- Overview

- Product Description

- Machine details

- Sample

- FAQ

- Contact us

Basic Info.

Model NO.

3015R Fiber Laser Cutting Machine

Cooling System

Water Cooling

Technical Class

Continuous Wave Laser

Applicable Material

Metal

Structure Type

Gantry Type

Laser Classification

Solid Laser

Laser Technology

Laser Control Fault Cutting

Working Area

3000*1500mm

Bed Structure

High Rigidity Welded Steel Framework

Table Surface

Blade Table with Water Cooling

Laser Source

Raycus

Laser Cutting Head

Raytools

Guide Rail

Taiwan Hiwin Square Linear Guide Rail

Transmission

X, Y with Helical Gear Rack, Z with Tbi Ball Screw

Control System

Fscut Control System

Transport Package

One Plywood Case with Water-Proof Materials

Specification

20ft container

Trademark

LOOKE

Origin

Shandong, China

HS Code

8465990000

Production Capacity

500sets/Month

Packaging & Delivery

Package Size

457.00cm * 225.00cm * 208.00cm

Package Gross Weight

1750.000kg

Product Description

cnc laser cutting machine brass iron carbon stainless steel cutter machine fiber laser cutting

Main Features Fiber laser power source options from 1000W to 3000W. Light alloy beam (Y axis) to provide High dynamic performance. The optical path changes while the sheet remains still, thus the processing efficiency is high.

X, Y axis adopts high quality gear and rack, reduction gear, ensuring life and precision for a long time.

Imported Servo Motors. All motors are with Absolute Encoder.

The system is equipped with section dust collector to improve the working environment. The area beneath the cutting table is divided into several sections. During the cutting process, only the ducts directly beneath the cutting head are open for fume extraction. The ducts in the other sections remain closed to improve dust collection.

Applications for cutting stainless steel, carbon steel, aluminum, titanium, and most non-ferrous metals.

| Model | LOOKE-L3015F 4 Axis Fiber laser cutting machine |

| Working area | 1500*3000mm working area |

| Laser source | 1000/1500/2000/3000W Raycus/ MAX fiber laser source |

| Laser cutting head | Raytools or WSX laser head |

| Bed structure | High rigidity welded steel framework |

| Table surface | Blade table |

| Guide rail | Taiwan Hiwin linear square guide rail 25mm |

| Transmission | X,Y with helical gear rack ,Z with TBI ball screw |

| Motors and drivers | FUJI servo motor & driver, X,Y axis 750w, Z axis 400w |

| Control system | FSCUT 3000S control system |

| Software | TubePro CypCut software |

| Chiller | S&A, Dual Temperature Control or Hanli brand chiller |

| Tube size | Length: 6m Diameter: 200/350mm |

| Reducer | Japan imported SHIMPO reducer |

| Tool sensor | Automatic tool sensor |

| Lubrication system | Electric automatic lubrication system |

| Pressure valves | High-pressure(N2,air):2.5MPa(Shuoda) Low-pressure(O2):1MPa(SMC) |

| Electronic Proportional Valve | SMC from Japan |

| Electronic Components | SCHNERDER, Omron |

| Max. idling speed | 80m/min |

| Positioning Accuracy | ±0.03mm |

| Re-Positioning Accuracy | ±0.02mm |

| Instruction format | G code *.u00 *.mmg *.plt |

| Working voltage | AC380V, 3 phase,50-60hz(for more than 1000w) AC220V, single phase, 50-60hz(for 1000w) |

| Others | Tool box, English Manual, Exhaust fan, cutting nozzle, protection mirrors etc |

Industrial Machine Bed

| The bed is welded by high-strength steel plates, which has a higher intensity than the welded square tube. The semi-hollow bed design is adopted, and the heating area is small to avoid bed deformation due to long-term high temperatures. It effectively guarantees the realization of long-term batch and stable cutting for users. |

Gantry

| Welded by high-strength manganese steel, the overall beam adopts high rigidity and a large cross-section structure. Aging treatment ensures its high level of rigidity, strength, stability, and impact resistance. High-quality materials are se-lected, molded after finite element analysis and optimization, and undergo annealing, rough machining, vibration aging, fin-ishing, and other processes. Use Taiwan brand HIWIN H glass guide and slide for the x-axis, with YYC Helical rack give machine high accuracy. Z-axis use ball screw transmission give more higher precision. |

