Basic Info.

Model NO.

MK20

Raw Material

Mixing

Principle

High-Pressure Air Type

Automation

Automatic

Computerized

Computerized

Certification

CE, ISO9001:2008

Pressure Ratio

3:1

Power Source

Single Phase 220V 50Hz/60Hz

Heating Power

8kw

Driven Mode

Pneumatic

Air Source

0.8 MPa ≥0.6m³/Min

Raw Output

2~14 Kg/Min

Transport Package

Wooden Box

Specification

MK20

Trademark

MK

Origin

China

HS Code

8477800000

Production Capacity

50000PCS/Year

Packaging & Delivery

Package Size

110.00cm * 80.00cm * 110.00cm

Package Gross Weight

130.000kg

Lead Time

7 days (1 - 1 Pieces)

10 days (2 - 5 Pieces)

15 days (6 - 10 Pieces)

To be negotiated ( > 10 Pieces)

10 days (2 - 5 Pieces)

15 days (6 - 10 Pieces)

To be negotiated ( > 10 Pieces)

Product Description

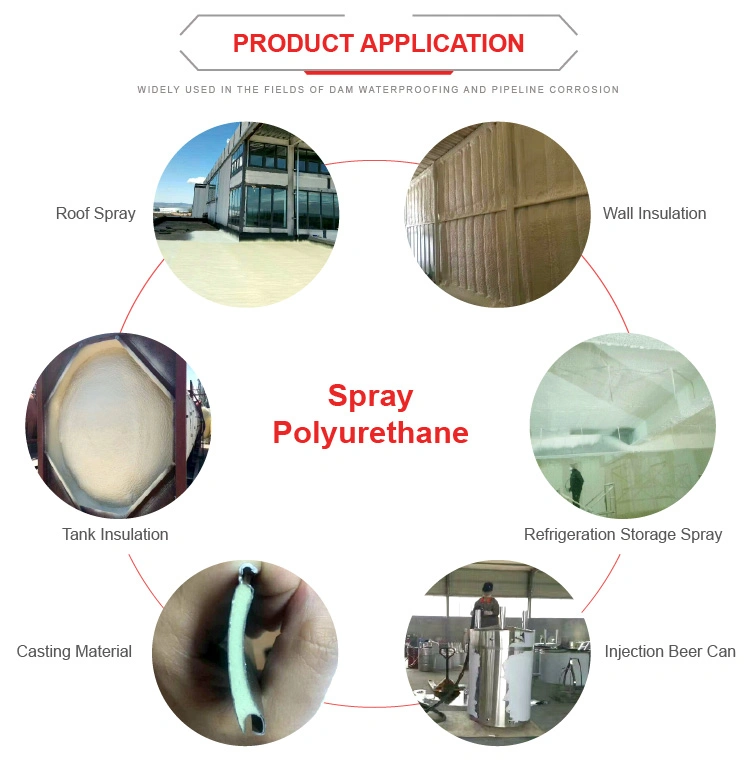

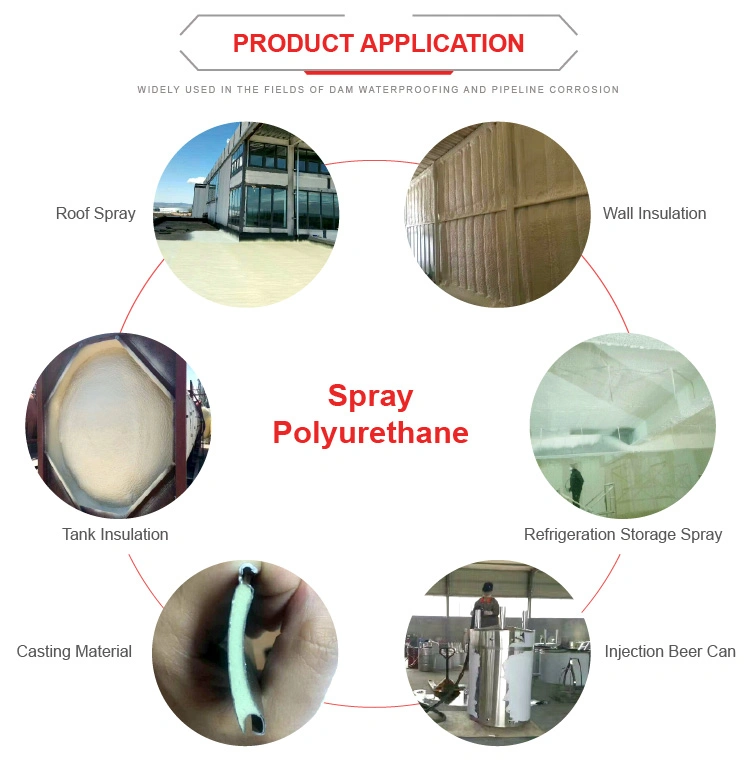

Equipment applications:

This equipment can be used for various construction environment with spraying two-component materials spray(optional) like polyurethane foaming materials, widely used in embankment waterproof, pipeline corrosion, auxiliary cofferdam,tanks, pipe coating, cement layer protection, wastewater disposal,roofing, basement waterproofing, industrial maintenance, wear-resistant linings, cold storage insulation, wall insulation and so on.

Features:

1. Stable cylinder supercharged unit, easily providing adequate working pressure;

2. Small volume, light weight, low failure rate, simple operation, easy mobility;

3. Adopting the most advanced ventilation method, guarantee equipment working stability to the maximum;

4. Minimizing spraying congestion with 4-layers-feedstock device;

5. Multi-leakage protection system to protect the safety of the operator;

6. Equipped with emergency switch system, help operator deal with emergencies rapidly;

7. Digital counting system can understand original consumption timely;

8. Reliable & powerful 380V or 220v heating system enables rapid warming of raw materials to the best state, making sure it works great in cold condition;

