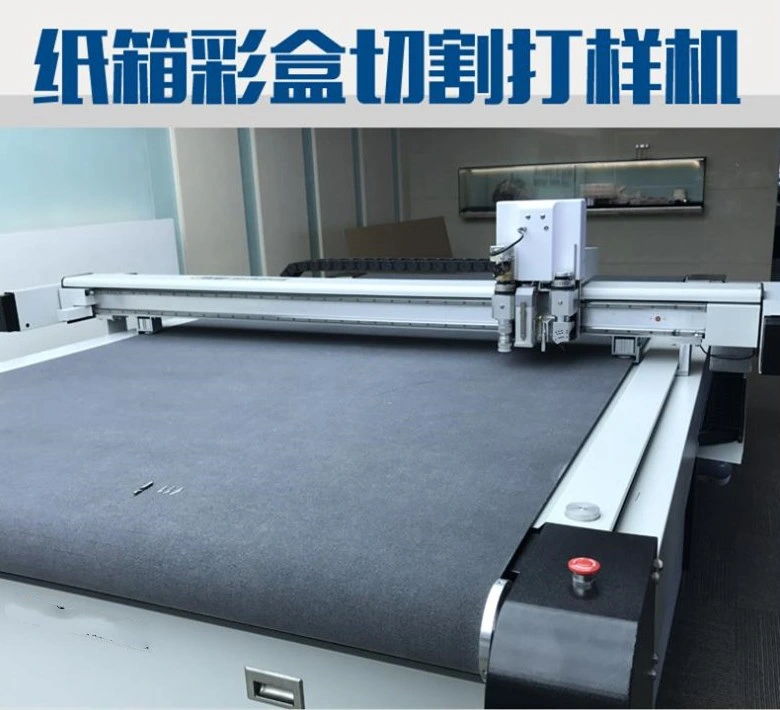

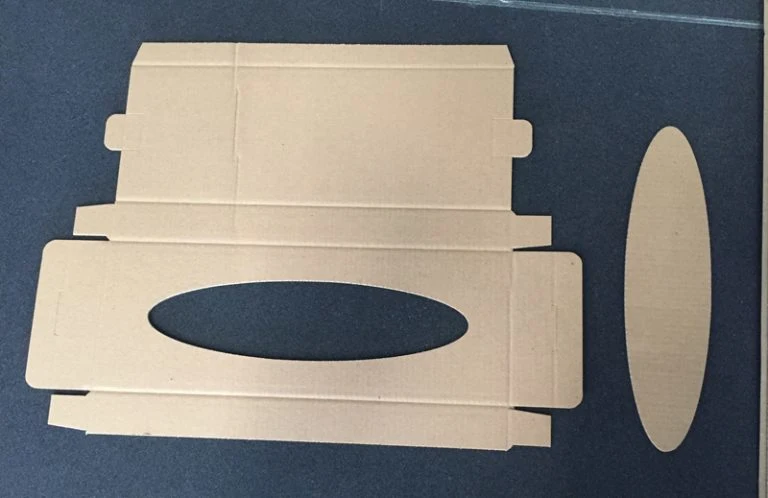

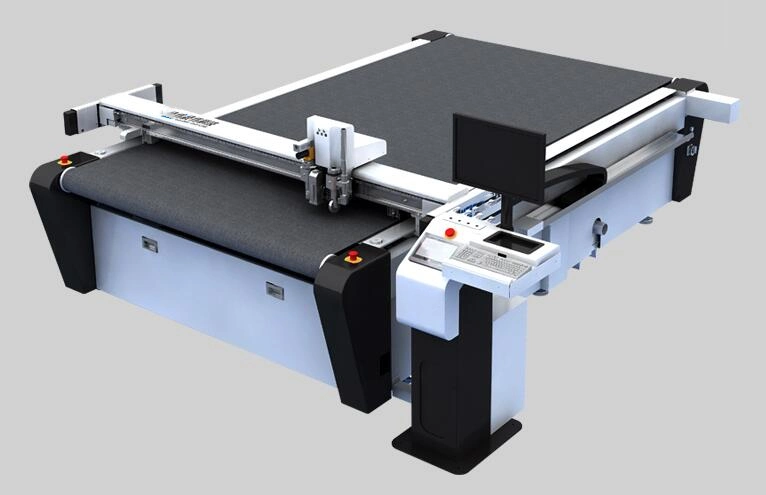

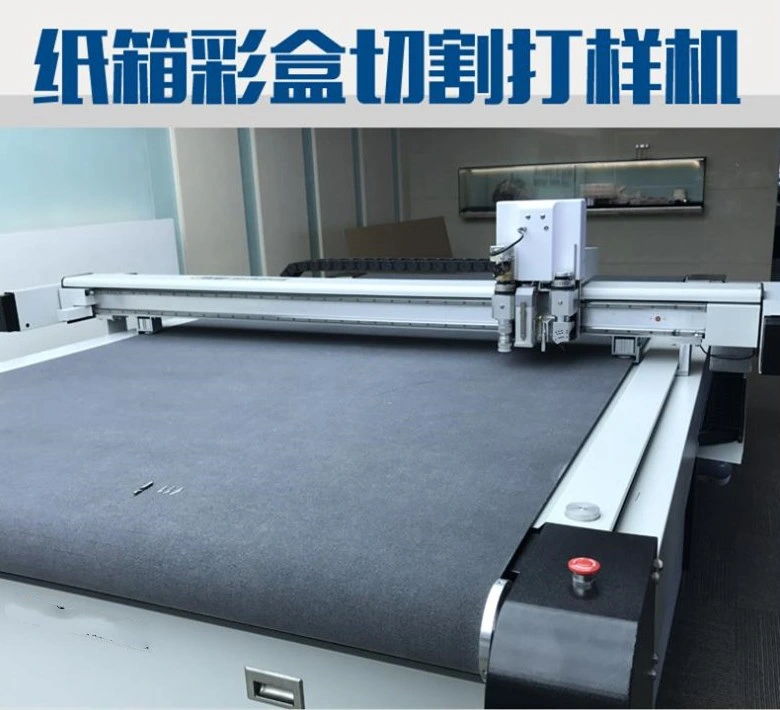

Flexible Digital Die Cutter for Cardboard Carton Paper Box

Digital cutting machine, digital cutter, no-die cutting machine, flexible cutting machine, flatbed cutting machine,Digital Cutting table

Product Description

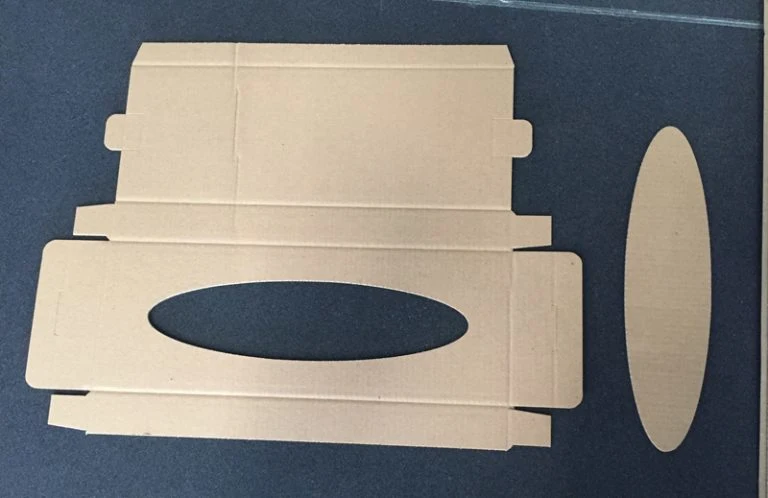

As more and more cardboard or corrugated board printing jobs become smaller volume and tailor made. Digital cutting table can be well fit for cutting boxes after digital printing (as I introduecd last time digital corrugated printers). Digital cutting table can be used for small volume production as well as sampling. Almost every cardboard or corrugated printers could make good use of digital printers and digital cutting tables for small volume jobs.

