Basic Info.

Model NO.

B Type

Storage Environment

Dry Environment

Product Specifications

70mmw*550mml

Weight

2.2kg

Transport Package

Carton & Vacuum Packing

Specification

720*150*200mm

Trademark

WYC

Origin

China

Production Capacity

5000000pieces/Year

Product Description

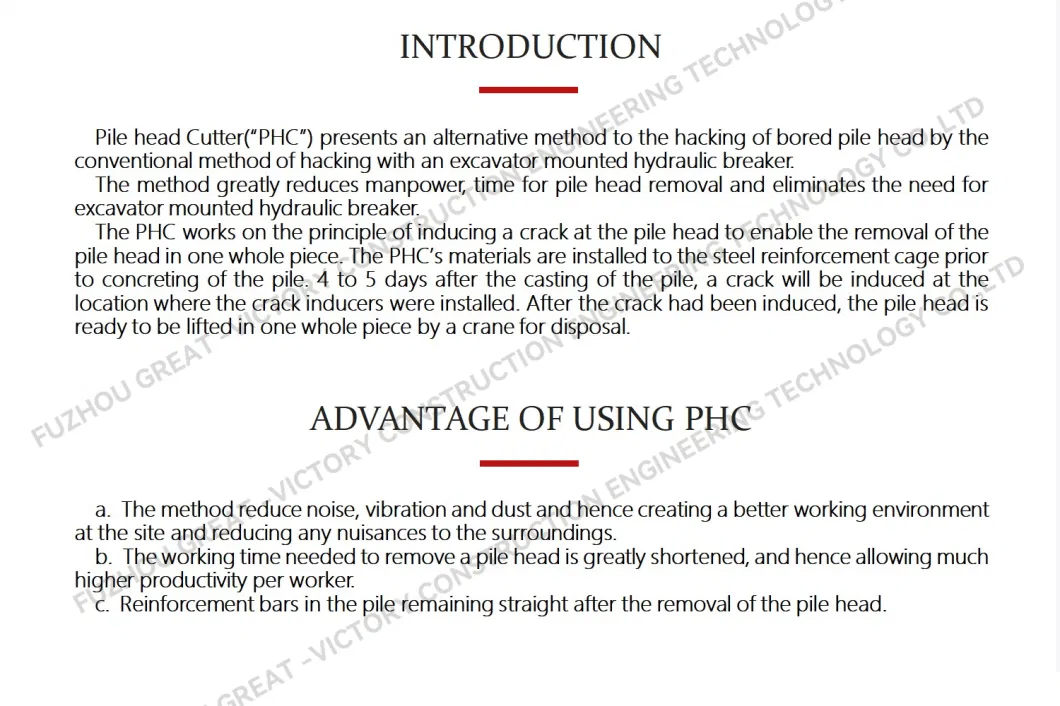

PILE HEAD CUTTER("PHC")

