Basic Info.

Hardness

52HRC

Surface Treatment

Zinc Coated

Precision Grade

0.001 Um

Transport Package

Hard Paper Box, Pallets

Specification

0.3-----200kgs

Trademark

baiwang

Origin

Zibo

HS Code

8487900000

Production Capacity

50000PCS Year

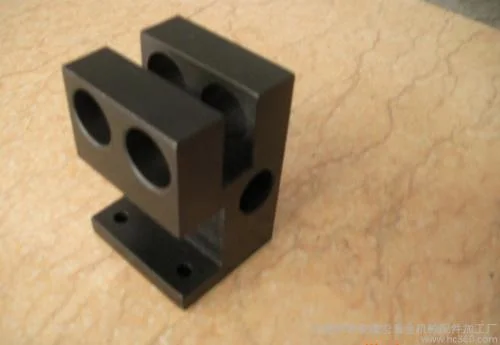

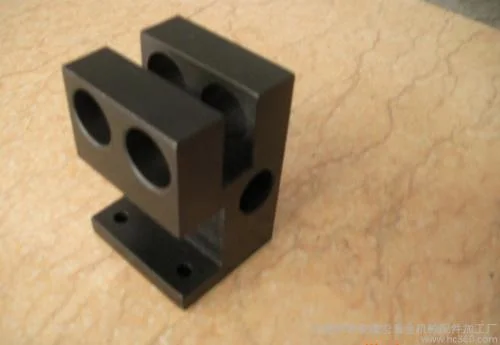

Product Description

We are leading manufacturer and exporter for 10 years inZibo of China about various products with metal material according to client' s design drawings or realsample and prototype.

CNC high precision customized ny turning and milling laser bending stainless steel metal Aluminum,copper machining/machinery machined components parts for cars motor

We can provide CNC machining, turning machine, milling machine, drilling machine, grinding machine, cutting, grinding machine, optical profile griding machine, services, And we also can offer 4 or 5 axis-CNC center processes.

all kinds of auto parts,tractors parts,industrial accessories,pump parts,machines parts,small weihgt and huge weight,

own CNC equipments,quality ensured and lead time quickly,

many kinds of material :stainless steel,alumnimum,gery iron,steel;bronze,copper.....etc;

many kinds of crafts do : quenching hardness,heat treatment,tempering,coated zinc,plated color.....etc;

welcome contact us for detail enquiry.

Our company specializes in precision parts processing, including CNC turning parts, milling parts, sheet metal parts and special materials PG precision grinding. Our equipment includes 3-axis / 4-axis CNC milling machine, CNC turning with driving tool, precision wire cutting machine, grinder, laser cutting machine, bending machine, EDM countersunk head, contour projector, altimeter, hardness tester, etc. Our products are widely used in: medical, power generation, textile, printing, metallurgy, mining, gear transmission, engineering machinery, petrochemical, lifting equipment, etc.

Types of processing: medical device accessories, optical precision accessories, automobile accessories, digital communication products, plant protection machinery accessories, pneumatic tools, automation machinery accessories

Processing range: CNC three axis, four axis processing, CNC milling, CNC turning, CNC lathe high precision five axis turning and milling compound processing

Processing methods: CNC machining, turning, milling, stamping, sheet metal, assembly

Materials: stainless steel, brass, copper, steel, POM, nylon, plastic

Tolerance:CNC Turning/CNC Lathe: +/-0.005 mm

CNC machining /CNC milling: +/- 0.01mm,

Specific products can meet customer requirements

Measuring equipment:Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc.

Package: tissue, environmental protection paper, standard carton or plastic tray, sponge tray, cardboard tray, etc., can be customized according to customer requirements

Our advantages:

1) 20 years of working experience in precision CNC machining industry

2) Advanced production and testing equipment

3) Strictly implement international quality standards and management systems

4) Mature supply chain creates value for customers

5) Fast delivery and reasonable price

6) Accept small orders

7) The highest quality is guaranteed by skilled workers, management system and facility conditions

8) 100% delivery quality inspection

9) Provide professional advice to customers in the design process to save costs.

