- Overview

- Product Description

- Functions

- Product Advantages

- Application

- Product Parameters

- Detailed Photos

- Sample

- Company Profile

Basic Info.

Model NO.

Smart Pro+

Structure Type

Gantry Type

Laser Classification

Raycus Fiber

Laser Technology

Laser Control Fault Cutting

Transmission System

Dual Sides Driven Gantry Structure

CNC System

Fscut 1000

Servo Motor

FUJI(Japan)

Laser Cutting Head

Raytools

Lubrication System

Full-Automatic

Appearance Size

4550mm×2280mm×2100mm

Transport Package

Wood

Specification

no more than 3000 Kg

Trademark

HGTECH

Origin

Wuhan, Hubei. China

Production Capacity

500sets/Month

Product Description

SMART PRO SERIES Laser Cutting Machines

Overview

The machine adopts self-developed fiber laser, which has strong cutting ability and efficiency. It is a high-end and high-tech fiber laser cutting machine integrating advanced technologies such as laser cutting, precision machinery and numerical control technology.

| MODEL | SMART 3015 Pro | SMART 4015 Pro | SMART 4020 Pro | SMART 6015 Pro |

| Cutting Area (L×W) | 3048mm x 1524mm | 4064mm x 1524mm | 4064mm x 2032mm | 6096mm x 1524mm |

| Laser Source | Fiber & 1000W - 6000W | |||

| CNC System | FSCUT | |||

| Max Moving Speed | 120m/min, Acceleration is 1.2G | |||

| Position Accuracy (X and Y axis) | 0.05mm | |||

| Reposition Accuracy (X and Y axis) | 0.03mm | |||

| Power Supply Requirement | 380V 50/60Hz | |||

The Smart3015 series CNC fiber laser cutting machine is a product manufactured by South China University of Technology Xingdong Technology according to international export standards. This series of products is the first choice for the metal material processing industry, with strong cutting ability, flying cutting speed, ultra-high stability, high-quality processing, extremely low operating cost and ultra-high adaptability.

The machine adopts gantry double-drive structure, which has the characteristics of stable structure, good rigidity and high speed. Its X and Y single-axis positioning speed can reach more than 100m/min, and the double-drive acceleration makes the maximum acceleration of X and Y single-axis reach 1.0G.

Excellent function

Vibration Suppression

One key quick setting can easily solve the vibration problem of thick plate processing

One key quick setting can easily solve the vibration problem of thick plate processing

Intelligent obstacle avoidance

Intelligently avoid random raised areas in the cutting process and reduce the risk of head collision

Exclusive tuning database

All you need to do is a simple touch,

and the complicated operations are handed over to us

and the complicated operations are handed over to us

Three point edge finding

The inclination angle and origin of sheet metal are sensed through automatic edge-finding to avoid waste and save time

Advantages:

1.As a whole welded structure, the bed has been aging for many times, which has the advantage of good dynamic response;2.The transmission is equipped with high-precision and high-efficiency transmission mechanism, which has good rigidity and high precision and 3.ensures the long-term high-precision operation of the equipment;

3.It has strong cutting ability and efficiency, and integrates advanced technologies such as laser cutting, precision machinery and numerical control technology.

4.Safer and more environmentally friendly.

Application

HGlaser fiber laser cutting machine for sale is an affordable, easy-to-use, and versatile tool that can help you begin a new start-up venture or increase the profits of your well-established company. This type of fiber laser cutter is suitable for cutting stainless steel, carbon steel, alloy steel, spring steel, copper plate, aluminum plate, gold, silver, titanium ect., and has been widely used in advertising, high pressure / low voltage electrical cabinet production, textile machinery accessories, kitchen appliances, cars, machinery, elevators, electrical accessories, spring coil pieces, metro line parts and other industries.Technical Specification

| Machine Model | SMART3015 Pro-1000 |

| Cutting Area (L×W) | 3048mm×1524mm |

| Laser Source | Raycus Fiber & 1000W |

| Transmission system | Dual sides driven gantry structure |

| CNC System | FSCUT 1000 |

| Servo Motor | Fuji(JAPAN) |

| Laser Cutting Head | Raytools |

| Display | 21" Industry LCD |

| Max Moving Speed | 120m/min, Acceleration is 1.2G |

| Position Accuracy (X and Y axis) | 0.05mm |

| Reposition Accuracy (X and Y axis) | 0.03mm |

| Lubrication system | Full-automatic |

| Power Supply Requirement | 380V 50/60Hz |

| Max loading (KG) | 900 KG |

| Machine weight | ≤3000 Kg |

| Appearance size | 4550mm×2280mm×2100mm |

| Working environment | Temp:0- 40 ºC,humidity:≤80% |

Machine bed

Beam

Laser source

Applicable to cutting carbon steel, stainless steel, aluminum, brass , alloy metals, etc.

