Basic Info.

Model NO.

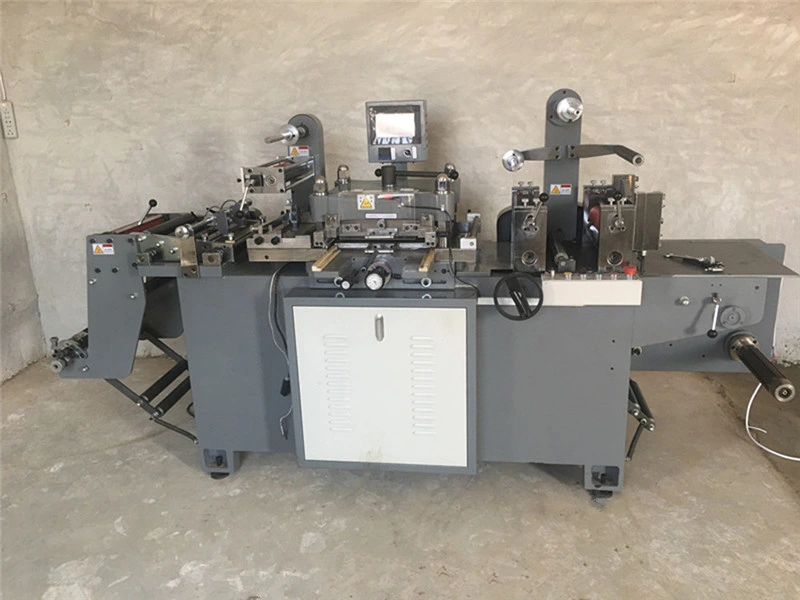

LT-500B

Application

Paper Packaging Materials, Stickers Products, Heat Insulation Material, Insulating Materials, Dust-proof Material, EMI Shielding Materials

Transport Package

Plywood Package

Specification

4300*1100*1450mm

Trademark

Longterm

Origin

Yancheng City

HS Code

8441100000

Production Capacity

500 Sets/Year

Product Description

High precision dacron film label die cutting machine

Application:

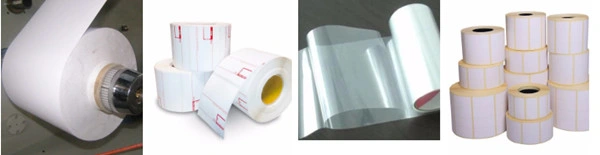

This die-cut machinery is applied in die cutting for adhesive sticker,protective film,electronic shielding material, PVC, Mylar, double sided adhesive, aluminum foil/copper foil, foam and all kinds of LCD diffuser, reflector plate, buffer plate, film, silicon adhesive tape .......

Main technical parameters:

Machine Features:

