Basic Info.

Model NO.

1530

Layout

Vertical

Cutting Material

Copper, Carbon Steel, Iron, Aluminum, Metal Alloy, Stainless Steel

Automatic Grade

Automatic

Power Source

Electric

Cutting Mode

Support Plasma Cutting and Gas Cutting

CNC System

Beijing Start CNC

Motor and Driver

Servo Motor/Stepper Motor

Software

Fastcam Software

Cutter Torch Cooling Method

Air Cooling or Water Cooling

Current

30-400A Plasma Cutter Source

Nest Software

Fastcam

Pipe Cutting

Round Pipe Cutting

Plasma Power

120A 200A 300A

Name

CNC Plate & Pipe Cutting Machine

Cutting Model

Pasma Cutting, Flame Cutting

Lathe Bed

Steel Structure with Water Sink

Control System

Starfire/Start Control System

Plasma Source

Huayuan / Hypertherm

Transmission

Ball Screw, Hiwin Linear Rails

Machine Name

Pipe Plasma Cutter

Transport Package

Wooden Box

Specification

2030

Trademark

ALLWIN

Origin

China

HS Code

8456909000

Packaging & Delivery

Package Size

300.00cm * 200.00cm * 150.00cm

Package Gross Weight

1000.000kg

Product Description

Features of cnc plasma cutter

1. Plasma power and cutting gun with high quality, made by famous factories in China.

2. Cutting mouth, little and tidy and avoid second trimming.

3. Applied for metal sheet, aluminium sleet, stainless sheet, Titanium sheet and so on

4. High cutting speed, high precision, and low cost.

5. Plasma power: 20A-60A / 380V, the plasma power can be adjusted.

6. Plasma source adopts advanced integrated module control system, it ensures the high precision and stability.

7. With unique handling with breakpoint and interruption of power supply, it can move forward and backward according to the track.

8. Support Wentai, ARTCAM softwares, Type3 produce standard G code way document, also can change software to read AUTOCAD softwares

9. The control system uses the U-disk exchange processing document, easy to operate.

10. When machine working with water pump and tank provide circulating water cooling.

11. Difference with other factory plasma cutting machine, this machine use screw-ball as drive mode, whic provide high precision for this machine.

Parameter:

Package of cnc plasma cutter

Water-proof plastic film package with foam protection in each corner.

Solid Seaworthy Wood Box Package with Steel Belt.

Save space as much as possible for container loading.

