- Overview

- Product Description

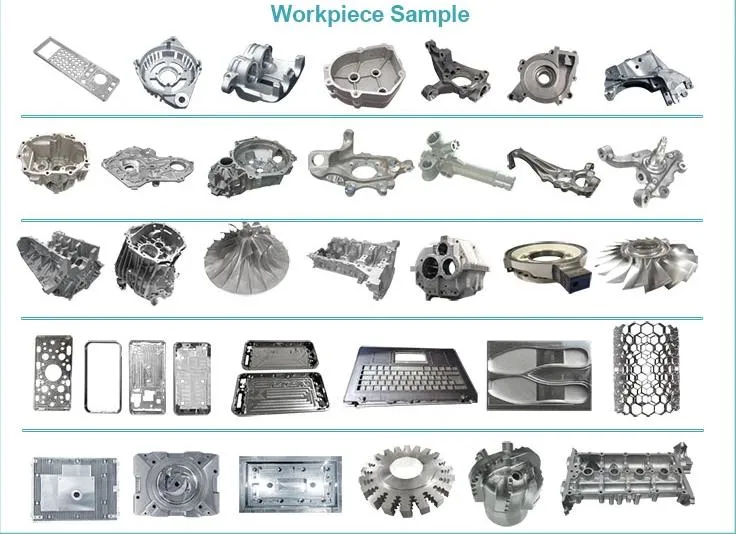

- Detailed Photos

- Company Profile

- Product Parameters

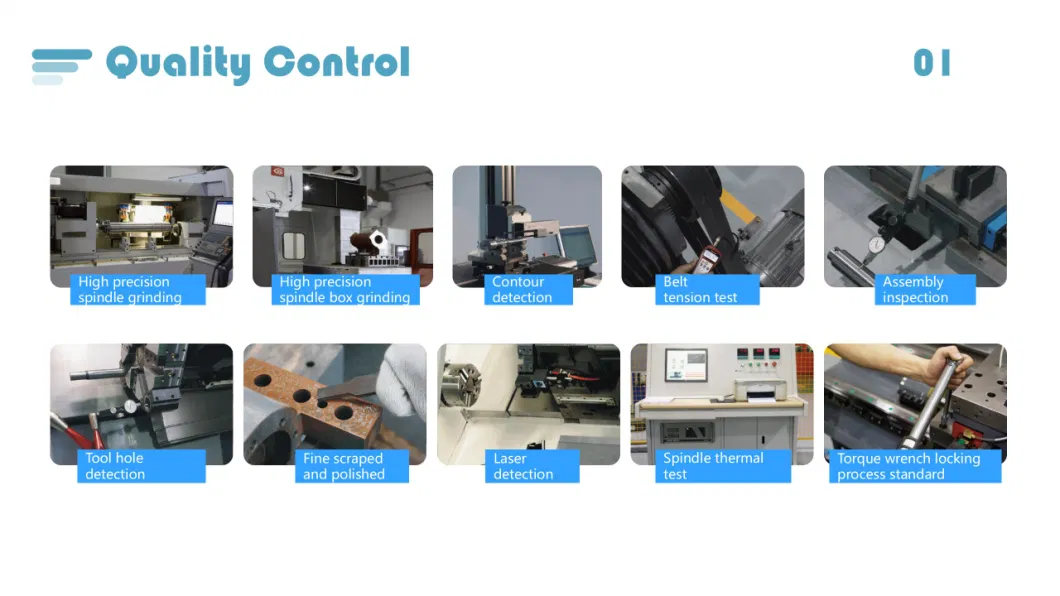

- Quality Control

- Certifications

- Packaging & Shipping

Basic Info.

Packaging & Delivery

Product Description

HMC63 is the company's own design and manufacture of the leading products, the use of international popular inverted T-type movable column overall bed structure, the whole machine structure, reasonable layout, with sufficient strength, rigidity and stability, good Maintenance Technology. Through repeated experiments, the machine tool has good dynamic performance, motion accuracy control, accuracy, processing accuracy stability and good retention, and can complete contour milling and plane milling in one clamping, can carry out four-face milling, drilling, reaming, boring, reaming, tapping and other processes. Most suitable for medium, small batch, multi-variety box parts and complex shape of the surface, processing, saving tooling, shorten production cycle, improve processing accuracy. Widely used in machinery, electronics sector of all walks of life, is the modernization of national defense industry, automobile manufacturing, tractors, molds, light industry machinery and machine tool industry technical transformation, equipment replacement necessary products.

We also have other model, such as HMC-50, HMC-80, HMC-100, HMC-100M, HMC-LW855.

We are Jiangsu Zechuan Industrial Intelligent Equipment Co. Ltd. It is a high-tech enterprise engaged in the CNC machine tool application research and development, production, sales, installation and after-sale service for many years.

We are doing domestic general commercial trade and import and export trade. Our main productions are: vertical processing center, gantry processing center, horizontal processing center, CNC tilted lathe and other series. It can also customize special machines according to customers' need.

Our customers are covering hardware, mold, communication, IT industry, medical equipment, aerospace, auto parts and other industries.

