- Overview

- Company Profile

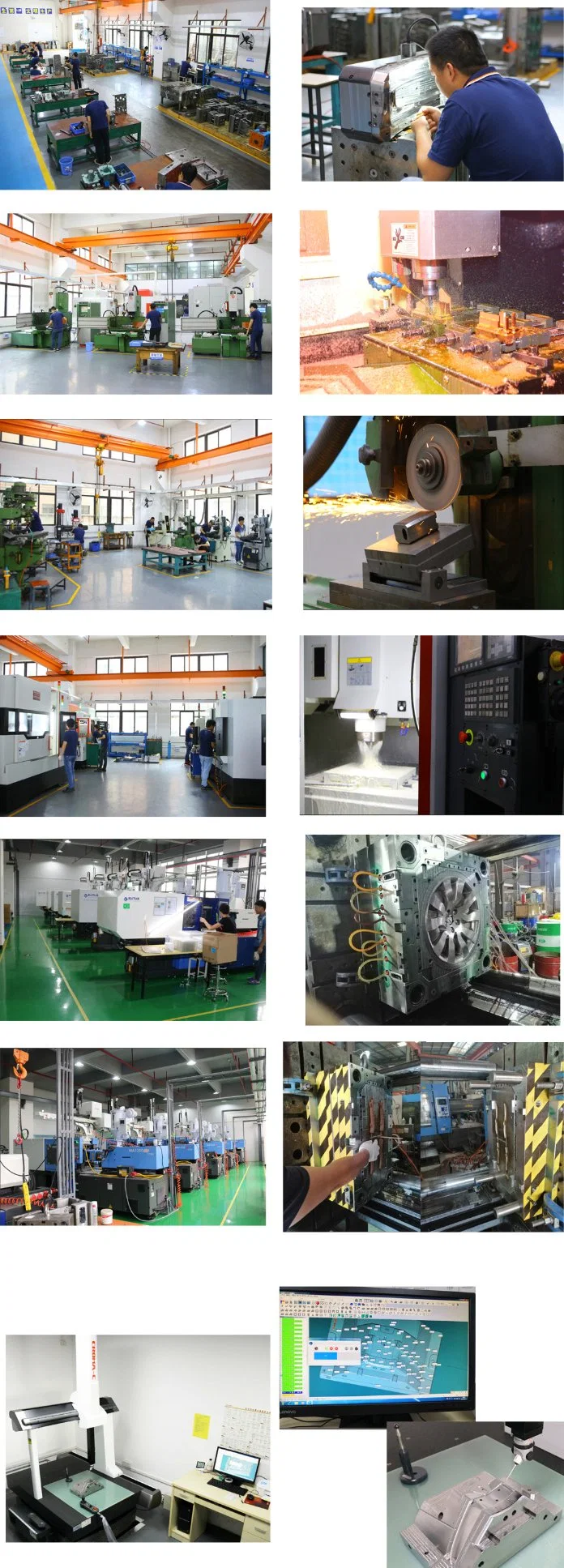

- Work Shop

- Packaging & Shipping

Basic Info.

Product Description

Howe is an OEM/ODM factory, customized your products to meet your needs is our advantage. We are managed by a group of professionals with many years of experience in mold design, molding technology and Quality control.

Product Description

| Mould type | Plastic injection mould |

| Mould material | 45#, 50#, P20, 738, 738H, 718, 718H, NAK80, 2316, 2316A, S136 etc |

| Product material | ABS,PA6,PA66,PP,PC,TPU,POM,PBT,PVC,TPE,TPV,TPO,TPR,EVA,LDPE etc. |

| Runner system | Cold runner or hot runner |

| Mould precision | ±0.01mm. |

| Mould machine center | Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes etc. |

| Mould Base type | LKM, FUTA, HASCO, DME, TSMP, Or as per customer's requirement. |

| Steel hardness | 20-60HRC |

| R&D | 1. Drawing design and making for products and mold; 2. Mold drawing revising; 3. Production time and quality control in each machining process. |

| Mould lifetime | Commonly used: 1. 300,000-500,000 shots for 1 year under normal use procedure for pre-hardness steel material. 2. 500,000 shots for 1 year under normal use procedure for heat treatment steel material. |

| Port | SHEN ZHEN |

| Manufacture type | Injection mold, surface treatment available |

| Delivery | By DHL/FedEx/UPS/TNT, or by sea, depends on your time. |

| Supply ability | 30 sets per month |

•Injection molding parts for model shops, toys

•Injection plastic parts for new product design & development

•Custom plastic parts for construction

•Plastic injection for Information Technology

•Molded plastic parts for payment system

•Precision plastic parts for Agricultural equipment

•Injection plastic parts for others like cosmetic case

•Plastic injection molding parts for architectural parts

•Plastic injection molded auto components

•Injection-molded household utility products

•Plastic molded electronic enclosures

Howe Mold was founded in 2010 to produce top class injection molds for the plastics industry. This company has an extensive background in building tools for the electronics, medical, computer, agricultural, automotive, and communications industries. Our customers turn to us to design and build various types of steel and aluminum, single or multi-cavity, molds for injection, structural foam, rim, blow, gas assist and structural web processes. We also design and build aluminum injection molds for limited production runs.Today we serve customers in the computer, automotive, medical, material handling, electronics, and pet industries.

Specializing in three main areas:

1. Manufacture of custom prototype and production injection molds from your part data to a complete mold in just weeks.

2. Rapid turnaround mold repairs, which allow you to get your tools back into production quickly.

3. High quality machining, grinding, CNC machining, EDM and CNC EDM.

1> Usually, your goods will be packaged in plastic bags, anti-shock foam, cartons, waterproof and environmental adhesive tape. For other individual demand in packaging, please specify in communication.

2> Unless specially asked for:

we choose DHL, Fedex for small package; ( 3-7 days )

UPS, TNT and Air Lift for big package. ( 7-11 days )

Personal offical express account and forwarder are all good.

For cheap shipping way and within 2kg, E-Post ( 7 days ) and China Post Air Mail ( 30 days) are available.

3> Usually non-custom process goods can be delivered in 3-5 days; custom process goods can be delivered in 7-30 days. Please consult for professional advise.