Our Services

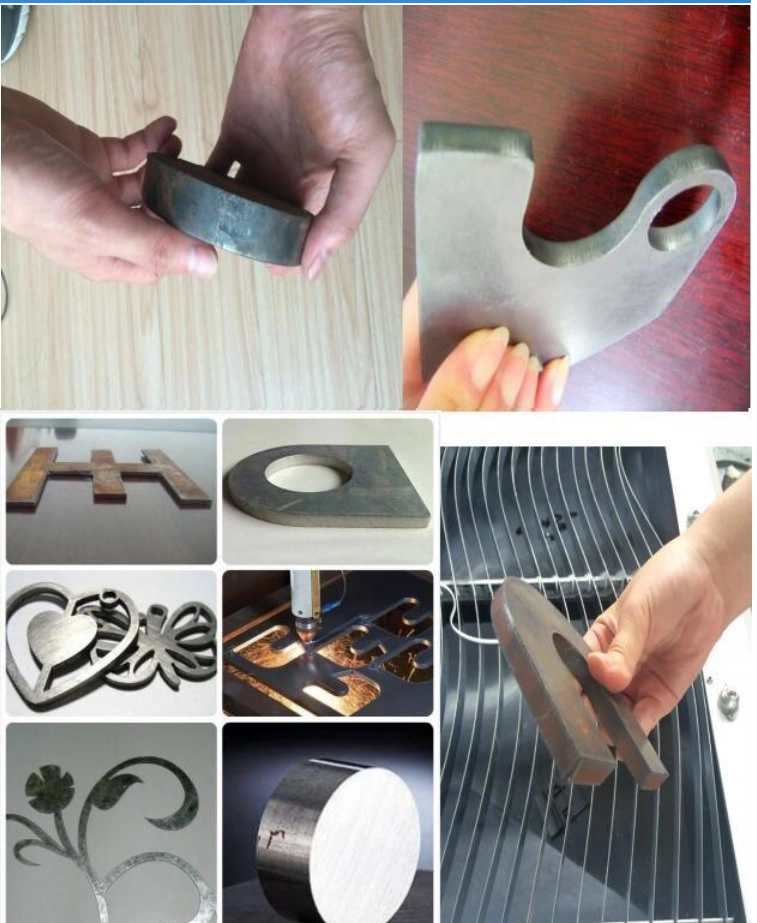

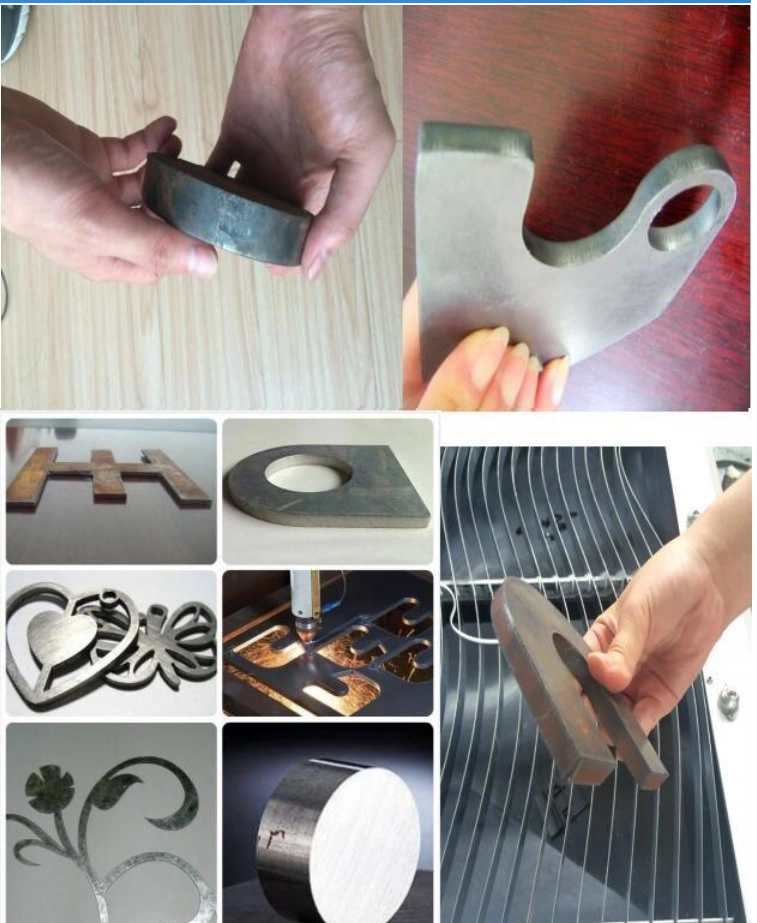

Sample of plamsa machine

CERTIFICATE:

FAQ for CNC plasma cutting table:

Q: Do you have after-sale service and support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running.

Q: I am not sure if this CNC plasma cutting machine suitable for my work?

A: Don't worry, just tell me your working materials, max working area and cutting thickness, then I will recommend you the most suitable machine for you.

Q: What other things also need after we bought your CNC plasma cutting machines?

A: With plasma cutting: need plasma power source and air compressor. You can match plasma power supply by yourself, or buy together with the cutter from us, it's optional. If you buy from us, we will connect the wires of plasma power source and CNC plasma cutting machine together, then more conveniently to use.

Q: How can I do if the machine goes wrong?

A: If confronted with such problems, online service is offered, you could contact our sales. Also, we offer engineer delivery service. Please contact us ASAP and don't try to fix the machine by yourself or someone else. We will response as soon as we can to solve it for you.