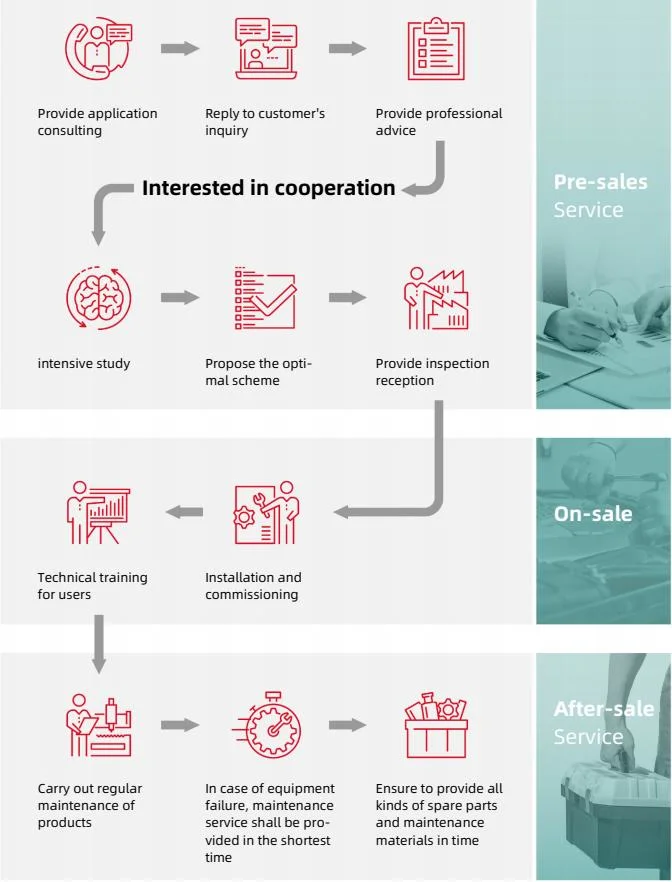

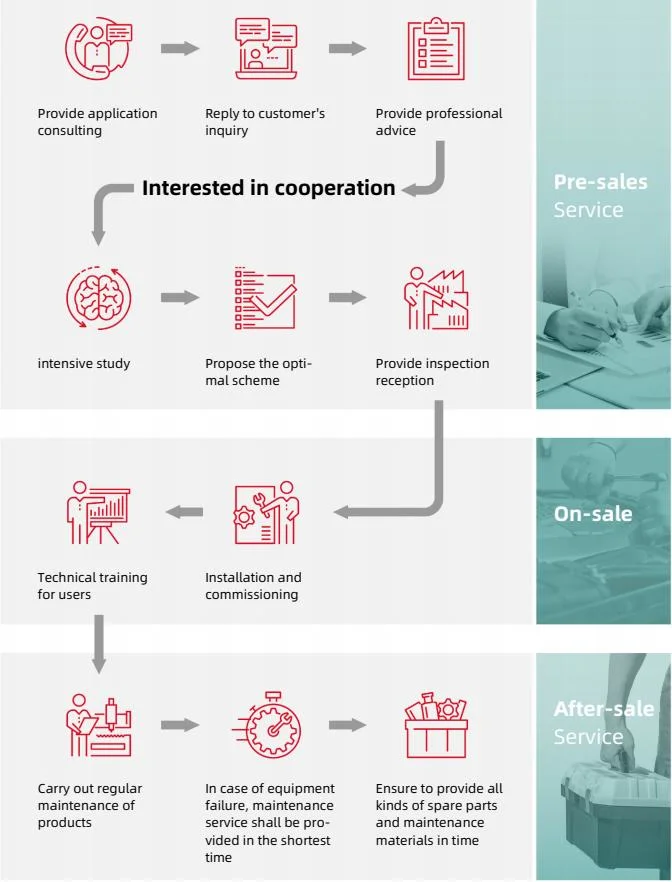

After-sale Service

1. Warranty period: From the acceptance qualified date, the warranty period will be 1 (one) year, but in any case, not more than 13 months after B/L date. Seller is responsible to offer free fittings in these years (except consumable part.) Buyer has to send the damaged fitting to sellers. After the warranty, we will also provide favorable service of long term technical supports and spares supply to ensure machine's stable and continuous running.

