Basic Info.

Model NO.

GEEPRO

Package

Standard Exporting

Delivery

45-55days

Service

Over Sea Service

Weight

About 4600kg

Transport Package

Standard Export Box

Specification

standard

Trademark

qcmt

Origin

China

HS Code

845969900

Product Description

This gear hobbing machine is suitable for cutting such gears and gear shafts at smaller diameter but with large modules and double-open bush-embracing structure is adopted for the rear column of this machine, which helps a lot to cut large gear shafts.

This machine is suitable for cutting such workpieces, on continuous dividing tooth methods, as cylindrical straight gears, helical gears, worm gears & sprocket wheels, synchronous pulley, spline shafts in batch and/or single production.

Besides, Herringbone gears without clearance groove can also be machined on this machine by using finger-milling cutter.

Indexing device for single tooth is designed and set on this machine to achieve milling gears circularly and automatically by using disc-type milling cutters or finger-type milling cutters.

This machine is widely used for generating gears that are used in industries of mines, steels, wind powers, ships and so on.

This machine is suitable for cutting such workpieces, on continuous dividing tooth methods, as cylindrical straight gears, helical gears, worm gears & sprocket wheels, synchronous pulley, spline shafts in batch and/or single production.

Besides, Herringbone gears without clearance groove can also be machined on this machine by using finger-milling cutter.

Indexing device for single tooth is designed and set on this machine to achieve milling gears circularly and automatically by using disc-type milling cutters or finger-type milling cutters.

This machine is widely used for generating gears that are used in industries of mines, steels, wind powers, ships and so on.

| Performance and Feature 1. With vertical design, the worktable can move in radial as radial feed movement. 2. Electrical system with fail-safe control and low failure rate is controlled by PLC of OMRON. 3. The modular valves available from Northman has high reliability and low failure rate in order to be convenient to diagnose failures and maintain hydraulic system. 4. The worktable is fitted with double-start worm as its index gearing. It is suitable for cutting the workpiece with less-teeth. 5. The hob spindle adopts circulating lubrication to ensure sufficient and reliable lubrication for spindle bearings in order to prolong their service life. Meanwhile circulating oil can quickly remove heat caused by spindle running to insure high rotary accuracy for the spindle. 6. Supply with special attachments according to the customers' special order. 7. Tangential hob head, hydraulic fixtures, workpiece arbors, live center, shift hob head. |

