Basic Info.

Model NO.

FM1325

Customized

Customized

Condition

New

Color

Customized

Control System

DSP or Ncstudio Control

Engraving Area

1300*2500*200mm

Spindle Power

3.0kw Water Cooling Spindle

Motor Type

Stepper/Servo

Guide Rail

Taiwan Hiwin Square Linear Rail

Table Structure

Vacuum and T-Slot Table

Working Speed

8-15m/ Min

Inverter

Best / Fuling / Delta Inverter

Transmission Way

Rack Gear

Software

Artcam / Type3

Transport Package

Standard Export Wooden Case

Specification

CE, SGS, ISO

Trademark

FIRMCNC

Origin

Jinan, China

HS Code

84649012

Production Capacity

30 Sets/Month

Product Description

China sale Oscillating knife cutting machine /cnc foam cutting machine

Application of oscillating Knife cutting machine

1. It is used for carton,leather,wood,MDF,PVC etc.

2. Userfriendly Machine control interface design High efficiency of the machine help you achieve productivity leap.

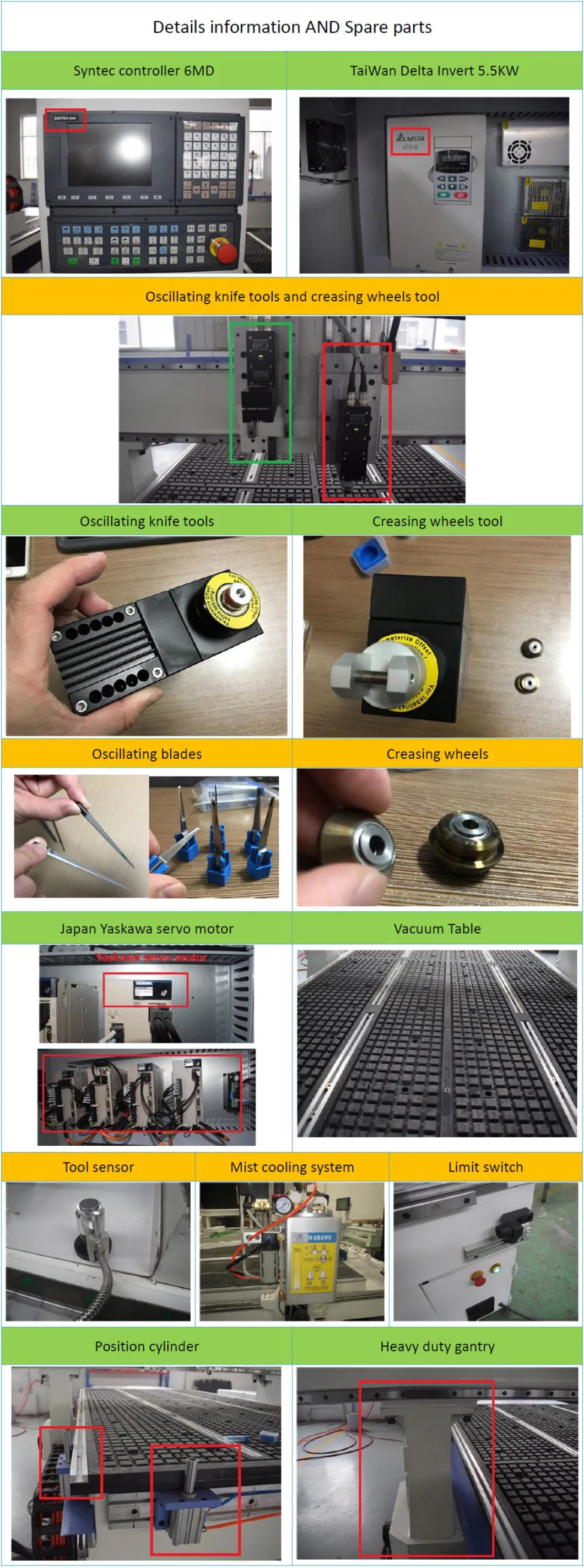

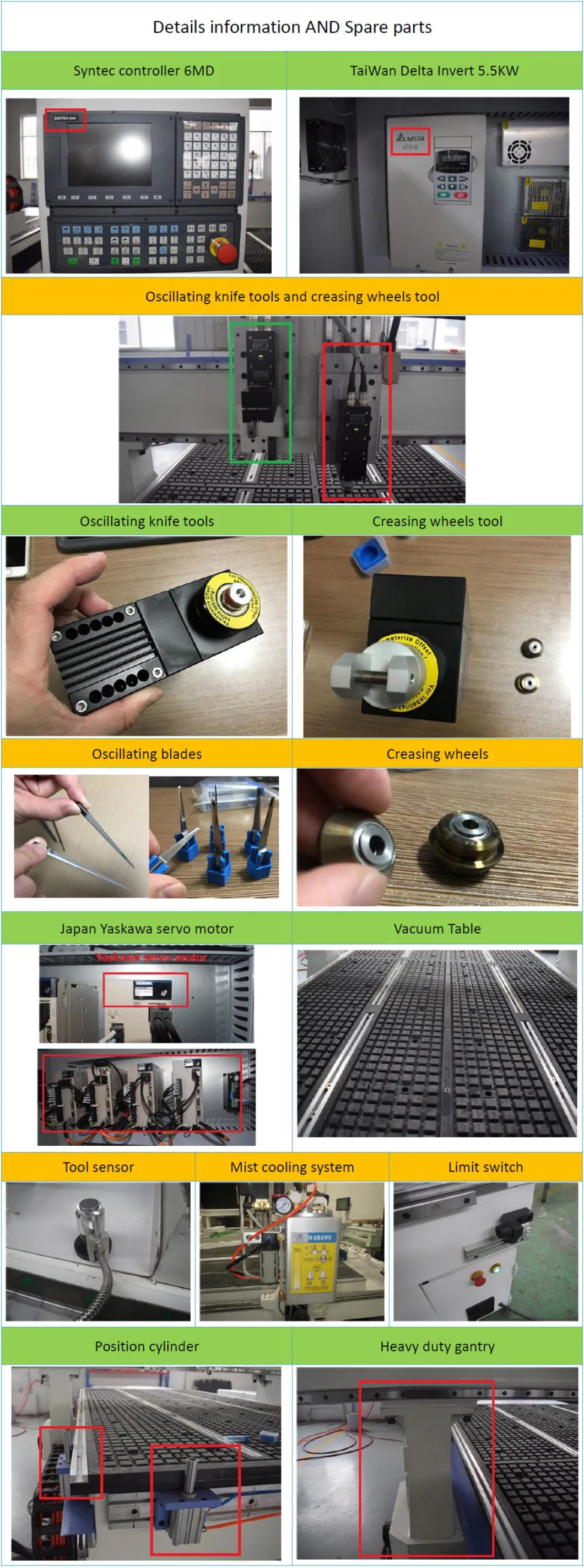

3.We use High Quality Spare parts for this machine .Such as Germany cnc oscillating tools and blade 4. Italian HSD Spindle, YASKAWA AC Servo system,German Becker Pump and so on .It is with stable performance.

Technical specification of oscillating Knife cutting machine

PS:All the working area and specifications can be customized according to your requests.

Main configuration of oscillating Knife cutting machine

Samples of oscillating Knife cutting machine

Advantage of oscillating Knife cutting machine

# Function: Extremely heavy-duty CNC machining center,suitable for routing,drilling,cutting,edge chamfering,etc.

# Construction: Whole machine table adopts high strength thick steel pipe welded.Whole working table cast by resin sand.

The annealing and other heat treatment methods ensure that the whole structure is tested to the limit for sturdiness and reliability.

# Spare parts: Features world top class mechanical and electronic components,e.g.Taiwan rail and ball screw,French Schneider electrical components,

which guarantee stable performance and high quality.