Surface treatment: Polishing, zinc plating, nickel plating, chrome plating, powder coating, e-coating, DIP coating, phosphate coating, anodize, dichromate plating, decrement plating, etc.

Advance equipment: CNC lathes, auto-lathes, punching equipment and many other auxiliary equipment like drilling tapping, polishing, and grinding machines.

We also can do heat treatment hardness from 32HRC----65HRC according to customers drawings requirements.

Quality control instruments: Digital projector, Rockwell hardness tester, height gauge, digital micrometer, microscope, hydraulic pressure testing bench, various calipers, thread ring, and plug gauges

Our products main use in metal and alumninum, electronic appliances, medical instrument, telecommunications, automobile, machinery,tractors parts,lathe parts,

CNC high precision customized ny turning and milling laser bending stainless steel metal Aluminum,copper machining/machinery machined components parts for cars motor

We can provide CNC machining, turning machine, milling machine, drilling machine, grinding machine, cutting, grinding machine, optical profile griding machine, services, And we also can offer 4 or 5 axis-CNC center processes.

all kinds of auto parts,tractors parts,industrial accessories,pump parts,machines parts,small weihgt and huge weight,

own CNC equipments,quality ensured and lead time quickly,

many kinds of material :stainless steel,alumnimum,gery iron,steel;bronze,copper.....etc;

many kinds of crafts do : quenching hardness,heat treatment,tempering,coated zinc,plated color.....etc;

welcome contact us for detail enquiry.

Our company specializes in precision parts processing, including CNC turning parts, milling parts, sheet metal parts and special materials PG precision grinding. Our equipment includes 3-axis / 4-axis CNC milling machine, CNC turning with driving tool, precision wire cutting machine, grinder, laser cutting machine, bending machine, EDM countersunk head, contour projector, altimeter, hardness tester, etc. Our products are widely used in: medical, power generation, textile, printing, metallurgy, mining, gear transmission, engineering machinery, petrochemical, lifting equipment, etc.

Types of processing: medical device accessories, optical precision accessories, automobile accessories, digital communication products, plant protection machinery accessories, pneumatic tools, automation machinery accessories

Processing range: CNC three axis, four axis processing, CNC milling, CNC turning, CNC lathe high precision five axis turning and milling compound processing

Processing methods: CNC machining, turning, milling, stamping, sheet metal, assembly

Materials: stainless steel, brass, copper, steel, POM, nylon, plastic

Tolerance:CNC Turning/CNC Lathe: +/-0.005 mm

CNC machining /CNC milling: +/- 0.01mm,

Specific products can meet customer requirements

Measuring equipment:Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc.

Package: tissue, environmental protection paper, standard carton or plastic tray, sponge tray, cardboard tray, etc., can be customized according to customer requirements

Our advantages:

1) 20 years of working experience in precision CNC machining industry

2) Advanced production and testing equipment

3) Strictly implement international quality standards and management systems

4) Mature supply chain creates value for customers

5) Fast delivery and reasonable price

6) Accept small orders

7) The highest quality is guaranteed by skilled workers, management system and facility conditions

8) 100% delivery quality inspection

9) Provide professional advice to customers in the design process to save costs.

Surface treatment: Polishing, zinc plating, nickel plating, chrome plating, powder coating, e-coating, DIP coating, phosphate coating, anodize, dichromate plating, decrement plating, etc.

Advance equipment: CNC lathes, auto-lathes, punching equipment and many other auxiliary equipment like drilling tapping, polishing, and grinding machines.

We also can do heat treatment hardness from 32HRC----65HRC according to customers drawings requirements.

Quality control instruments: Digital projector, Rockwell hardness tester, height gauge, digital micrometer, microscope, hydraulic pressure testing bench, various calipers, thread ring, and plug gauges

Our products main use in metal and alumninum, electronic appliances, medical instrument, telecommunications, automobile, machinery,tractors parts,lathe parts,