- Overview

- Product Parameters

- Related Product:

- FAQ

- Buyer recommend products

Basic Info.

Packaging & Delivery

Product Description

Hot Selling America Use Automatic Hydraulic Wood Sawmills

Combined with hydraulic automation technology, the hydraulic horizontal band sawmill realizes all-digital intelligent control. Chinese and English operating system, automatic wood rotation, sawing and cutting of large diameter wood, simple operation of equipment, precise cutting thickness, improves wood usage rate.

Configure of AUtomatic Hydraulic Portable Sawmill

SPECIFICATIN OF HORIZONTAL WOOD SAWMILL MACHINE PRICE

| Model | LBJ-1000A | LBJ-700A |

| Max sawing wood diameter | 1000mm | 700mm |

| Saw wheel diameter | 700mm | 700mm |

| Max sawing wood thickness | 300mm | 300mm |

| Max sawing wood length | 4500mm | 4500mm |

| Main Power | 22KW (3Phase/3380V/50HZ) | 18.5KW |

| Hydraulic Power | 4KW(3Phase/3380V/50HZ) | 3KW |

| Band saw blade width | 40-80MM | 40-80MM |

| Machine length | 6000MM | 6000MM |

| Weight | 3500KG | 3000KG |

Hot Selling Portable Horizontal Wood Sawmill

- APPLICATION RANGE:

1). Portable Horizontal Band sawmill is to meet the requirements of customers in Africa and South America.

2). It is simple installation, easy operation, labor saving and high productivity.

3). This machine can be drove by either electric motor or diesel engine

4). It is widely used by the timber process enterprises in the virgin forests area.

Technical parameter of wood sawmill machine price

| Model | LBJ-700E | LBJ-1000E | LBJ-1300E | LBJ-1600E | |

| Max. Sawing Wood Diameter | 700MM | 1000MM | 1300MM | 1600MM | |

| Saw Wheel Diameter | 600MM | 700MM | 700MM | 700MM | |

| Sawing Wood Thickness | 260MM | 300MM | 300MM | 300MM | |

| Sawing Wood Length | 4500MM | ||||

| Power | 15KW/22HP | 18.5KW/22HP | 22KW/25HP | 30KW/27HP | |

| Up/Down Motor | 1.1KW | ||||

| Total Weight (KG) | 900 | 1100 | 1300 | 1500 | |

Disel Engine Type Portable Sawmills

Electric Motor Type Portable Sawmill

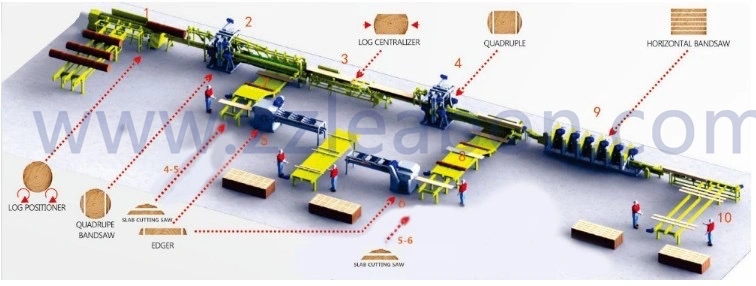

Hot Selling Complete Wood/Logs Cutting Line

Introduction of double vertical type saw

1.This twin vertical sawmill is a special equipment for processing wood logs, it can cuts the round wood log into square wood.

2. Easy installation and operation, large output.

3. It is suitable for cutting logs and used in the production of furniture.

4. Machines with different sizes meet the requirements of different customers and are often used in Africa, South America and other regions.

Technical Parameter of Vertical Wood Sawmill:

| Model | LBLS-350 | LBLS-500 |

| Max sawing wood diameter | 350mm | 500mm |

| Min Sawing Wood Diameter | 100mm | 100mm |

| Sawing Wood Length | 1000-3000mm | 1000-3000mm |

| Feeding Speed | 9-25Meters/Minute | 9-25Meters/Minute |

| Conveyor Length | 7000mm | 3500*2mm |

| Saw Wheel Diameter | 700mm | 760mm |

| Saw wheel diameter | 50-80mm | 50-100mm |

| Motor | 2*18.5KW | 2*22KW |

| Feeding Motor | 5.5KW | 4KW*2 |

| Sizing Control | Touch Screen | Touch Screen |

| Parameter | LBMS 120-250 | LBMS 160-250 | LBMS200-250 | LBMS160-350 |

| Max. sawing wood plate width | 250mm | 250mm | 250mm | 350mm |

| Max. sawing wood plate thickness | 120mm | 160mm | 200mm | 160mm |

| Sawing wood plate length | More than 500mm | More than 500mm | More than 500mm | More than 600mm |

| Speed of main shaft | 2800 r/min | 2800 r/min | 2800 r/min | 2800 r/min |

| Main motor power | 15KW*2 | 18.5KW*2 | 22KW*2 | 30KW*2 |

| Feeding motor power | 1.5KW | 1.5KW | 2.2KW | 2.2KW |

| saw blade diameter | 212mm | 255mm | 305mm | 255mm |

| saw blade quantity | 2-10pieces | 2-10pieces | 2-10pieces | 2-10pieces |

| saw blade arrangement | Two group of blades | Two group of blades | Two group of blades | Two group of blades |

| Feeding speed | Frequency control | Frequency control | Frequency control | Frequency control |

| Cooling water pressure | 0.3-0.6PA | 0.3-0.6PA | 0.3-0.6PA | 0.3-0.6PA |

| Cooling method | Axial water | Axial water | Axial water | Axial water |

3. Final Cutting Wood Planks :

When palacing the order for sawmill machinery price, pls make sure the following:

1. What's your raw material for processing ? Roung Logs or Square wood plank?2. What's the size of your raw material? (Round wood: diameter and length; Square wood plank: width and length)

3. What's the size of final wood board you want to cutting ?(Length*Width*Thickness)

4. How many CBM wood/wood planks you want to processing per day?

5. What's the usage of final wood board product?