2. Core technology

3. STANDARD TOOLS CONFIGURATION

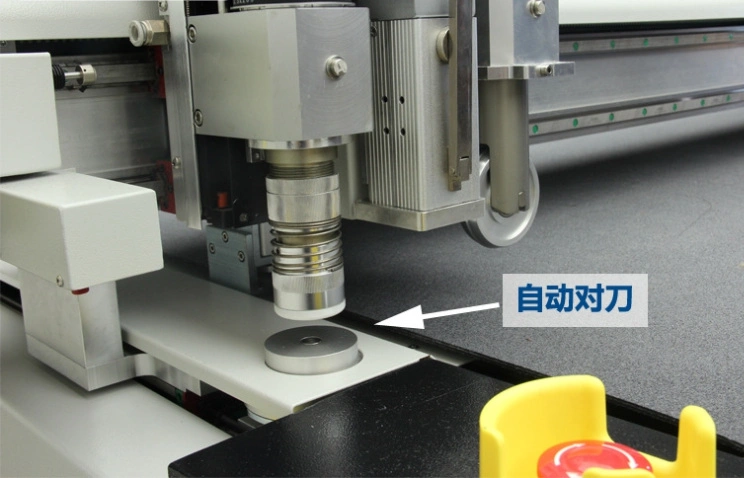

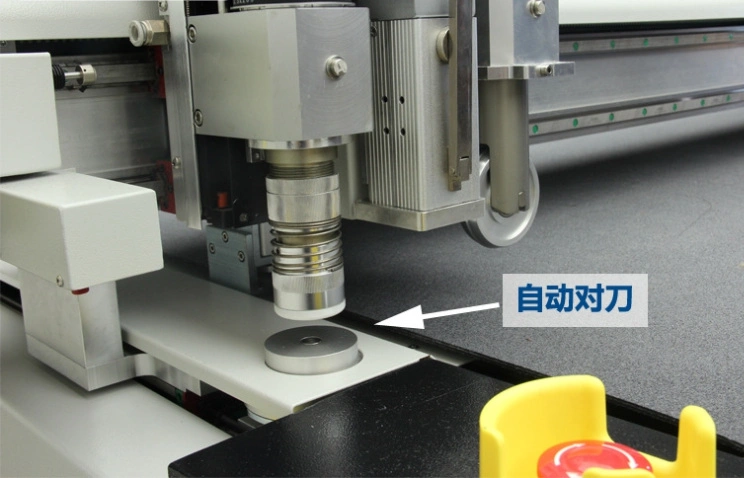

Two multi-tool module / Plotting Pen / Laser Locating Pointers (For manual alignment) / Proximity Sensor and Emergency Stop / Vacuum Table with individul area vacuum pump / Auto-Cut Deph Setting Device

Touch Screen Controls / Sound Absorber / Air Compressor / Software with dongle

4. Cutting material

All kinds of corrugated paperboard, grey board, KT board, PVC expansion sheet, honey comb board, car sticker, light slide, PP gum, flex banner, flag fabric, EPE foams, EVA, PVC plate, acrylic, thick foam, etc

5.About our factory

EcooGraphix TD790 is produced by the leading manufacture in China ,which has a long history more than 90years. It is the first factory to produce and supply the Die Cutting ,Foil Stamping and Automatic Gluing machines .There are thousands of Die Cutting Machines installed worldwide. And two units EcooGraphix TDS790 were installed in Hungary in 2017.

6.Quality Control

Professional control department which is responsible for all the machines.

Full checking list including mechanical and electrical detection on the machine.

Strict standard for registration and over 24 hours non-stop running on each machine.

Follow the policy of 'One person responsible for one machine' ,'Claim responsibility if machine has assemble problem'.

7.Service

All of our technicians have over 10-20 years experience.

Rich experience in installation, repairing and maintenance overseas.

After-sales staff Whatsapp/Wechat on line 24/7.

Guarantee to provide after-sales service for any machine for whole using life.

RFQ

Digital cutting machine, digital cutter, no-die cutting machine, flexible cutting machine, flatbed cutting machine,Digital Cutting table

Product Description

As more and more cardboard or corrugated board printing jobs become smaller volume and tailor made. Digital cutting table can be well fit for cutting boxes after digital printing (as I introduecd last time digital corrugated printers). Digital cutting table can be used for small volume production as well as sampling. Almost every cardboard or corrugated printers could make good use of digital printers and digital cutting tables for small volume jobs.