| YK3132 CNC 6 Gear hobbing machine with Direct Drive | ||

| The largest machining diameter | mm | 320 |

| The largest processing module | m | 6 |

| Worksurface daimeter | mm | 280 |

| The largest diameter cutter | mm | 150 |

| The biggest tool length | mm | 160 |

| The use of tool rod specifications | mm | 32/40 |

| Hob shift distance | mm | 120 |

| Highest hob shaft speed | rpm | 2000 |

| Work piece axis of the highest speed | rpm | 200 |

| Workpiece angle | ° | ±45° |

| X axis maximum fast moving speed | mm | 3000 |

| Y axis maximum fast moving speed | mm | 1200 |

| Z axis maximum fast moving speed | mm | 3000 |

| The total power of electric machine | kw | 32 |

| Machine tool appearance size | mm | 2900*1850*2550 |

| Machine weight | kg | about 10000 |

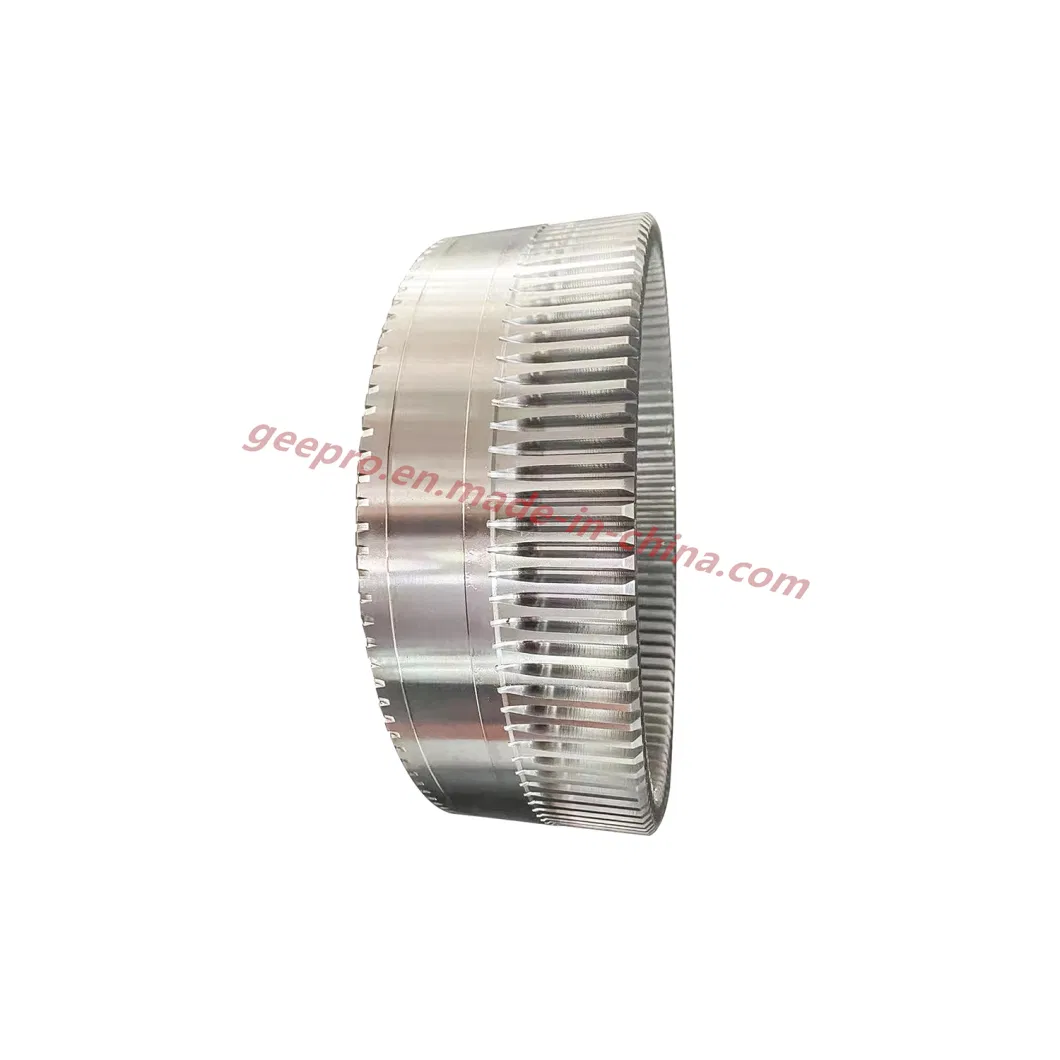

Gear Cutting Samples

Q1. How can I choose the most suitable machines ?

A: You can choose the exact model and tell us your specifications,product drawings, and detail demands.Then we will choose the most suitable machines for you.

Q2. When do you deliver?

A: It depends on the machines and model you choose. Mostly 2-3 months. All machines are manufactured according to your order. Occasionally there will be a few machines available from stock. You can send us a message or mail to check exact delivery time.

Q3. Is machine tested ?

A: The accuracy, noisy will be tested according to China GB standard.

Q4. What's the Payment Terms ?

A : T/T 30% down payment when order ,70% balance payment before shipment .

Q5. What's the MOQ?

A: 1 set.

Q6. How is the warranty?

A: 24 months after shipment date

Q7. If I have a problem setting up/ getting it running problem, will you be available by email to assist in solving the problem.

A: Yes. Video technical support, online service, we can answer you in 24 hours. And the engineers will go to your factory to solve the problems.

Q8:Can we visit your factory before ordering?

A:Sure.we are warmly welcome all of you to visit our factory. Besides, we can pick you up at the station or airport if needed. We will be very honored to help with tickets and accommodation booking.

Q9:How about your quality?

A:We have approved the ISO9001 and CE Quality management system. Most products have been approved by the European and American safety standards, our products are exported to all around the world, especially to the Europe and the Russia market, and always win high reputation. So you can rest assured of our quality products and our best services.

Q10:Can you provide customized machines?

A:Yes, we can design and manufacture according to your specific requirements.

We Can OEM Design and Manufacuring

5-axis 6 axis CNC Gear hobbing machine

Semi-automatic And Automation

Vertical,Horizontal Type Gear hobber

Spiral,Helical,Worm Gear Making

For 0.5-12m modules Cutting

Etc..

5-axis 6 axis CNC Gear hobbing machine

Semi-automatic And Automation

Vertical,Horizontal Type Gear hobber

Spiral,Helical,Worm Gear Making

For 0.5-12m modules Cutting

Etc..