- Overview

- Product Description

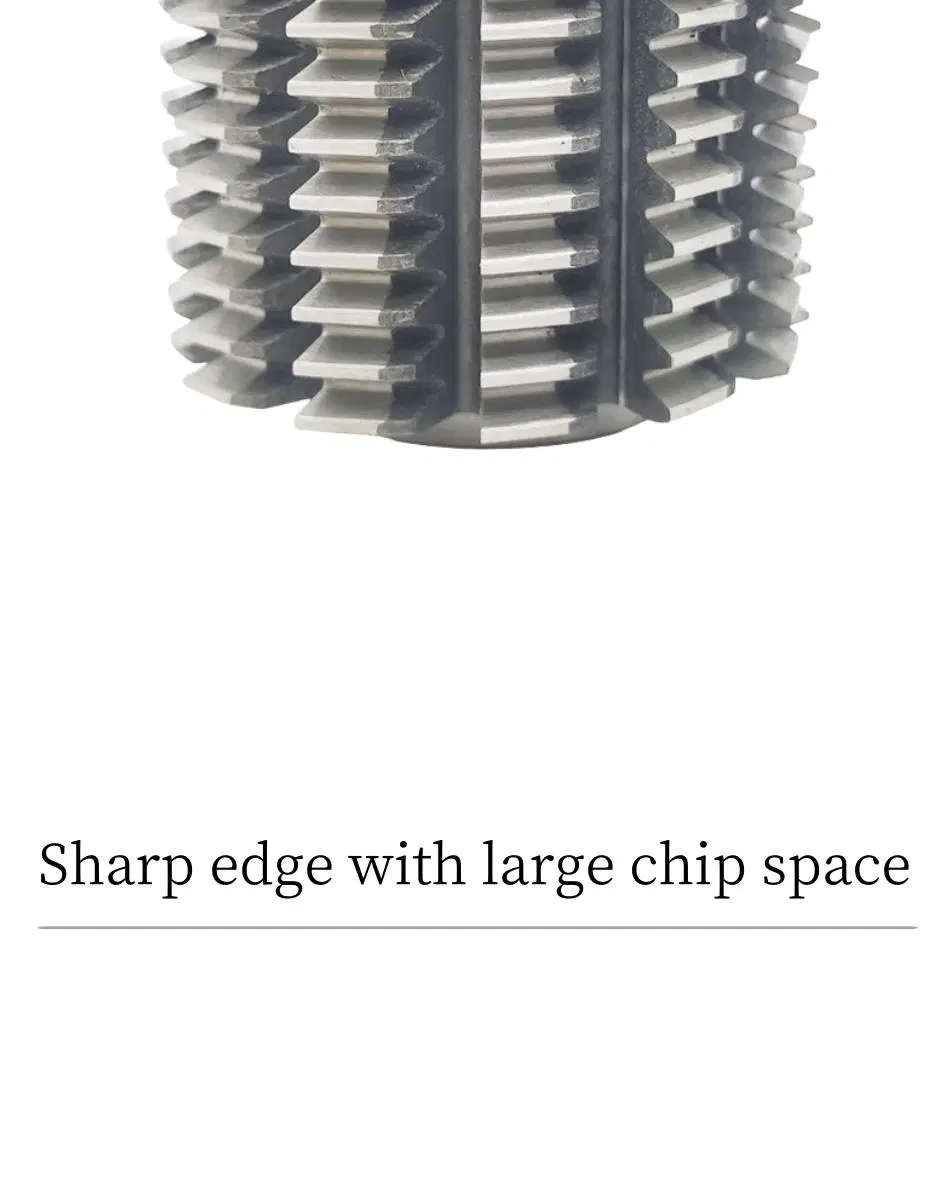

- Detailed Photos

- Product Parameters

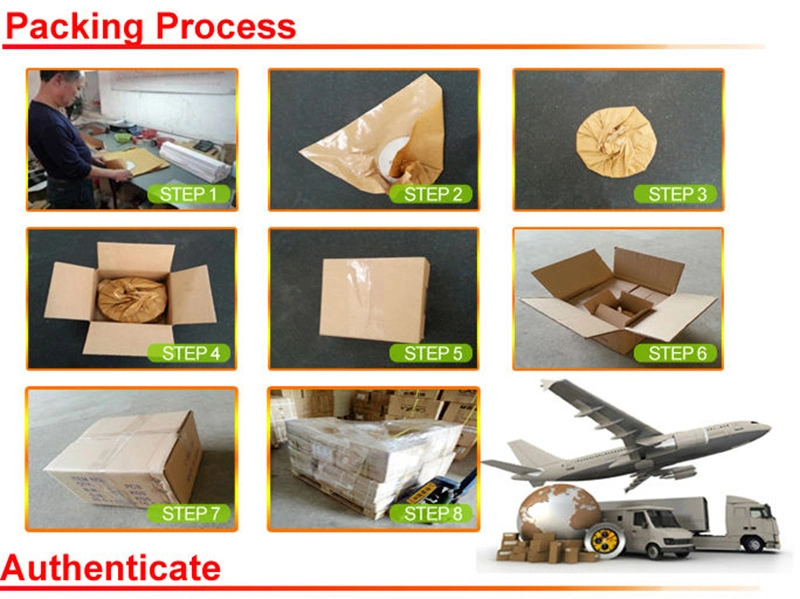

- Packaging & Shipping

- Company Profile

- FAQ

Basic Info.

Packaging & Delivery

Product Description

units:mm

| specification | outside diameter | total length | inner diameter |

| m1 | 50 | 40 | 22 |

| m1.25 | |||

| m1.5 | 63 | 50 | 27 |

| m1.75 | |||

| m2 | 63 | ||

| m2.25 | |||

| m2.5 | 70 | 70 | |

| m2.75 | |||

| m3 | 80 | 80 | 32 |

| m3.25 | |||

| m3.5 | |||

| m3.75 | 90 | 90 | |

| m4 | |||

| m4.25 | |||

| m4.5 | |||

| m5 | 100 | 100 | |

| m5.5 | 112 | 112 | 40 |

| m6 | |||

| m6.5 | 125 | 125 | |

| m7 | |||

| m8 | 130 | 130 |

Note:

Special worm gear hobs with circular tooth, double pitch and involute etc. can also be ordered.

Hob cutter series : gear hob , pre-shaving gear hob, pre-grind gear hob, involute spline hob, parallel side spline hob, ground sprocket hob , and timing pulley hob.

Material Introduction:

A. W6Mo5Cr4V2 (GB) M2( ASTM), S6-5-2(DIN), SKH51(JIS)

chemical composition:C 0.85, Si 0.38, Mn 0.35, P≤0.030, S≤0.030, Cr 4.10, W 6.00, Mo 4.80 V 1.85

main application:It is widely used for making all kinds of cutters and durability cold-work die

B. W6Mo5Cr4V2Co5 (GB), M35( ASTM), 1.3243(DIN), SKH55(JIS)

chemical composition: C 0.93, Si 0.38, Mn 0.35, P≤0.030, S≤0.030, Cr 4.10, W 6.30, Mo 4.80 V 1.85, Co 5.00

main application:It is often used for making blades with high-speed and great cutting difficulty as it's good abrasive resistance