9. Humanized design with equipment operation panel, super easy to get the hang of it;

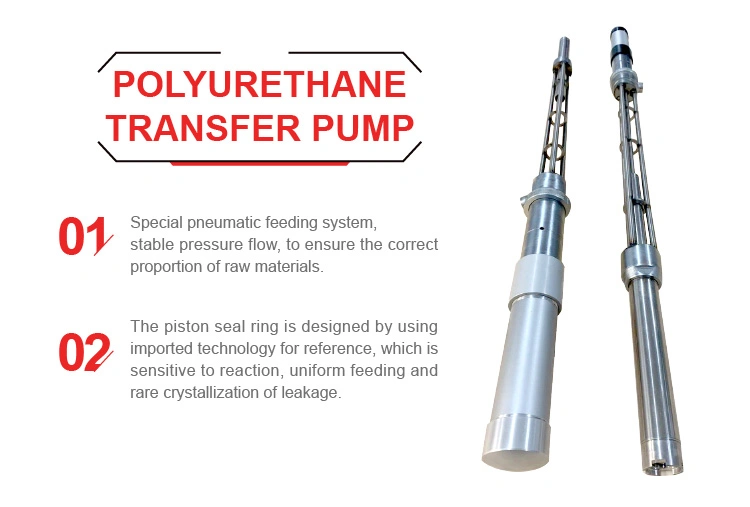

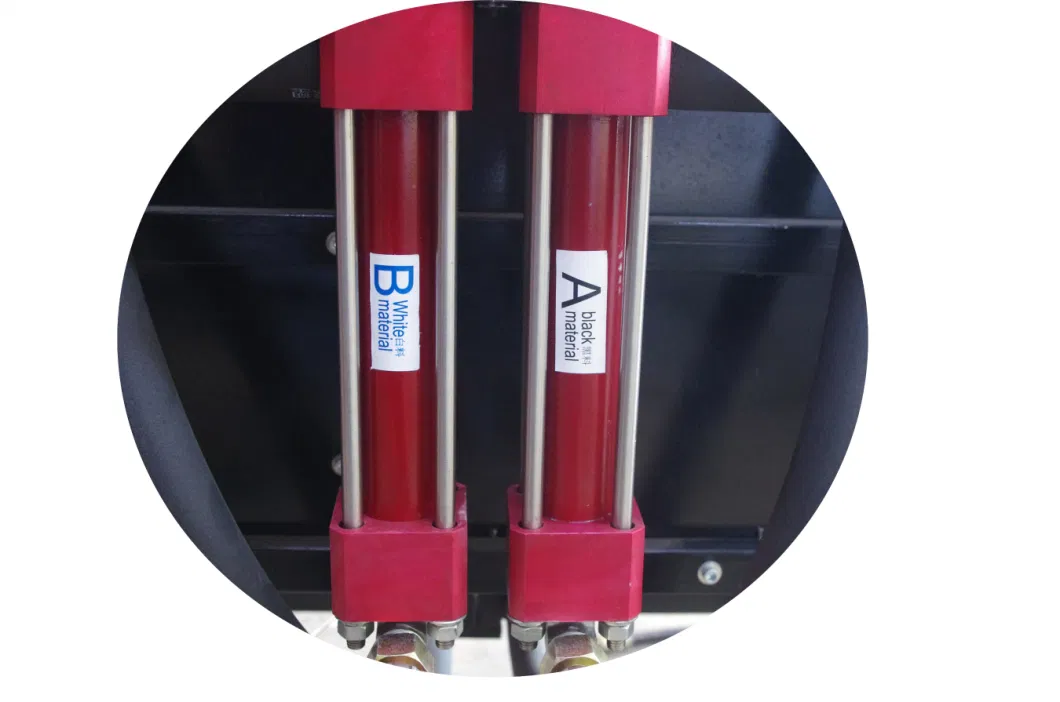

10. Feed pump adopts big change ratio method, it can easily feed raw materials high viscosity even in winter.

11. The latest spraying gun has great features like small volume, light weight, low failure rate, etc;

If you want to know more about this machine please contact Tracy

This equipment can be used for various construction environment with spraying two-component materials spray(optional) like polyurethane foaming materials, widely used in embankment waterproof, pipeline corrosion, auxiliary cofferdam,tanks, pipe coating, cement layer protection, wastewater disposal,roofing, basement waterproofing, industrial maintenance, wear-resistant linings, cold storage insulation, wall insulation and so on.

Features:

1. Stable cylinder supercharged unit, easily providing adequate working pressure;

2. Small volume, light weight, low failure rate, simple operation, easy mobility;

3. Adopting the most advanced ventilation method, guarantee equipment working stability to the maximum;

4. Minimizing spraying congestion with 4-layers-feedstock device;

5. Multi-leakage protection system to protect the safety of the operator;

6. Equipped with emergency switch system, help operator deal with emergencies rapidly;

7. Digital counting system can understand original consumption timely;

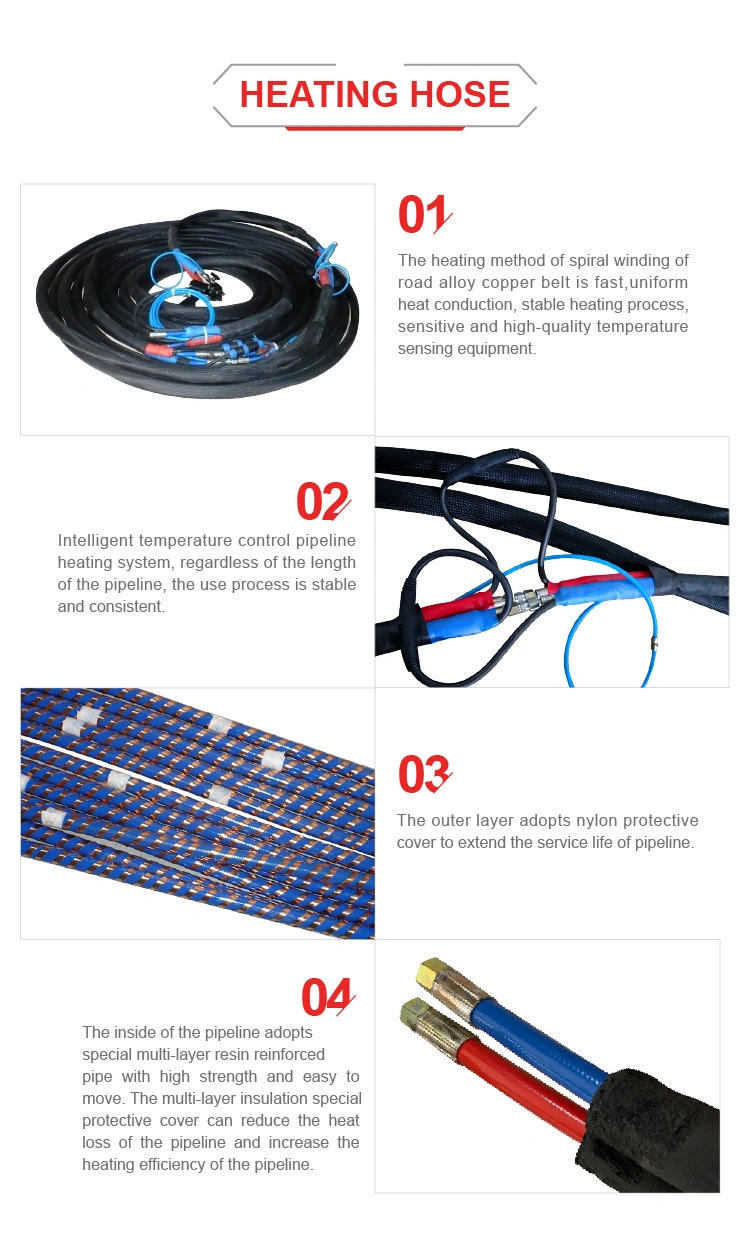

8. Reliable & powerful 380V or 220v heating system enables rapid warming of raw materials to the best state, making sure it works great in cold condition;

