- Overview

- Product Description

- Product Parameters

- Detailed Photos

- Work Piece

- Packaging & Shipping

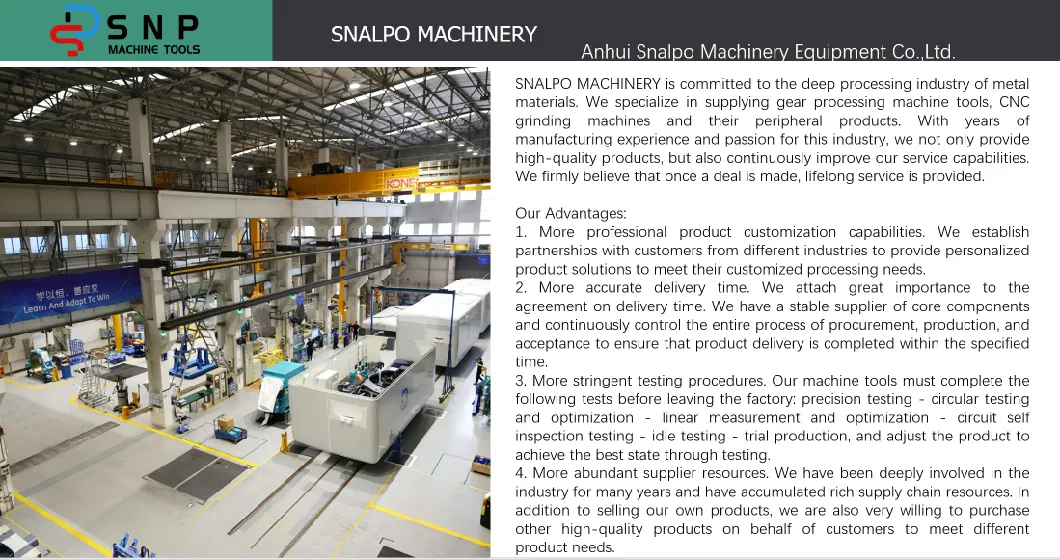

- Company Profile

- Hot Products

- FAQ

Basic Info.

Product Description

CNC Gear Hobbing Machine G180 Advantages

CNC Gear Hobbing Machine G180 Advantages

1:The hob spindle adopts imported water-cooled servo motor direct drive, which has the characteristics of small volume and high efficiency. The workpiece spindle adopts a built-in torque motor for direct drive, and is equipped with a constant temperature cooling device and a full closed-loop control of a circular grating to ensure high-precision processing.

2:The X,Z-axis adopts precision ball screws and linear roller guides to ensure the positioning accuracy and stiffness of the machine tool.

3:The Y-axis adopts a servo motor to drive precision cutting, achieving uniform wear of the blade and improving the service life of the tool.

4:Standard servo tailstock with high clamping force, suitable for quick clamping of disc-shaped workpieces. Can process cylindrical gears, worm gears, sprockets, toothed synchronous pulleys, flexible pulleys, and splines and other types of workpieces.

5:Equipped with powerful, user-friendly, and user-friendly gear machining application software, it can achieve parameterized programming, tooth profile modification, and micro compensation.

| CNC Gear Hobbing Machine G180 main technical parameters | ||

| MAX. Work Diameter | Φ180 | mm |

| Max. Work Module | 4 | mm |

| Max. Workpiece Spindle Speed | 600 | r/min |

| Max. Hob Spindle Speed | 2200 | r/min |

| Hob Shifting length | 150 | mm |

| Z-Slide Travel | 300 | mm |

| Hob Head Swing Angle | ±45 | ° |

| Max. Hob Size | Φ110*160 | mm |

| Total Power | 30 | kva |

| Machine Size | L2270*W2580*H2760 | mm |

| Machine Weight | 7000 | kg |