Laser Cutting Head

| Working Principle The laser beam will be focused by the focusing lens in the cutting head and then acts on the surface of the processed material to vaporize the cutting material and complete the cutting with the help of auxiliary gas. |

| Nozzle It prevents melting stains and other sundries from bouncing up and contaminating the focusing lens and decides the size of gas diffusion. Its service life is about 600 hours. |

| Protective Lens It is a lens that prevents dust and slag splashing from damaging the focusing lens and collimating the lens inside of the laser head and is an essential accessory for laser cutting ma-chines. |

Control System

| Multiple functions | Easy operation | Automatic optimization |

| It simplifies complex CNC machine operation and integrates CAD, Nest and CAM modules. Drawing, nesting and workpiece cutting all can be finished by a few clicks. | Graphical design of technique setting enables users to quickly and easily to finish setting of lead line, micro-joint and kerf width compensation etc. of single or large quantity parts. | CypCut will automatically optimize the errors when import drawing, delete duplicates and invisible graphic, smooth curve and join line segments etc. Auto correct the dual-drive position error each time after machine axes return origin. |

Other Accessories

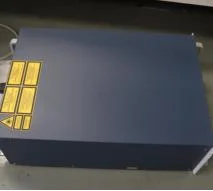

| 1.Raycus Laser source The new fiber laser 1500w has higher electro-optical conversion efficiency, higher and more stable optical quality, stronger altitude stress-resisting capacity and they apply optimized second-generation fiber transmission system to ensure more stable and more sophisticated cutting effect in thick sheet cutting. |

| 2.FUJI servo drive

|  |

| 3.S&A water Chiller

|

| 4.Control cabinet

|  |

| 5.Auxiliary feeding wheel

|

| 6.Guide rail

|  |

| 7.Gear Rack

|

| 8.Lubrication system

|  |

Q1: I know nothing about this machine, what type of machine should I choose?

Q2: When I got this machine, but I don't know how to use it. What should I do?

We will send English manual and Operation Video and for the machine. Our engineer will do training online. If needed, we can send our engineer to your site for training or you can send the operator to our factory for training.

Q3: May we know the speed of your Fiber Laser Cutting Machine as per on our demand basis?

We use Japan Servo motor and driver with big strength, so the max moving speed can reach 120m/min, max cutting speed can reach 40m/min. And the speed can reach 1.5-2m/min if you cut 4.5-5mm stainless steel.

Q4: If some problems happen to this machine, what should I do?

We provide two years machine warranty. During the two-year warranty, in case any problem for the machine, we will provide the parts free of charge (except for artificial damage). After the warranty, we still provide whole lifetime service. So any doubts, just let us know, we will give you solutions.

Q5: About accuracy, we have observed that after some time "Machine accuracy can increase gradually" and after long time, the difference reach to its maximum level. How about your machine?

The frame of the machine is annealed, it can support shock resistance(the machine will deform if without annealing ). So the accuracy of the machine can keep its original accuracy for 4-5 years. The weight of the machine can reach 4.5t-5.0t. It also can let the machine have higher accuracy and higher stability.

We will help you choose the suitable machine and share you the solution; you can share us what material will you cut, the material

thickness and working size.

thickness and working size.

Q2: When I got this machine, but I don't know how to use it. What should I do?

We will send English manual and Operation Video and for the machine. Our engineer will do training online. If needed, we can send our engineer to your site for training or you can send the operator to our factory for training.

Q3: May we know the speed of your Fiber Laser Cutting Machine as per on our demand basis?

We use Japan Servo motor and driver with big strength, so the max moving speed can reach 120m/min, max cutting speed can reach 40m/min. And the speed can reach 1.5-2m/min if you cut 4.5-5mm stainless steel.

Q4: If some problems happen to this machine, what should I do?

We provide two years machine warranty. During the two-year warranty, in case any problem for the machine, we will provide the parts free of charge (except for artificial damage). After the warranty, we still provide whole lifetime service. So any doubts, just let us know, we will give you solutions.

Q5: About accuracy, we have observed that after some time "Machine accuracy can increase gradually" and after long time, the difference reach to its maximum level. How about your machine?

The frame of the machine is annealed, it can support shock resistance(the machine will deform if without annealing ). So the accuracy of the machine can keep its original accuracy for 4-5 years. The weight of the machine can reach 4.5t-5.0t. It also can let the machine have higher accuracy and higher stability.

Very sincerely look forward to your inquiry!

Any questions about our products,welcome to contact me!

Contact: Hannah Hou Mob: +86 132 0540 9528

WhatsApp:+86 132 0540 9528

Any questions about our products,welcome to contact me!

Contact: Hannah Hou Mob: +86 132 0540 9528

WhatsApp:+86 132 0540 9528