9. Humanized design with equipment operation panel, super easy to get the hang of it;

10. Feed pump adopts big change ratio method, it can easily feed raw materials high viscosity even in winter.

11. The latest spraying gun has great features like small volume, light weight, low failure rate, etc;

If you want to know more about this machine please contact Tracy

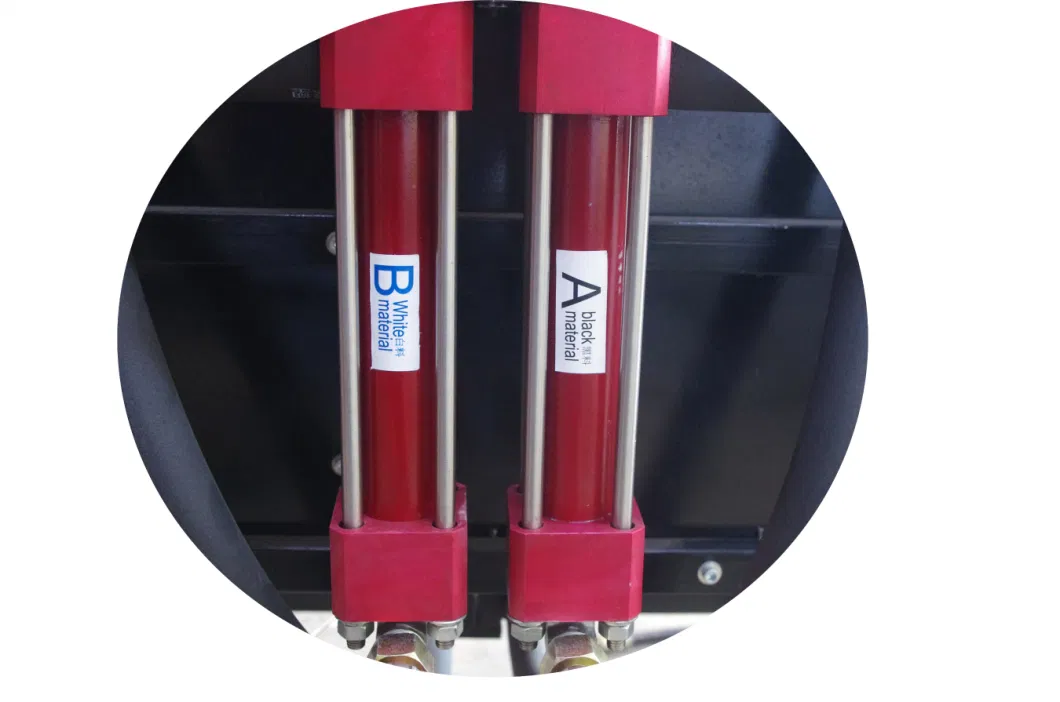

| Power source | single phase 220V 50Hz/60HZ | Heating power | 8KW Driven mode |

| Driven mode | pneumatic | Air source | 0.8 MPa ≥0.6m³/min |

| Raw output | 2~14 kg/min | Maximum output pressure | 25Mpa |

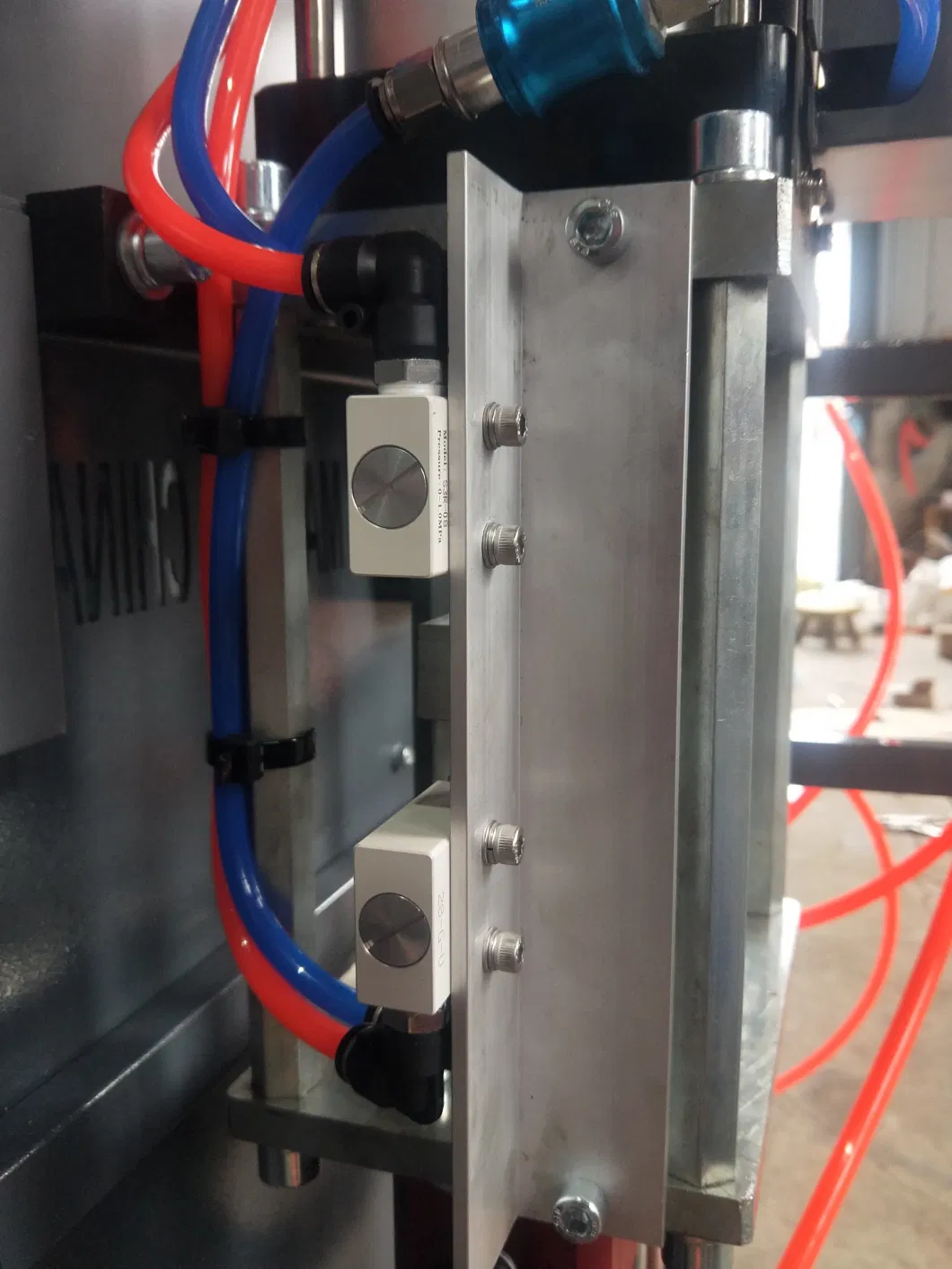

| AB material output ratio | 1:1 | Machine weight | 60KG |

