Basic Info.

Model NO.

PFT080

Brand Name

Perfect

Place of Origin

Jiangsu, China (Mainland)

Raw Material

High Speed Steel

Coating

Tin-Coated/Bright Finishing

End Mill Type

4/6/8 Flute Flat

Shank

Parallel Shank

Service

OEM/ODM

Usage

PCB CNC Machine

Transport Package

1PS/ Plastic Box

Specification

6-40mm

Trademark

Perfect

Origin

Jiangsu China

HS Code

8207709000

Production Capacity

10000PCS/Month

Product Description

Description:

These long foam router bits are the flat end mill cutters for foam milling and cutting, specifically designed for milling Polyurethane Foam, Polyethylene Foam, Extruded Polystyrene Foam (XPS), Expanded Polystyrene (EPS) and Ethylene Vinyl Acetate (EVA), insulation foam and similar types of foams to ensure your foam projects are milled with unparalleled accuracy, detail and clarity.

These long foam endmills allow you to achieve both precision and depth for foam cutting and milling applications, also great for roughing process. Longer foam cutting bits come deeper cuts and thicker slices with fewer passes, improved productivity and reduce assembly.

Flat End Extra-Long Foam Router Bits Features:

1, High Speed Steel (HSS) hardness: HRC 61-64.5°

2, Sharp spiral flute for clear smooth finishing

3, Extra-long reach 2D and 3D CNC Cutting & Milling

4, Flat end or square bottomed design, also can do drilling job

5, Foam cutter size could be customized

6.Applicable materials: plastic, foam, soft polyurethane. EVA material holding,

Field of application: EPS styrofoam foam die-casting molds, stamping dies, machine parts or art parts, reusable models, plastic molding models, model samples, packages

7.Main features: sharp edge, good surface finish for side milling, multi-blade cutting design for smoother cutting, longer lengths for deeper cuts,