# Precision: Excellent spare parts,accurate precision detection instrument,which make sure he machine with perfect location and working precision.

# Table:Double-layer compound grade board table design,rugged construction,non-deformation,with functions of instant adsorption and release.

# Tool magazine: With an 8-slots Linear tool changer,tool changes to be performed quickly.

Other type wood cnc router machines for your refence

# Linear or Circular type ATC wood cnc router

# Pneumatic 4 head ATC cnc router

# Wood cnc router with air cooling spindle

# Wood cnc router with water cooling spindle

# Mini cnc router for wood advertising

# Double heads wood cnc router

Our Services

1. 24 hour Technical support by phone, e-mail or MSN around the clock.

2. Friendly English version manual and operation video CD disk.

3.7-15 working days after down payment or full payment.

4. Machine will be adjusted before it is delivered; operation disk/CD was included.

5. Our technician can give you remote guide online (Skype or MSN) if you have any question.

6. Engineers available to service machinery overseas, seller and buyer discuss the charges.

Packaging & Shipping

1) Foam and wrapping film on the surface of the machine inside. Rain-proof, Dust proof.

2)Standard export plywood case. Upwards, moistureproof shipping marks. Safety guaranteed.

3) fumigation-free

4)With shipping mark if you like.

5)Outside: Marked packing size, model, weight and other information.

FAQ

1.How to choose a suitable model ? processing materials? max cutting thickness?

2.Do you have operation manual and working video?

3.Does your company can processing my samples?

4.If I bought machine, but don't know how to operation, what I can do?

5.How am I going to work on service parts on the machine? Example what if parts need to be replaced?

6.Does your engineer do aftersale service at abroad? how much cost?

Company Information

JINAN FIRM CNC EQUIPMENT CO.,LTD

A-505Jingliu Road, Huaiyin District, Jinan City, Shandong Province, China.

