Basic Info.

Model NO.

BQ800

Numerical Control

CNC/MNC

Processing Precision

0.003mm

Performance Classification

High-End CNC Machine Tools

Certification

CE, ISO 9001, SGS

Condition

New

Motor

Servo Motor

Display

5 Axis Digital Display

Power Supply

Anti-Electrolytic Power Supply

Z Axis Driven

Motor Driven

Operation System

Bq Operation System

Transport Package

Export Standard Wooden Packing

Specification

1700x1200x2000mm

Origin

China

HS Code

845630

Production Capacity

3000 Sets/ Year

Product Description

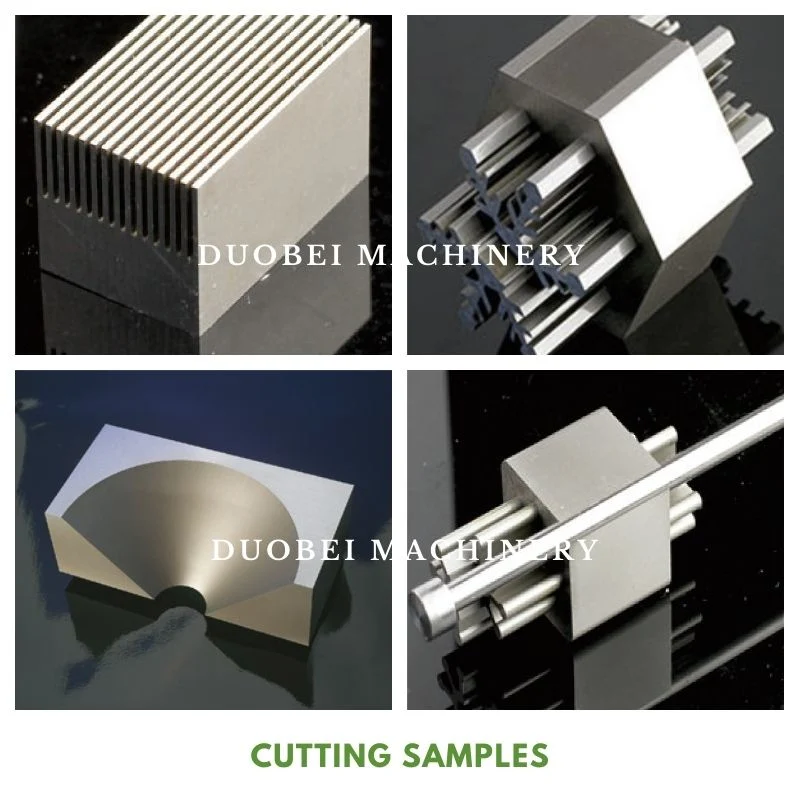

Leading CNC Wire Cut EDM Manufacturer in China, Providing customer High End EDM machines with Fast cutting speed.

Customers spread in aerospace, electronic,aotomative, 3D printing, militay and defense,mold and tooling industry.

Products export to Europe, Russia, South America, Southeast Asia, Middle East, etc

Customers spread in aerospace, electronic,aotomative, 3D printing, militay and defense,mold and tooling industry.

Products export to Europe, Russia, South America, Southeast Asia, Middle East, etc

| Parameters | BQ400 | BQ500 | BQ630 | BQ800 |

| Worktable size(mm) | 735x460 | 836x550 | 935x645 | 1120×800 |

| X/Y travel(mm) | 400x320 | 500x400 | 630x500 | 800×630 |

| Max workpiece size(mm) | 800x500 | 980x600 | 1140x730 | 1300×840 |

| Max cutting thickness(mm) | 300 | 300 | 300 | 380 |

| Max load weight(kg) | 400 | 600 | 900 | 1400 |

| U/V travel(mm) | 80x80 | 80x80 | 80x80 | 80x80 |

| Max cutting taper | ±15°/150mm | ±15°/150mm | ±15°/150mm | ±15°/150mm |

| Control type | Mitsubishi Servo , UVZ hybrid motor | Mitsubishi Servo , UVZ hybrid motor | Mitsubishi Servo , UVZ hybrid motor | Mitsubishi Servo , UVZ hybrid motor |

| Z transmission | Numerical control | Numerical control | Numerical control | Numerical control |

| Simultaneously Controlled axes | X Y U V-4 Axis | X Y U V-4 Axis | X Y U V-4 Axis | X Y U V-4 Axis |

| Wire diameter(mm) | Φ0.1-Φ0.2 | Φ0.1-Φ0.2 | Φ0.1-Φ0.2 | Φ0.1-Φ0.2 |

| Wire speed (m/s) | 1-11.4 | 1-11.4 | 1-11.4 | 1-11.4 |

| Reposition accuracy(mm) | ≤±0.003 | ≤±0.003 | ≤±0.003 | ≤±0.005 |

| Max cutting speed (mm2/min) | ≥300 | ≥300 | ≥300 | ≥300 |

| Roughness/Ra(um) | 0.7-1.4 | 0.7-1.4 | 0.7-1.4 | 0.7-1.4 |

| Water tank volume(L) | 120 | 120 | 120 | 120 |

| Filtering method | 3 layer filtration | 3 layer filtration | 3 layer filtration | 3 layer filteration |