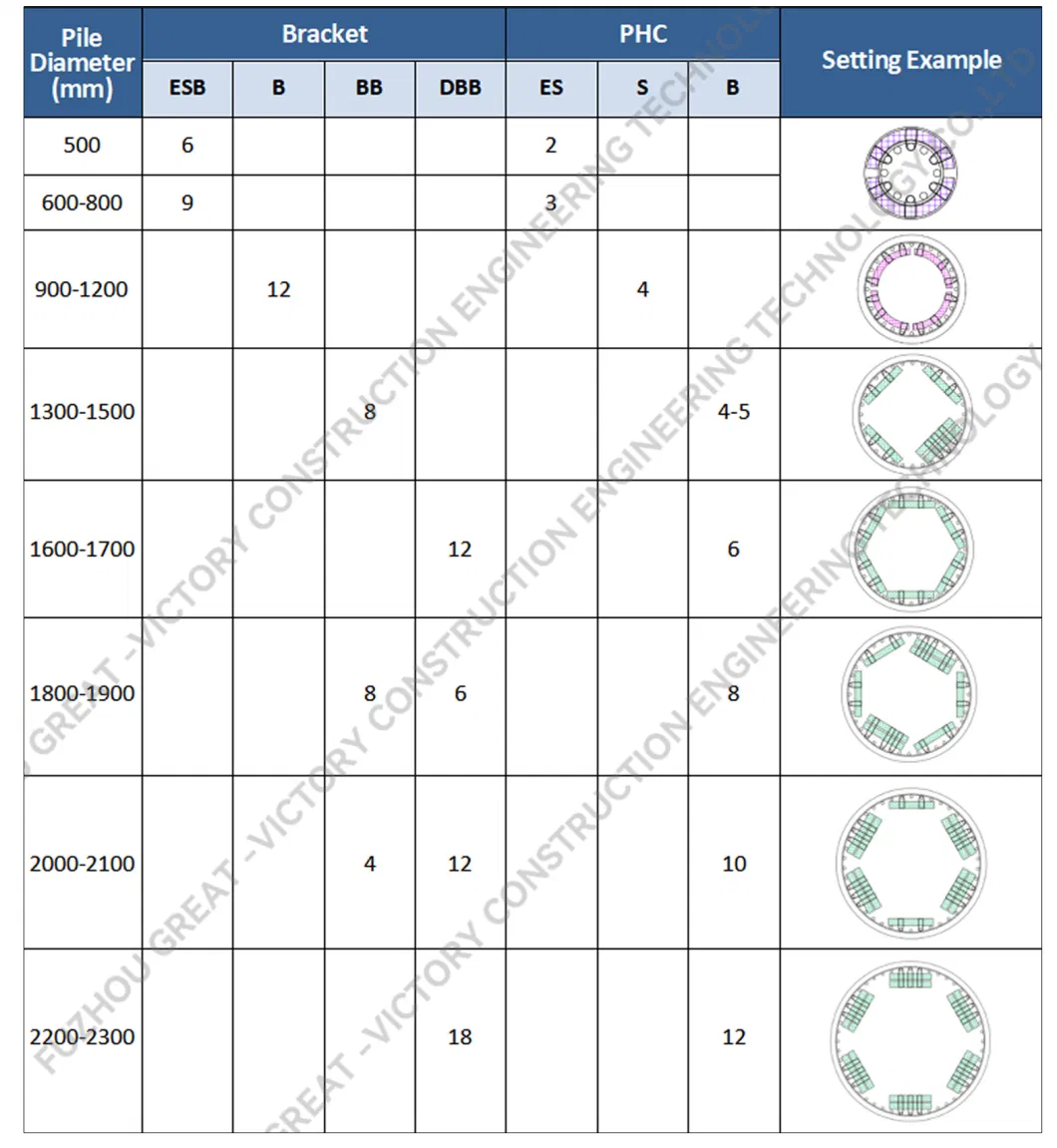

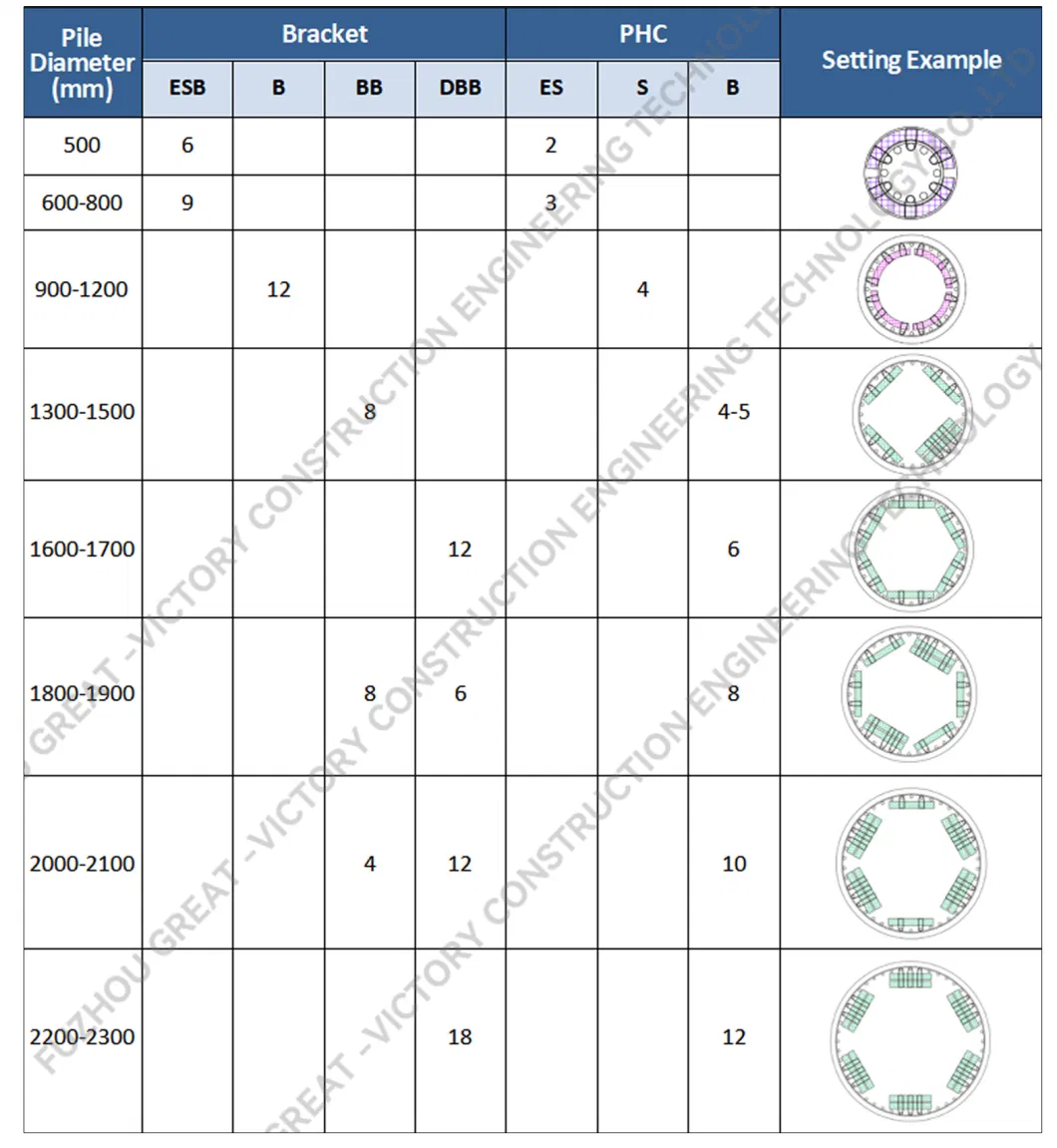

| NAME | APPLICATION | PACKING | |

| PHC(ES) | Small cut pile head | Ф500mm-Ф800mm | 600×35mm×10pcs |

| PHC(S) | Large cut pile head | Ф900mm-Ф1200mm | 700×45mm×10pcs |

| PHC(B) | Large cut pile head | Ф1300mm or more | 550×70mm×10pcs |

| NAME | ACCESSORY | |

| For PHC(ES) | Bracket type ESB | The brackets are then fixed to the steel reinforcement cage,with the PHC at the level that the crack should form in the pile head |

| For PHC(S) | Bracket type B | |

| For PHC(B) | Bracket type BB/DBB | |

De-bonding foam

| NAME | REMARKS |

| De-bonding foam for vertical reinforcement anchor bar | There are five sizes with a diameter of 16-40mm |

How the PHC Works

1. The bonding between concrete and steel is removed by covering all reinforcement bars with de-bonding covers.

2. The PHC that is installed with the water in the concrete and expand. The expansion will cause stresses in the concrete that has set. The expansive stresses will exceed that of the compressive stress of the concrete after 3 to 4 days and hence causing a crack in the pile head.