| Model | CB03II-2513-RM | CB03II-2513-RM |

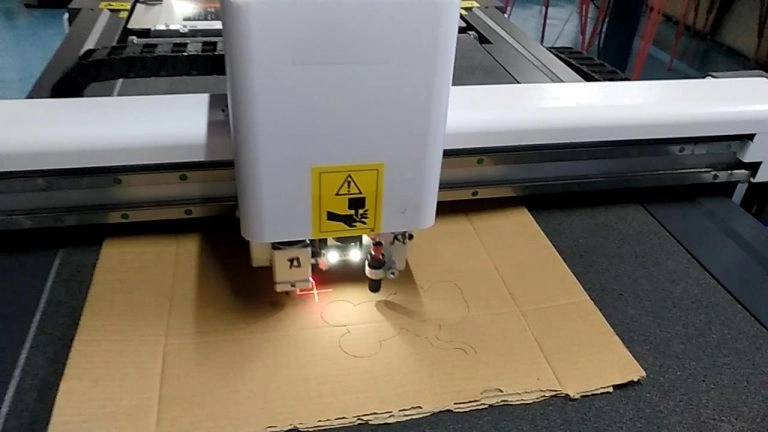

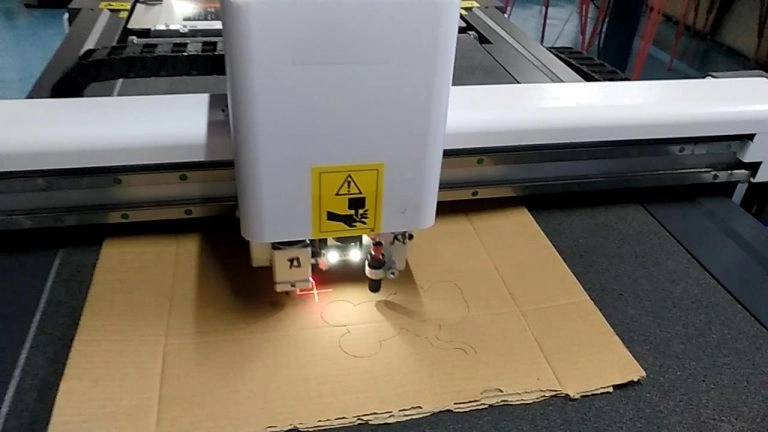

| Multiple function machine head | Easy to change different tools. Engraving and routers. Oscillating through cutting/ kiss cutting/ceasing/plotting/laser positioning, and precise camera registration. | |

| Tools | Various kinds of cutting blades, different size of creasing wheels. | |

| Safety device | Infrared sensor, responsive, safe and reliable | |

| Moving speed | Up to 1500mm/s | |

| Cutting speed | Up to 1200mm/s(depend on the kinds of material) | |

| Cutting thickness | ≤50mm(customized according to different materials) | |

| Cutting material | All kinds of corrugated paperboard, grey board, KT board, PVC expansion sheet, honey comb board, car sticker, light slide, PP gum, flex banner, flag fabric, EPE foams, EVA, PVC plate, acrylic, thick foam, etc | |

| Cutting material affixed | Smart (optional) individual multi-zone vacuum suction | |

| Repeatability | ±0.05mm | |

| Interface | Ethernet port | |

| Numerical control panel | Multi-language LCD Touch Scream | |

| Transmission | Imported (digital servo motors, straight rail, synchronous belt, guide screw) | |

| Related powder | 9.5 kw | 9.5 kw |

| Related voltage | 380V/220V±10%, 50hz/60hz | |

| Max. cutting size | 2500mmx1300mm | 2500mmx1600mm |

| Machine size | 3650mmx2320mmx1280mm | 3650mmx2620mmx1280mm |

2. Core technology

- High end 6-axis speed motion control system.

- Integrated softwares control of high performance

- High standard design for long time batch production

- Conveying flatbed design, with optional automatic board loading system, achieves automatic production of rolls and board material, shortening tack time and improving efficiency.

- Digital fine tuning for kiss-cut and thorough cut, dotted line and creasing.

- New intelligent sub-area vacuum suction with high suction force(small cutting material appressed closely anf firmly to the mat easily)

3. STANDARD TOOLS CONFIGURATION

Two multi-tool module / Plotting Pen / Laser Locating Pointers (For manual alignment) / Proximity Sensor and Emergency Stop / Vacuum Table with individul area vacuum pump / Auto-Cut Deph Setting Device

Touch Screen Controls / Sound Absorber / Air Compressor / Software with dongle

4. Cutting material

All kinds of corrugated paperboard, grey board, KT board, PVC expansion sheet, honey comb board, car sticker, light slide, PP gum, flex banner, flag fabric, EPE foams, EVA, PVC plate, acrylic, thick foam, etc

5.About our factory

EcooGraphix TD790 is produced by the leading manufacture in China ,which has a long history more than 90years. It is the first factory to produce and supply the Die Cutting ,Foil Stamping and Automatic Gluing machines .There are thousands of Die Cutting Machines installed worldwide. And two units EcooGraphix TDS790 were installed in Hungary in 2017.

6.Quality Control

Professional control department which is responsible for all the machines.

Full checking list including mechanical and electrical detection on the machine.

Strict standard for registration and over 24 hours non-stop running on each machine.

Follow the policy of 'One person responsible for one machine' ,'Claim responsibility if machine has assemble problem'.

7.Service

All of our technicians have over 10-20 years experience.

Rich experience in installation, repairing and maintenance overseas.

After-sales staff Whatsapp/Wechat on line 24/7.

Guarantee to provide after-sales service for any machine for whole using life.

RFQ

- Warranty

- Certificate

- Installation and training

- Lead time?

- Payment term?