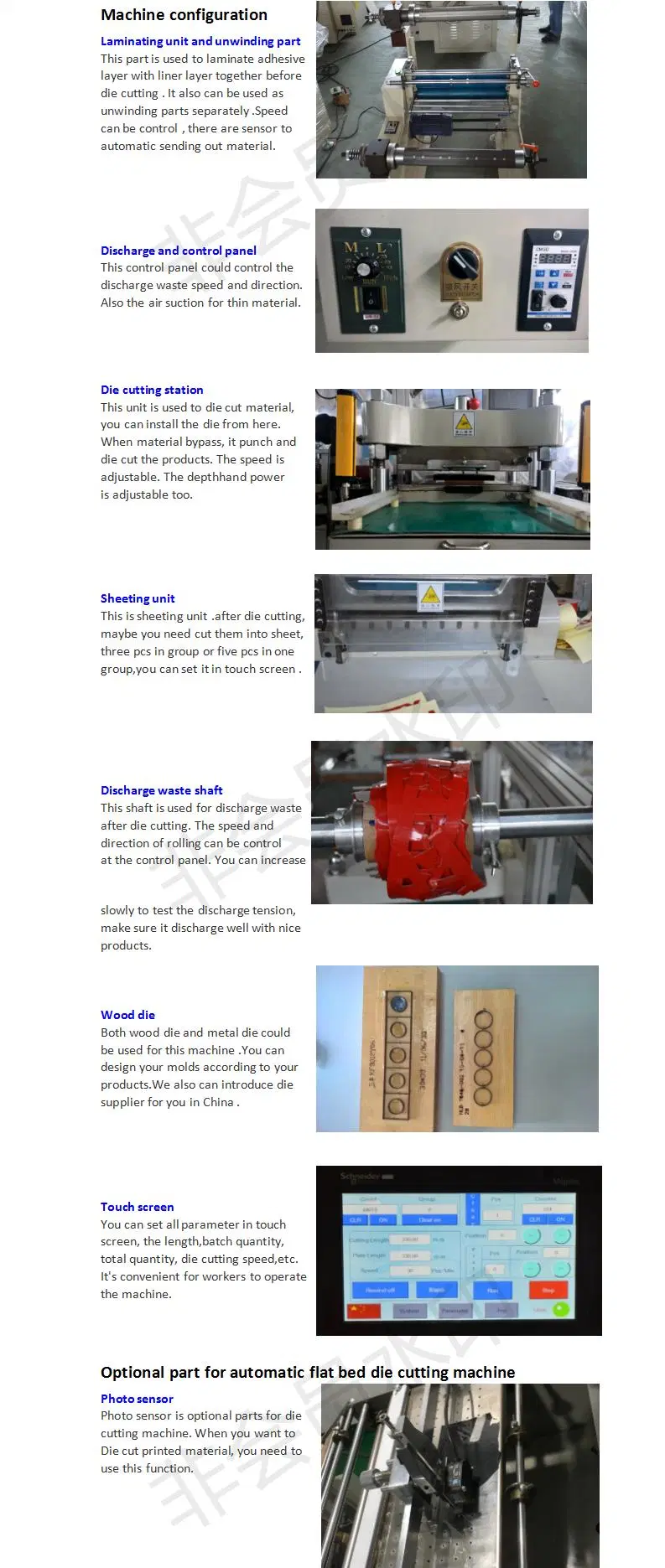

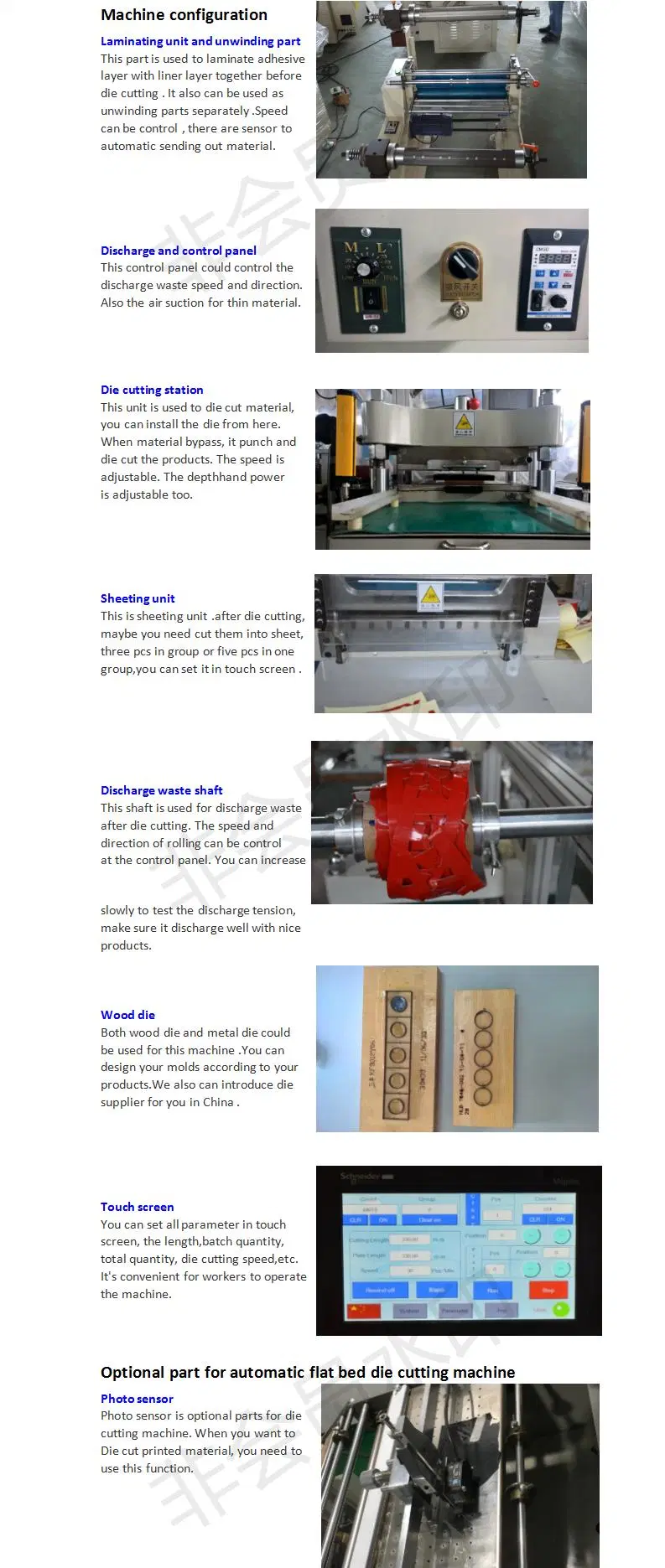

1.Multi-function in ONE machine: Laminating / partial laminating+unwinding+laminating+die cutting +discharging sheet cutting/rewinding

2.Photo Cell if necessary

3.Sucking device during material feeding process

4.Waste discharge shaft

5.Sheet cutting station

6.Rewinding station

7.Safety curtain device

8.Optional function: Conveyor belt device for full-cut use

After-sales Service

1. Warranty:1 year after you get the machine.

2. Promptly response within 24 hours in working days.

3. Free training before machine delivery and on-site training engineers available.

Application:

This die-cut machinery is applied in die cutting for adhesive sticker,protective film,electronic shielding material, PVC, Mylar, double sided adhesive, aluminum foil/copper foil, foam and all kinds of LCD diffuser, reflector plate, buffer plate, film, silicon adhesive tape .......

Main technical parameters:

| Model | LT-350B | LT-420B |

| Die Cutting speed | 20-300 cuts/min. | 20-300 cuts/min. |

| Max. unwinding diameter | 450mm | 450mm |

| Max. web width | 350mm | 420mm |

| Max. die cutting size | 330x330mm | 420x420mm |

| Precision | ±0.10mm | ±0.10mm |

| Power | 3kw | 4kw |

| Voltage | 380v | 380v |

| Machine weight | 2200kg | 2800kg |

| Machine size | 2600x950x1400mm | 2600x1050x1800mm |

Machine Features:

1.Multi-function in ONE machine: Laminating / partial laminating+unwinding+laminating+die cutting +discharging sheet cutting/rewinding

2.Photo Cell if necessary

3.Sucking device during material feeding process

4.Waste discharge shaft

5.Sheet cutting station

6.Rewinding station

7.Safety curtain device

8.Optional function: Conveyor belt device for full-cut use

After-sales Service

1. Warranty:1 year after you get the machine.

2. Promptly response within 24 hours in working days.

3. Free training before machine delivery and on-site training engineers available.