3. The cracking of the pile head at the position of the PHC will hardly propagate below the intended cracking line.

Components

1. PHC

a) Type ES-35mmWx600mml

b) Type S-45mmlWx700mml

c) Type B-70mmWx550mml

2. Steel Reinforcement De-Bonding Covers

Various sizes - From Φ16mm to Φ40mm 3. Steel Brackets

a) Type ESB

b) Type SB

c) Type BB

d) Type DBB

b) Type SB

c) Type BB

d) Type DBB

a) 5C-W130mm-L1100mm

b) 5C-W140mm-1400mm

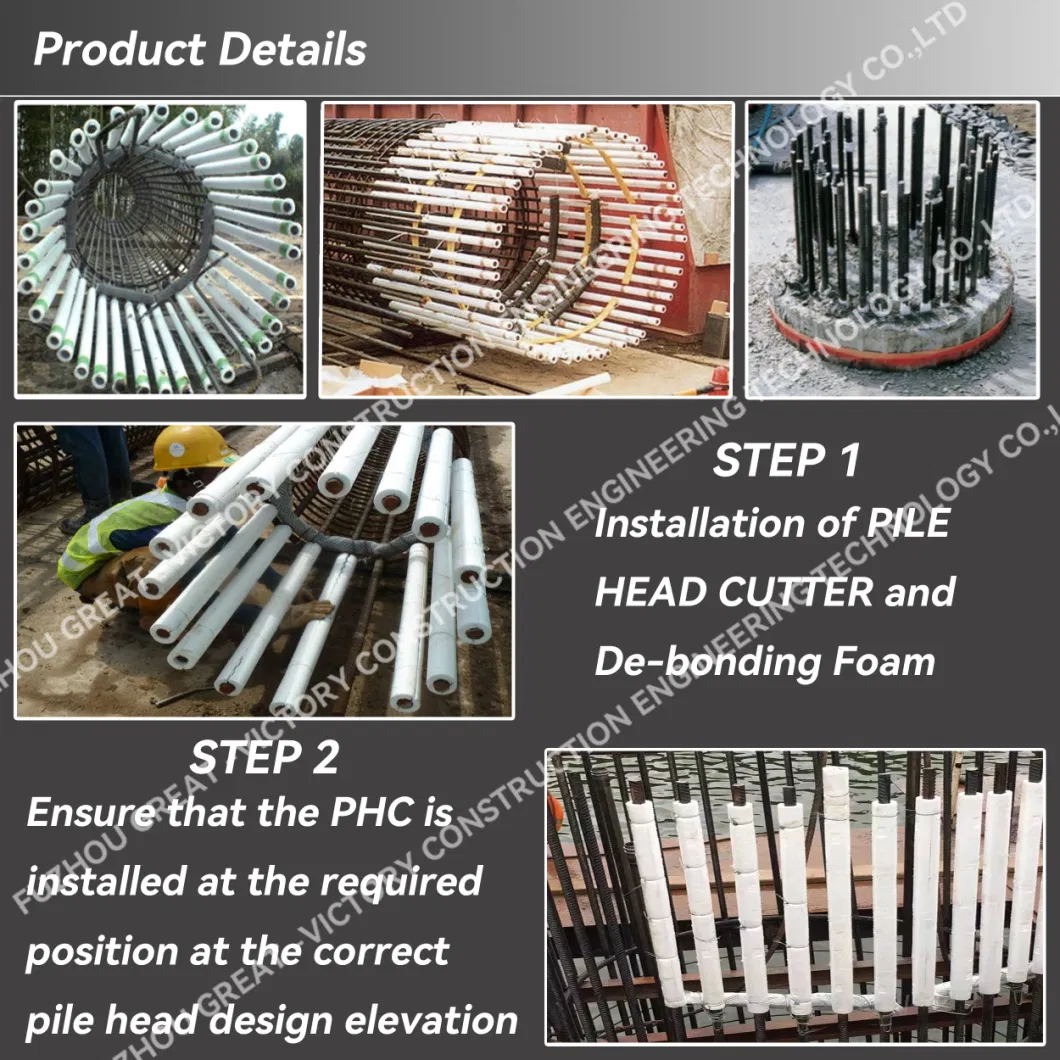

Installation Procedure

1. The PHC materials are fixed to the steel Reinforcement cage prior to lowering the cage into the bored hole for concerting.

2. The PHC are initially fitted to the steel brackets.

3. The steel brackets are then fixed to the steel reinforcement cage,with the PHC at the level that the crack should form in the pile head.

4. Install de-bonding covers to all the steel Reinforcement starter bars above the PHC.

5. The installation of the PHC is complete and ready to be installed into the bored hole for concreting.

2. The PHC are initially fitted to the steel brackets.

3. The steel brackets are then fixed to the steel reinforcement cage,with the PHC at the level that the crack should form in the pile head.

4. Install de-bonding covers to all the steel Reinforcement starter bars above the PHC.

5. The installation of the PHC is complete and ready to be installed into the bored hole for concreting.

Pile Head Removal

1. After concreting, wait 4 to 5 days for crack to form at the pile head.

2. When the crack at pile head has formed, the pile head can be removed by lifting it off with crane, when necessary with the aid of an excavator.

CONFIGURATION OF PHC FOR EACH PILE SIZE

Q: Why choose our product?

Q: Why choose our product?

A: Reduce labor costs, improve efficiency, save time, reduce noise, and be more environmentally friendly.

Q: Are you a manufacturer?

A: Yes,our factory was established in 2011 and we have our own trading company.

Q: What's the MOQ and payment terms?

A: MOQ is 20 pieces. Payment via T/T.

Q: How about delivery time?

A: 15-30 work days after the payment, and also depend on your quantity.

Q: How long is the shelf life of the product?

A: In a dry environment 6-8 month.

Q: Which country have you exported?

A: Most Southeast Asian countries.

Q: Why choose our product?

Q: Why choose our product? A: Reduce labor costs, improve efficiency, save time, reduce noise, and be more environmentally friendly.

Q: Are you a manufacturer?

A: Yes,our factory was established in 2011 and we have our own trading company.

Q: What's the MOQ and payment terms?

A: MOQ is 20 pieces. Payment via T/T.

Q: How about delivery time?

A: 15-30 work days after the payment, and also depend on your quantity.

Q: How long is the shelf life of the product?

A: In a dry environment 6-8 month.

Q: Which country have you exported?

A: Most Southeast Asian countries.