Our main partners are:

- BEIJING ZHICHUANG UNITED TECHNOLOGY CO., LTD. has the relevant qualification issued by the State Administration of Science, Technology and Industry for National Defense and is an equipment contractor issued by the General Equipment Department. It is engaged in the R&D and production of hot-forming titanium alloy components and hot-forming superalloy components

- Jiangsu Shangqi Group, a forklift maker, the supplier of KION Baoli (Jiangsu) Forklift Co., Ltd, a member of KION Group in Germany

- Weichai Holding Group Co., Ltd. produces engines, new energy motor components

- Suzhou Inovance Technology Co., Ltd. is engaged in industrial control, motor manufacturing, industrial robot manufacturing and application

- Zhejiang Geely Holding Group is engaged in the research and development of auto parts, manufacturing, among which the new energy motor is also produced there

- WUXI YINGFENG AUTO PARTS MANUFACTURING CO., Ltd. is engaged in the application of automotive engine, transmission, automotive diesel pump, vibration damping system, and engaged in aluminum alloy parts for motor, engine, high-speed locomotive motor industry, etc

There are so many other partners, I will not list them all.

We hope you are our next and forever partner.

Why Choose Zechuan machine

1) Excellent quality, competitive price, prompt delivery, on-time service and good reputation.

2) Fast sample delivery

3) Low minimum order

4) Fast shipment in 15~20 days on receipt of your payment.

5) We handle all the components needed for utility-connected systems, or for powering independent homes and remote industrial sites.

6) We offer knowledgeable tech support before and after the sale.

The machine tool has the functions of drilling, boring, milling, expanding, reaming, rigid tapping, linear interpolation, arc interpolation, spiral interpolation, three-coordinate linkage, etc. Mainly carry out numerical control processing of various basic large parts, plate parts, disc parts, shell parts, molds and other precision parts. It is suitable for aerospace, shipbuilding, power generation, industry, heavy machinery, locomotives, machine tools, textile machinery, printing machinery, mold manufacturing and other industries.

The fixed beam type gantry frame structure is adopted, the bed is fixed, and the double columns are bolted to the two sides of the bed. The worktable moves on the X axis on the bed, the spindle box moves in the Z direction on the saddle, and the slide saddle and the spindle box move in the Y direction on the beam.

The main large parts of the machine tool: bed, worktable, column, beam, saddle, and headstock are all made of high-strength cast iron and resin sand. These large parts are optimized by three-dimensional computer software. The layout of the ribs is reasonable and has perfect The heat treatment process is used to eliminate residual stress and ensure that the whole machine has sufficient strength, rigidity and high stability.

OUR CUSTOM SERVICE

1.Our company will be responsible for the 12-month free warranty service for the machine tools and accessories purchased in this project. The warranty period shall be calculated from the day when the representatives of both parties sign the equipment acceptance form.

2.Out of warranty: Lifetime service. After the warranty period, our company will provide free technical assistance, and provide customers with paid maintenance services, including fault repair and replacement of original parts. Costs will be charged for parts replacement, and related labor costs. This will be negotiated by both parties as appropriate.

3.Our company provides video guidance for equipment installation. If the customer needs our company to arrange testing staff, the travel expenses will be borne by the customer.

| ITEM | UNIT | HMC63 | |

| Work range | X-axis travel | mm | 1050 |

| Y-axis travel | mm | 750 | |

| Z-axis travel | mm | 900 | |

| Spindle nose to table center distance | mm | 130-1030 | |

| Spindle center to table face distance | mm | 120-870 | |

| Spindle | Spindle Max Speed | rpm | 6000 |

| Spindle taper | BT50 | ||

| Spindle motor power | KW | 15/18.5 | |

| Spindle motor torque | Nm | 191 | |

| Worktable | Worktable size | mm | 630*700 |

| Max.loading | kg | 1000 | |

| T slot size | 5-22-125 | ||

| Dividing precision degree | '' | 10 | |

| Repeat precision degree | '' | 5 | |

| Magazine tool | Capacity magazine | PCS. | 24 |

| Feed | X/Y/Z rapid moving | m/min | 24/24/24 |

| Feeding speed | m/min | 10 | |

| Accuracy | Position accuracy | mm | 0.010 |

| Re-position accuracy | mm | 0.006 | |

| Others | Machine net weight | kg | 13500 |

| Dimensions | mm | 4500×3200×3000 | |

Payment Term

| Payment Terms | T/T | EXW | 30% T/T in advance, the balance to be paid before dispatch |

| FOB | |||

| CIF | 30% T/T in advance, the balance to be paid against the copy of B/L | ||

| CFR (C&F) | |||

| L/C | Irrevocable L/C at sight could be accepted if amount above US $50,000.00 | ||

| Delivery Time | 7 to 10 working days after receiving advanced payment | ||

FAQ

1. When can I get the quotation?

We usually quote 24 hours after we get your inquiry. If you are very urgent to get the price, please call us or tell us in your e-mail so that we will regard your inquiry priority.

2. How can I get a sample to check your quality?

After price confirmation, you can require for samples to check our quality counter display.

If you need the samples, we will charge for the sample Express fee. But the cost can be refundable after order confirmation when your quantity of the order is more about the MOQ.

3. Can you do the design for us?

Yes. We have a professional team having rich experience in design and manufacturing. Just tell us your idea and we will help to carry out your ideas. It does not matter if you do not have someone to complete files. Send us high resolution images, your logo and text and tell us how you would like to arrange them. We will send you finished files for confirmation.

4. How long can I expect to get the samples?

After you pay the sample charge and send us confirmation files, the samples will be ready for delivery in 3-7 days. You can use your own express account or prepay us if you do not have an account.

5. What about the lead time for mass production?

Honestly, it depends on the order quantity and the season you place the order. The lead time of MOQ is about 10 to 15 days. Generally speaking, we suggest that you start inquiry two months before the date you would like to get the product at your country.

6. What is your terms of delivery?

We accept EXW, FOB, C&F and CIF, etc. You can choose the one which is the most convenient or cost effective for you.