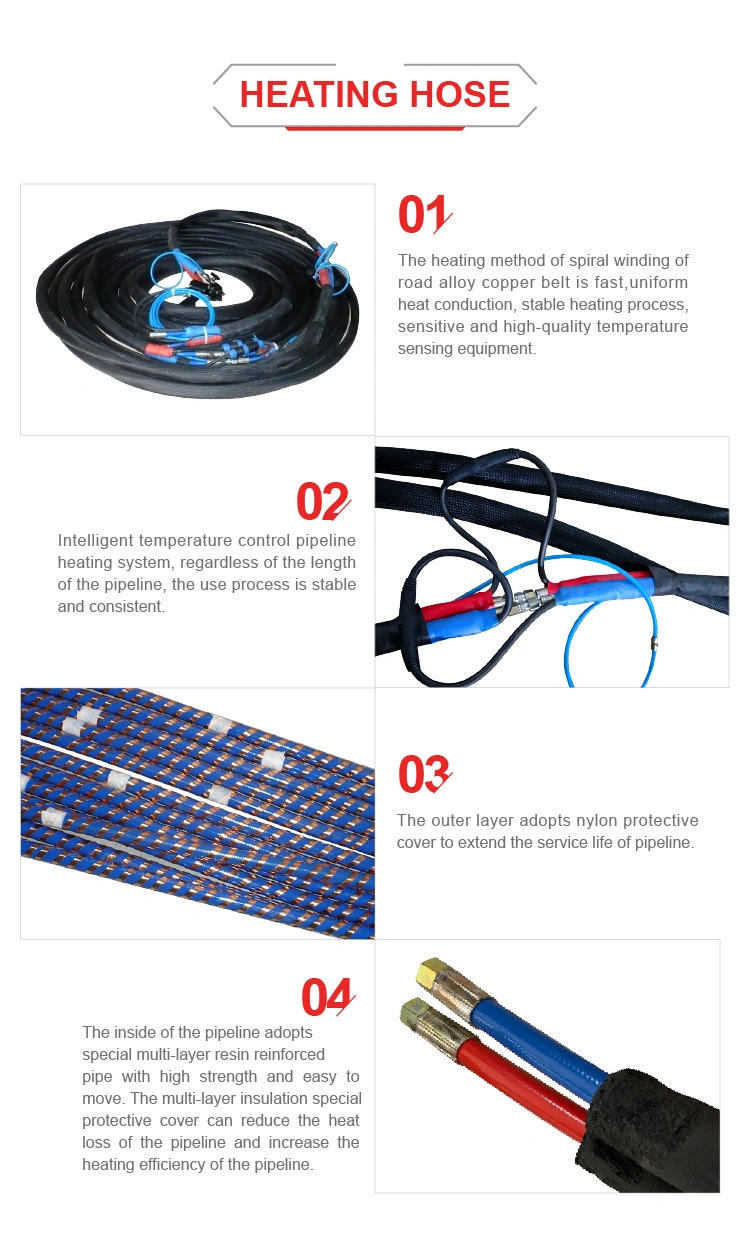

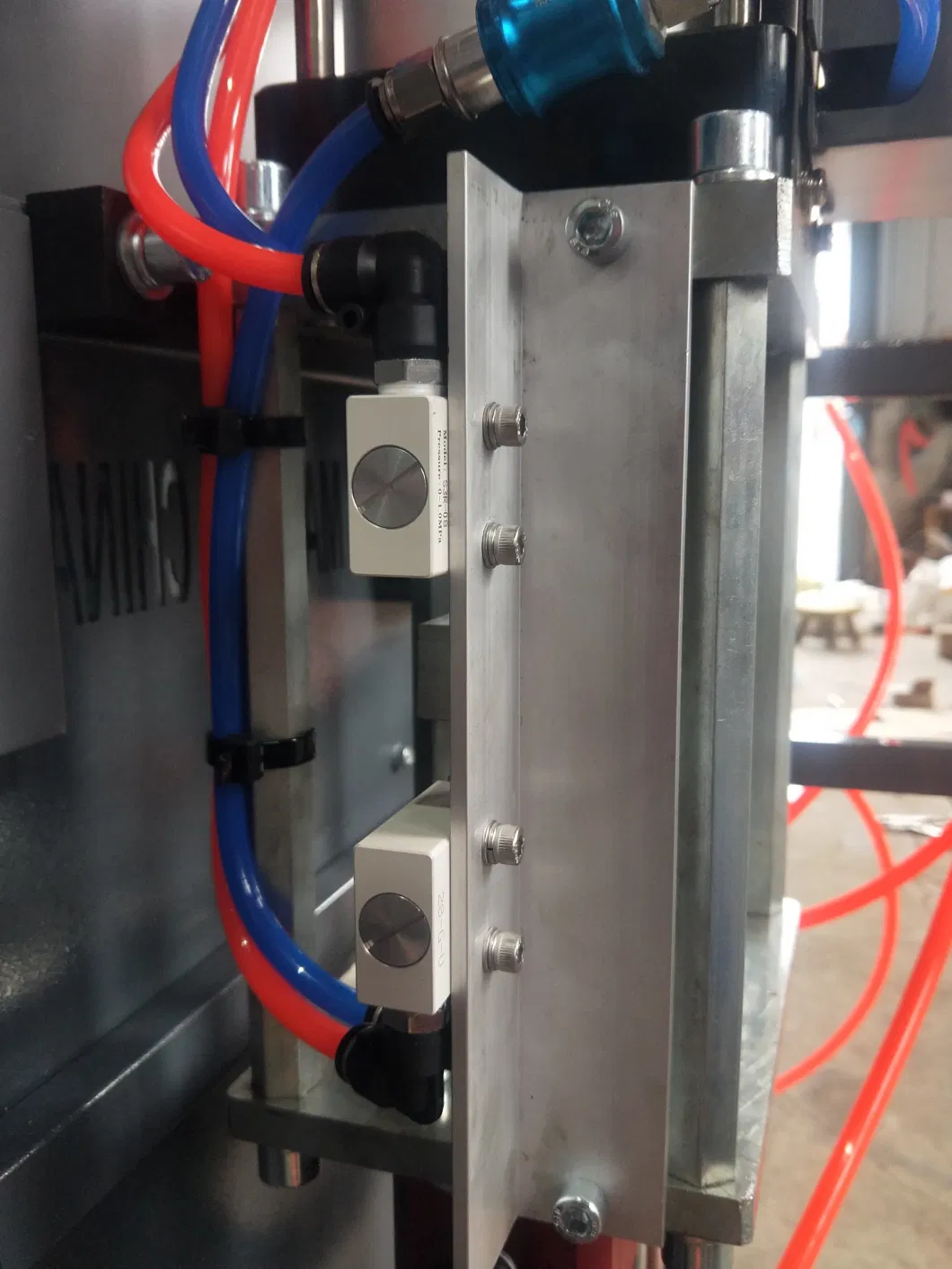

Heating mould as long as 470mm,3.6kw the longer ,the better ,it can heat the chemicals very quick ,and make it heating uniformity,so spray foaming good .The temperature error no more than 2 degree and the air cylinder never be crystal. Heating mould 