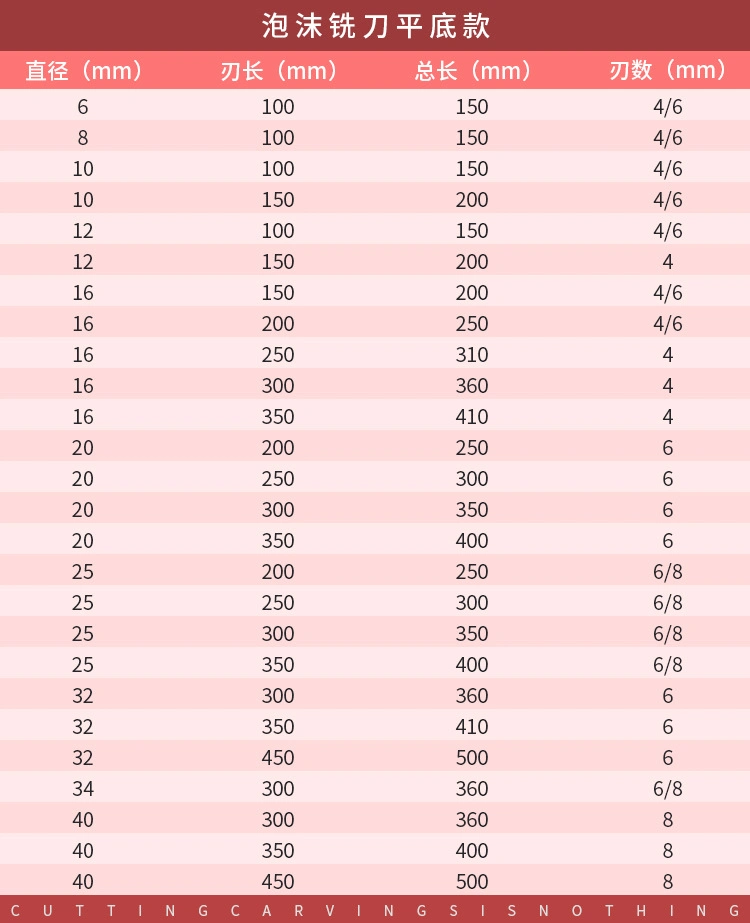

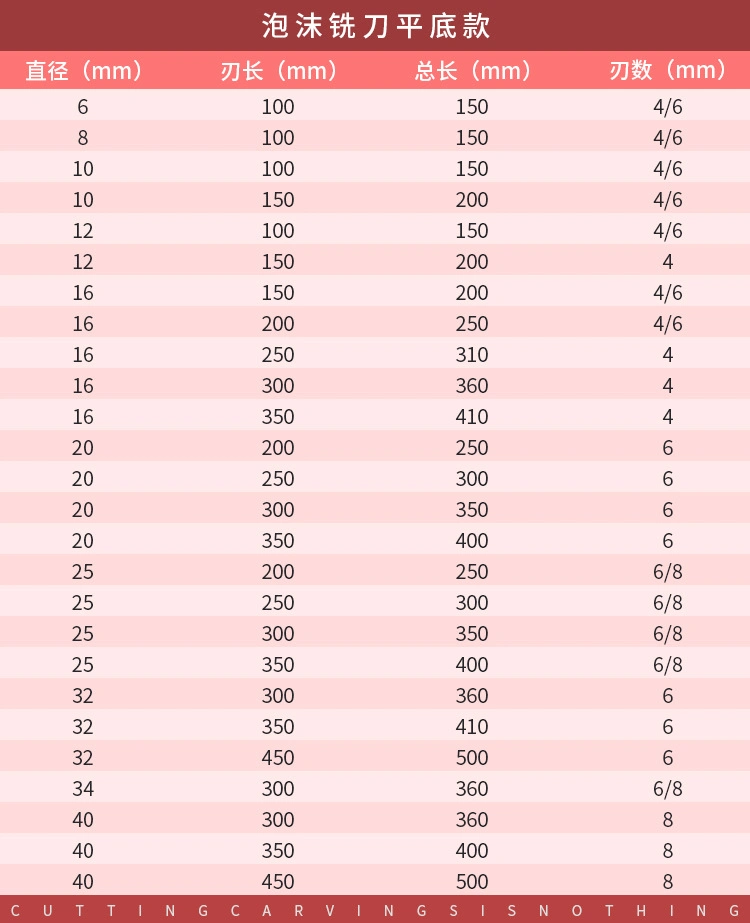

Size:

Recommend parameters for foam milling:

The long bits for foam cutting, we usually recommend run at 6000-7000rpm. It is good to the machine cutters and can get good surface finish.

Feeding speed at 5000-6000mm/min.

For bigger and longer bits, suggest start from 3000rpm, and adjust. The tool not vibrates much and not make much noise is ok.

You can adjust it from slow speed.

These parameters just for reference, you can adjust as per your machine's rigid, foam density, cutting depth, etc. Just test from slow speed to avoid tool broken.

Ball nose, conical tapered bits, and flat square end mill foam mills are available, also we can make big long solid carbide router bits for wood mould milling.

Perfect CNC foam mill bits are widely worked with KUKA, YASKAWA robotics, SprutCAM Robot, gantry 5 axis machining centers, big foam-cutting gantry routers, and get great feedback and more orders from our clients.

We supply a range of durable router bits made specifically for milling EPS, EVA and polyurethane foam, including regular and tapered cutters in ball end and end mill styles. Ball Nose, Flat Bottom (End Mill), conical styles are available.

These long foam router bits are the flat end mill cutters for foam milling and cutting, specifically designed for milling Polyurethane Foam, Polyethylene Foam, Extruded Polystyrene Foam (XPS), Expanded Polystyrene (EPS) and Ethylene Vinyl Acetate (EVA), insulation foam and similar types of foams to ensure your foam projects are milled with unparalleled accuracy, detail and clarity.

These long foam endmills allow you to achieve both precision and depth for foam cutting and milling applications, also great for roughing process. Longer foam cutting bits come deeper cuts and thicker slices with fewer passes, improved productivity and reduce assembly.

Flat End Extra-Long Foam Router Bits Features:

1, High Speed Steel (HSS) hardness: HRC 61-64.5°

2, Sharp spiral flute for clear smooth finishing

3, Extra-long reach 2D and 3D CNC Cutting & Milling

4, Flat end or square bottomed design, also can do drilling job

5, Foam cutter size could be customized

6.Applicable materials: plastic, foam, soft polyurethane. EVA material holding,

Field of application: EPS styrofoam foam die-casting molds, stamping dies, machine parts or art parts, reusable models, plastic molding models, model samples, packages

7.Main features: sharp edge, good surface finish for side milling, multi-blade cutting design for smoother cutting, longer lengths for deeper cuts,

Size:

Recommend parameters for foam milling:

The long bits for foam cutting, we usually recommend run at 6000-7000rpm. It is good to the machine cutters and can get good surface finish.

Feeding speed at 5000-6000mm/min.

For bigger and longer bits, suggest start from 3000rpm, and adjust. The tool not vibrates much and not make much noise is ok.

You can adjust it from slow speed.

These parameters just for reference, you can adjust as per your machine's rigid, foam density, cutting depth, etc. Just test from slow speed to avoid tool broken.

Ball nose, conical tapered bits, and flat square end mill foam mills are available, also we can make big long solid carbide router bits for wood mould milling.

Perfect CNC foam mill bits are widely worked with KUKA, YASKAWA robotics, SprutCAM Robot, gantry 5 axis machining centers, big foam-cutting gantry routers, and get great feedback and more orders from our clients.

We supply a range of durable router bits made specifically for milling EPS, EVA and polyurethane foam, including regular and tapered cutters in ball end and end mill styles. Ball Nose, Flat Bottom (End Mill), conical styles are available.