1. Plasma power and cutting gun with high quality, made by famous factories in China.

2. Cutting mouth, little and tidy and avoid second trimming.

3. Applied for metal sheet, aluminium sleet, stainless sheet, Titanium sheet and so on

4. High cutting speed, high precision, and low cost.

5. Plasma power: 20A-60A / 380V, the plasma power can be adjusted.

6. Plasma source adopts advanced integrated module control system, it ensures the high precision and stability.

7. With unique handling with breakpoint and interruption of power supply, it can move forward and backward according to the track.

8. Support Wentai, ARTCAM softwares, Type3 produce standard G code way document, also can change software to read AUTOCAD softwares

9. The control system uses the U-disk exchange processing document, easy to operate.

10. When machine working with water pump and tank provide circulating water cooling.

11. Difference with other factory plasma cutting machine, this machine use screw-ball as drive mode, whic provide high precision for this machine.

Parameter:

| SPECIFICATION | |||||

| No. | Model 1530 | CNC table plasma+flame cutter | |||

| 1 | X axis working area | 1500mm | |||

| 2 | Y Axis working area | 3000mm | |||

| 3 | Cutting Mode | Plasma +flame | |||

| 4 | Driving and motor | stepper motor86BYG450A and leadshine drive DMA860H | |||

| 5 | cutting torch | one set of Plasma torch with water-cooled | |||

| 6 | Controller system | one set of BEIJING START | |||

| 7 | Software | one set of Austraila FASTCAM | |||

| 8 | screen size | 4.7 inch | |||

| 9 | Plasma power | huayuan LGK160A with 100% rated duty cycle | |||

| requested Compressed air 0.5-0.6Mpa | |||||

| secondary arc striking with high voltage non-contact | |||||

| 9 | Torch height controller | Automatic THC for plasma | |||

| Mechanical controlled THC for Flame | |||||

| 10 | input power | 1 phase AC 220V for CNC machine | |||

| 3 phrase AC 380V for plasma power | |||||

| 11 | the way of Clean smoke | Air fan | |||

| 12 | tramsmission method | USB | |||

| 13 | programe software | AutoCAD | |||

| 14 | quality cutting thickness for plasma | 25mm | |||

| 15 | manual cutting thickness for plasma | 35mm | |||

| 16 | flame cutting thickness | 20mm-100mm | |||

| 17 | flame cutting speed | 0-3500mm/min | |||

| 18 | Linear guide | HIWIN square Guild rail 2.0 | |||

| 19 | Electrical components | CHINT | |||

| 20 | Package size(L*W*H) | 6400MMX2200MMX1700MM | |||

| 21 | Attachment parts | without Rotary Axis | |||

| With Flame cutting system | |||||

| without Drilling heads | |||||

| without Air compressing machine | |||||

Package of cnc plasma cutter

Water-proof plastic film package with foam protection in each corner.

Solid Seaworthy Wood Box Package with Steel Belt.

Save space as much as possible for container loading.

Our Services

# One year warranty for the machine

# Replacing all parts for free during warranty

# If nessessary, provide door to door service to your country

# 12 hours on line service

# Replying your email and offer tecnical service within 24 hours

Sample of plamsa machine

CERTIFICATE:

FAQ for CNC plasma cutting table:

Q: Do you have after-sale service and support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running.

Q: I am not sure if this CNC plasma cutting machine suitable for my work?

A: Don't worry, just tell me your working materials, max working area and cutting thickness, then I will recommend you the most suitable machine for you.

Q: What other things also need after we bought your CNC plasma cutting machines?

A: With plasma cutting: need plasma power source and air compressor. You can match plasma power supply by yourself, or buy together with the cutter from us, it's optional. If you buy from us, we will connect the wires of plasma power source and CNC plasma cutting machine together, then more conveniently to use.

Q: How can I do if the machine goes wrong?

A: If confronted with such problems, online service is offered, you could contact our sales. Also, we offer engineer delivery service. Please contact us ASAP and don't try to fix the machine by yourself or someone else. We will response as soon as we can to solve it for you.