W6Mo5Cr4V2(M2),W9Mo3Cr4V(W9),W18Cr4V(W18),W6Mo5Cr4V2Al(M2Al),W6Mo5Cr4V2Co5(M35),W2Mo9Cr4VCo8(M42),W4Mo3Cr4VSi(4341),W4Mo2Cr4VSi(4241)

1.For the loose cargo we will packing by wooden box

2.For the full container loading we are packing the machine by film and some on pallet accordingly

3.We can shipping the goods by air or by sea

4.We will send pictures of cargo loading to our client to check and keep recording

5.We can send cargo to client's warehouse to loading

.

Q1: Are you trading company or manufacturer ?

A1: Our factory is a professional manufacturer of machinery blades.Our blades are mainly used in: packaging, paper, rubber, optoelectronics, electronics, light industry, printing, metallurgy, and other machines.

Q2: what is your blade hardness?

A2: Different material has different hardness, from 48HRC to 68HRC, we both have. You can advice the function of your blade, we can provide suitbale suggestion for you.

Q3: What is your advantage if I choose you?

A3: 1. End manufacturer with competitive factory price.

Q4: How long is your delivery time?

A4: Generally it is 3 days if the goods are in stock. or it is 15-45 days if the goods are not in stock, it is according to quantity.

Q5: Do you provide samples ? is it free or extra?

A5: Yes, we could offer the sample for free charge but freight cost by yourself.

Q6: What is your terms of payment ?

A6:100%, or 50% T/T in advance, balance before shipment.Also can pay by Credit Card,Paypal so on.