Tel: 0086-0531-69986330 Fax : 0086-0531-69986330

Website: http://firmcnc.en.made-in-china.com

firmcnc.en.made-in-china.com

Cell phone: +86-13954117091

Application of oscillating Knife cutting machine

1. It is used for carton,leather,wood,MDF,PVC etc.

2. Userfriendly Machine control interface design High efficiency of the machine help you achieve productivity leap.

3.We use High Quality Spare parts for this machine .Such as Germany cnc oscillating tools and blade 4. Italian HSD Spindle, YASKAWA AC Servo system,German Becker Pump and so on .It is with stable performance.

Technical specification of oscillating Knife cutting machine

| Descriptions | Parameters |

| Modle | FM1325K |

| Working area | 2500*1300*200mm (can be customized) |

| Working Voltage | 380V, 3PHASE, 50HZ (can be customized) |

| Control System | Taiwan SYNTEC control system |

| Control box | 1.4m high control box |

| Oscillating knife | Germany ECOCAM EOT-3 |

| Spindle | 9.0kw air cooling ATC spindle |

| Spindle speed | 0-24000RPM/MIN |

| Tool magazine | Linear type + 8pcs ISO30 tool holders (Carousel type for optional) |

| Motor and Driver | 750w Leadshine hybrid servo motors and drivers |

| Inverter | 5.5kw Fuling inverter |

| Structure | New type thicker and bigger heavy duty welded frame and gantry |

| Table surface | T-slot and Vacuum Working Table |

| Gantry structure | Gantry Moving |

| Lubrication system | Automatic lubrication system |

| Calibration | Automatic tool sensor calibration |

| Mist cooling sprayer | Automaitc oil mist cooling sprayer |

| Transmission | X,Y Axis: Helical rack, Taiwan Hiwin/PMI/ABBA 25# Rail Linear Bearing Z Axis: Taiwan Hiwin/PMI/ABBA Rail 25# Linear Bearing & Taiwan TBI Ball Screw |

| Vacuum pump | 7.5kw water circlulation vacuum pump (220V, 3PHASE, 50HZ) |

| Dust Collector | 1.5kw new type double pockets dust collector (220V, 3PHASE, 50HZ) |

| Command language | G Code |

| Color | According to your reference |

| Applications | Leather, Carpet, Carton, Wood, MDF, PVC, Acrylic, Carboard, Rubber, Corrugated box, Foam, Leather strip. |

Main configuration of oscillating Knife cutting machine

Samples of oscillating Knife cutting machine

Advantage of oscillating Knife cutting machine

# Function: Extremely heavy-duty CNC machining center,suitable for routing,drilling,cutting,edge chamfering,etc.

# Construction: Whole machine table adopts high strength thick steel pipe welded.Whole working table cast by resin sand.

The annealing and other heat treatment methods ensure that the whole structure is tested to the limit for sturdiness and reliability.

# Spare parts: Features world top class mechanical and electronic components,e.g.Taiwan rail and ball screw,French Schneider electrical components,

which guarantee stable performance and high quality.

# Precision: Excellent spare parts,accurate precision detection instrument,which make sure he machine with perfect location and working precision.

# Table:Double-layer compound grade board table design,rugged construction,non-deformation,with functions of instant adsorption and release.

# Tool magazine: With an 8-slots Linear tool changer,tool changes to be performed quickly.

Other type wood cnc router machines for your refence

# Linear or Circular type ATC wood cnc router

# Pneumatic 4 head ATC cnc router

# Wood cnc router with air cooling spindle

# Wood cnc router with water cooling spindle

# Mini cnc router for wood advertising

# Double heads wood cnc router

Our Services

1. 24 hour Technical support by phone, e-mail or MSN around the clock.

2. Friendly English version manual and operation video CD disk.

3.7-15 working days after down payment or full payment.

4. Machine will be adjusted before it is delivered; operation disk/CD was included.

5. Our technician can give you remote guide online (Skype or MSN) if you have any question.

6. Engineers available to service machinery overseas, seller and buyer discuss the charges.

Packaging & Shipping

1) Foam and wrapping film on the surface of the machine inside. Rain-proof, Dust proof.

2)Standard export plywood case. Upwards, moistureproof shipping marks. Safety guaranteed.

3) fumigation-free

4)With shipping mark if you like.

5)Outside: Marked packing size, model, weight and other information.

FAQ

1.How to choose a suitable model ? processing materials? max cutting thickness?

2.Do you have operation manual and working video?

3.Does your company can processing my samples?

4.If I bought machine, but don't know how to operation, what I can do?

5.How am I going to work on service parts on the machine? Example what if parts need to be replaced?

6.Does your engineer do aftersale service at abroad? how much cost?

Company Information

JINAN FIRM CNC EQUIPMENT CO.,LTD

A-505Jingliu Road, Huaiyin District, Jinan City, Shandong Province, China.

Tel: 0086-0531-69986330 Fax : 0086-0531-69986330

Website: http://firmcnc.en.made-in-china.com

firmcnc.en.made-in-china.com

Cell phone: +86-13954117091