| Power supply | Three phase 380V AC/50Hz | Three phase 380V AC/50Hz | Three phase 380V AC/50Hz | Three phase 380V AC/50Hz |

| Control system | Baqi system | Baqi system | Baqi system | Baqi system |

| Total power consumption(kw) | 1.6 | 1.7 | 1.8 | 2 |

| Max machining current(A) | 10 | 10 | 10 | 10 |

| Machine gross weight(kg) | 2100 | 2600 | 3600 | 4200 |

| Machine size(mm) | 1300x1550x1920 | 1550x1770x2050 | 1580x1820x2050 | 2090*2330*2580 |

| Top-bottom abnormity cutting | Yes | Yes | Yes | Yes |

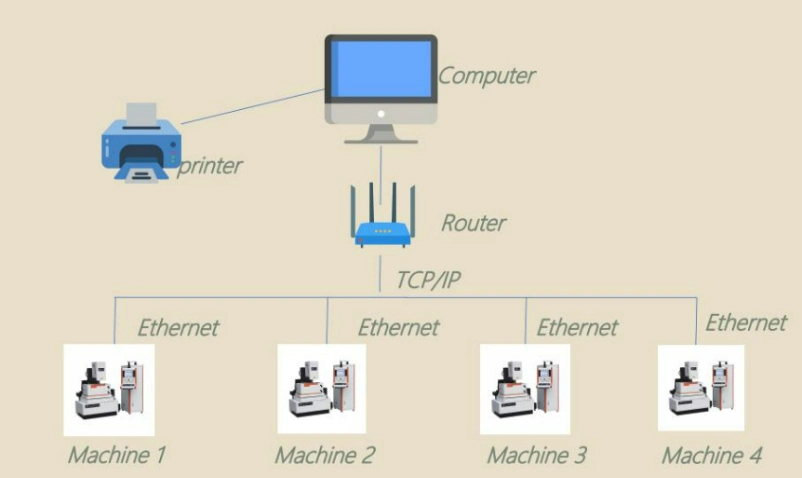

Remote control and digital management function:

Our machine integrates data management, information mornitoring and other digital functions. Users can operate monitoring software on the remote servicer in real time to monitor each machines working status, processing progress, to arrange work high efficiently.

Standard Configuration:

1) Win10 System with BQ control System(own R&D),dual CPU

2) HT300 Casting Machine Body, two times heat treatment, prevent deformation effectively.

3) 5 axis digital display and Z axis motorized freely drive up and down.

4) Pulse and anti-electrolytic power supply, to enhance cutting accuracy.

5) Automatic edge finding, automatic center finding

6) XY Mitsubishi /Panasonic servo, UVZ servo motor/ hybrid motor

7) THK / HIWIN /PMI high precision linear guide way

8) THK / HIWIN /PMI high precision ball screw

9) NSK, Japan /FAG, Germany bearings

6) XY Mitsubishi /Panasonic servo, UVZ servo motor/ hybrid motor

7) THK / HIWIN /PMI high precision linear guide way

8) THK / HIWIN /PMI high precision ball screw

9) NSK, Japan /FAG, Germany bearings

10) Japan PANASONIC converter.

11) PHILIPS Industrial Computer

12) Automatic center lubrication system.

12) Automatic center lubrication system.

System functions:

BQ series medium wire cut EDM adopts computer control, X,Y,U,V,4 axis simultaneously controlled, the discharge parameter can be automatic selected and control. It is programmed with internationally universal ISO code.The main system functions are as following:

| mirror machining | proportionally scaling |

| conventional taper cutting | top-bottom abnormality cutting |

| single-stage machining | 4 axis simultaneously cutting |

| program editing | automatic wire radius compensation |

| automatically machining condition convert | simulation check |

| return halfway | pitch compensation |

| automatic edge finding | automatic center finding |

| wire alignment | graphic real time tracking and check |

| subprogram calling | unmanned processing(power-off after finishing) |

| back to the origin point and suspension point | wire feeding speed adjustment |

Full travel reposition accuracy ≤ ±0.003mm

Measured by Laser Interfermeter.

- Reverse error : 0.0009mm

- System deviation: 0.0016mm

- Average deviation: 0.0015mm

- Accuracy: 0.0016mm

- Repeatability: 0.0009mm

- R+(single repeatability): 0.000mm

- R-(single repeatability): 0.000mm

- A+(single accuracy): 0.0016mm

- A-(single accuracy): 0.0014mm

Delivery 3000 sets a year:

Contact us for more details, you will get reply within 24 hours .