2. The artificial damage in the warranty period and damage after warranty period, Seller offers paid service.

3. The Seller will give 24 hours service support during warranty time, and giving technical guide by email, telephone, Fax for daily maintenance, if need local support, Buyer has to pay for the travel and

accommodation & meal cost for the people from seller's side, no labor charge require. If products are out of warranty and require on site service, Buyer have to pay for the travel and accommodation & meal cost for the people from seller's side, labor charge is require, USD200/day per people.

4. About the transportation expanses of spare parts will be supported by both parties in the warranty period, like Buyer support the cost of transportation for damage spare part back to supplier; Seller support the new spare part deliver to Buyer.

2. The artificial damage in the warranty period and damage after warranty period, Seller offers paid service.

3. The Seller will give 24 hours service support during warranty time, and giving technical guide by email, telephone, Fax for daily maintenance, if need local support, Buyer has to pay for the travel and

accommodation & meal cost for the people from seller's side, no labor charge require. If products are out of warranty and require on site service, Buyer have to pay for the travel and accommodation & meal cost for the people from seller's side, labor charge is require, USD200/day per people.

4. About the transportation expanses of spare parts will be supported by both parties in the warranty period, like Buyer support the cost of transportation for damage spare part back to supplier; Seller support the new spare part deliver to Buyer.

Service Process

Packaging and shipping

Packaging and shipping

About Us

Hgstar is the member of HGTECH Group.

HGTECH has always been committed to providing broad and comprehensive laser manufacturing solutions in industrial manufacturing field.

In 2021, HGSTAR was established. Our main products are laser cutting machines, laser welding machines, laser cleaning machines and smart series focusing on the needs of 1000w-6000w laser cutter users.

Relying on HGTECH's 50 years of R & D and production experience in the laser industry, perfect global after-sales system and the advantages of combining online and offline overseas after-sales service points, we provide you with better quality and more economical choice.

In 2021, HGSTAR was established. Our main products are laser cutting machines, laser welding machines, laser cleaning machines and smart series focusing on the needs of 1000w-6000w laser cutter users.

Relying on HGTECH's 50 years of R & D and production experience in the laser industry, perfect global after-sales system and the advantages of combining online and offline overseas after-sales service points, we provide you with better quality and more economical choice.

Company certification

Our Vision:

Participate in building a fully connected,

fully perceptual, and intelligent world,

and become a global influential tech-

nology company

Business Partners:

FAQ:

Q: What's the package?

A: We have 3 layers package. For the outside, we adopt wood craft case. In the middle, the machine is covered by foam, to protect the machine from shaking. For the inside layer, the machine is covered by thickening plastic bag for waterproof.

Q: Will the package damaged during transportation?

A: Our package is considerate all the damage factors and make it to be safe, and our shipping agent have full experienced in safe transportation. We have exported to 180 countries worldwide. So please don't worry, you will receive the parcel in good condition.

Q: How to install and run the machine?

A: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training video, user's manual along with the machine. 95% customers can learn by themselves.

Q: How can I do if the machine goes wrong?

A: If confronted with such problems, please contact us asap and do not try fix the machine by yourself or someone else. We will response within 24 hours as quick as we can to solve it for you.

Please advise us the following information, then we can recommend you the most suitable model, right now, don't hesitate to contact -China HG STAR!

Q: What's the package?

A: We have 3 layers package. For the outside, we adopt wood craft case. In the middle, the machine is covered by foam, to protect the machine from shaking. For the inside layer, the machine is covered by thickening plastic bag for waterproof.

Q: Will the package damaged during transportation?

A: Our package is considerate all the damage factors and make it to be safe, and our shipping agent have full experienced in safe transportation. We have exported to 180 countries worldwide. So please don't worry, you will receive the parcel in good condition.

Q: How to install and run the machine?

A: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training video, user's manual along with the machine. 95% customers can learn by themselves.

Q: How can I do if the machine goes wrong?

A: If confronted with such problems, please contact us asap and do not try fix the machine by yourself or someone else. We will response within 24 hours as quick as we can to solve it for you.

Please advise us the following information, then we can recommend you the most suitable model, right now, don't hesitate to contact -China HG STAR!