470mm length ,heliciform type heating ,never to be changed.

Square type transformer 24v-72v low voltage heating ,very safe for operator ,square shape same as Glas-Craft USA brand .

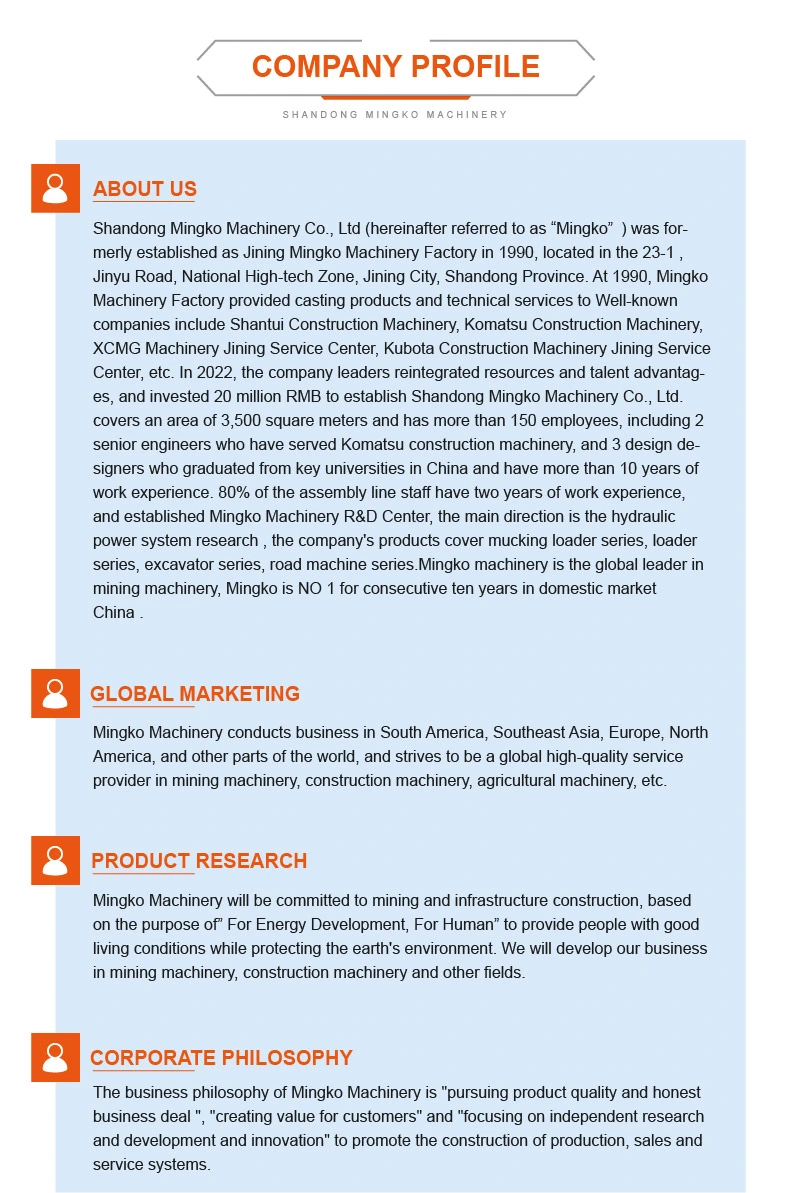

Pneumatic control switch much better than mechanical travel switch

secondary pump seal technology same as USA brand Glas-Craft .