Basic Info.

Model NO.

HR-RS1600

Computerized

Computerized

Max Cutting Width

1500mm

Max Cutting Length

2000mm

Bag Cutting Speed

60 PCS/Min

Bag Cutting Thickness

0.05-0.5mm

Total Power

5kw

Machine Weight

2500kgs

Transport Package

as Required

Specification

8000*2100*1500mm

Trademark

HuaRui

Origin

China

HS Code

84778000

Production Capacity

15set/Month

Product Description

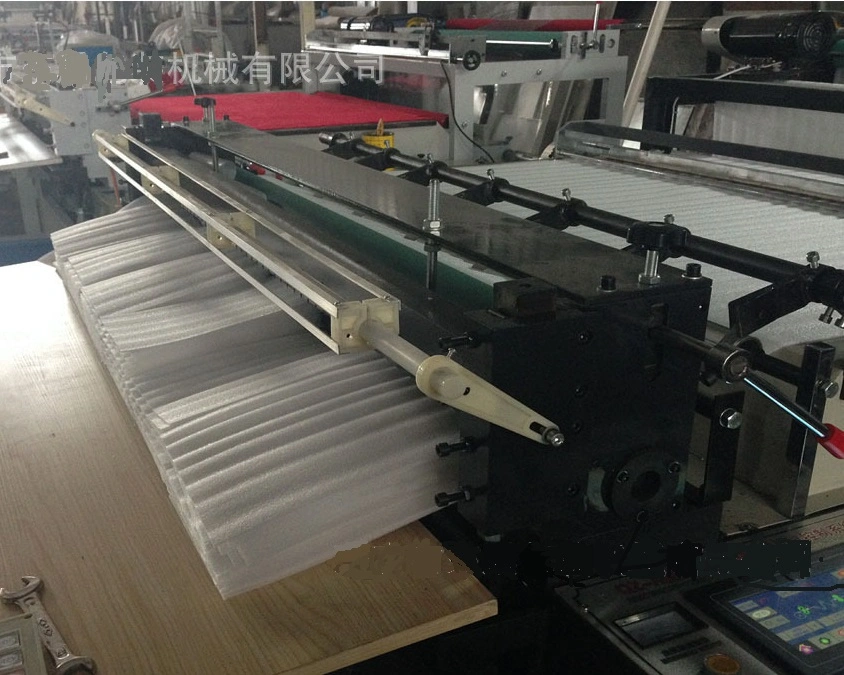

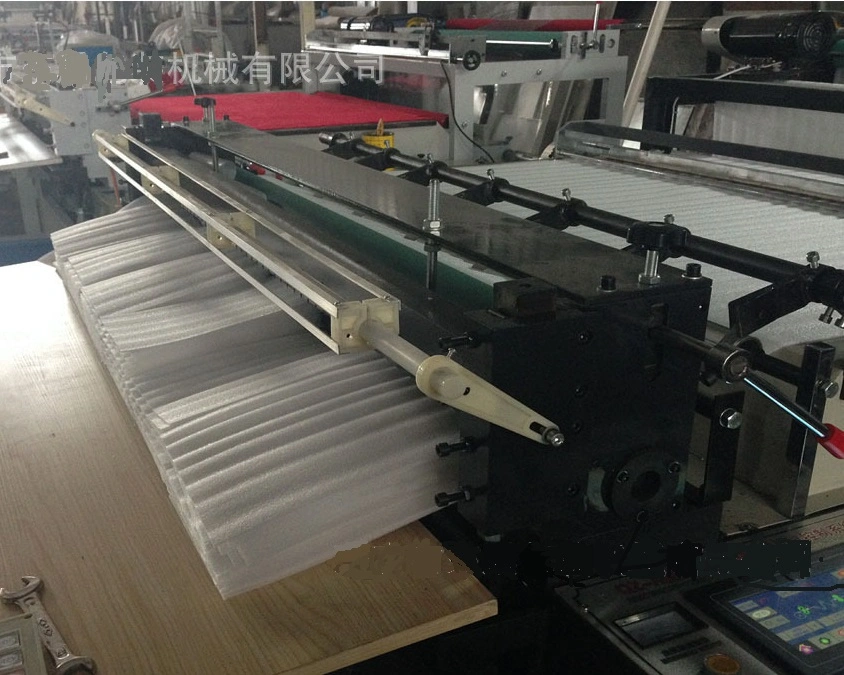

1500mm EPE Foam /Laminated Aluminum Foil Film Roll to Sheets Computer Cross Slitting Cutting Machine price

1. Usage:

This machine is suitable for cutting of roll materials such as pearl cotton, no-woven fabric, gold and silver cardboard, A4 paper, plain rainbow paper, positioning laser transfer paper, white board paper, plastic sheet, etc.

The electrical main control system adopts computer step control or (servo system control), man-machine interface operation and dynamic display; The fixed length control is controlled by the stepping motor system, and the automatic marking photoelectric switch ensures the cutting accuracy. The control mode of the whole machine is advanced. The speed of the host, servo motor and feeding motor is controlled by the computer to achieve synchronous operation. It has the advantages of high cutting accuracy, fast speed, convenient feeding and neat stacking.

2. Characteristic:

Compact structure, high degree of automation, with computer control, variable frequency speed regulation, automatic counting, audible and visual alarm, photoelectric tracking and other functions. It is applicable to the horizontal cutting of roll materials after printing and lamination, and is a necessary equipment for roll printing composite materials to cut into sheets.

3. Main parameters:

4. Configuration:

Our Exhibition:

Packing and Delivery:

Our workshop:

If you are interested in this machine, welcome to contact us.

1. Usage:

This machine is suitable for cutting of roll materials such as pearl cotton, no-woven fabric, gold and silver cardboard, A4 paper, plain rainbow paper, positioning laser transfer paper, white board paper, plastic sheet, etc.

The electrical main control system adopts computer step control or (servo system control), man-machine interface operation and dynamic display; The fixed length control is controlled by the stepping motor system, and the automatic marking photoelectric switch ensures the cutting accuracy. The control mode of the whole machine is advanced. The speed of the host, servo motor and feeding motor is controlled by the computer to achieve synchronous operation. It has the advantages of high cutting accuracy, fast speed, convenient feeding and neat stacking.

2. Characteristic:

Compact structure, high degree of automation, with computer control, variable frequency speed regulation, automatic counting, audible and visual alarm, photoelectric tracking and other functions. It is applicable to the horizontal cutting of roll materials after printing and lamination, and is a necessary equipment for roll printing composite materials to cut into sheets.

| Model | HR-RS1600 |

| Max cutting width | 1500mm |

| Max cutting length | 2000mm |

| Maximum unwinding diameter | ¢1100mm |

| Max cutting width | 60m/min |

| Cutting precision | ±0.5mm |

| Power | 5KW |

| Machine weight | 2500kg |

| Machine size | 8000×2100×1500mm |

4. Configuration:

| NO | Name | Qty | Origin | Remarks |

| 1 | Computer screen | 1pc | zhongxin | Touch screen |

| 2 | Frequency converter | 2set | Bester | 2.2KW and 1.5KW |

| 3 | Main motor | 1set | Shanghai | Dedong(2.2KW) |

| 5 | Important structure of the machine | 1set | Channel steel structure, cast iron | Ruian local |

| 6 | Cutter | 1set | anhui | Wuxing brand, L:1650MM |

| 7 | Electric appliance | 1set | Shinaide | |

| 8 | electrostatic | 1set | Hongwei | Hongwei |

| 9 | Magnetic powder 5 kg | 4set | Shengda | Ruian local |

| 10 | Aluminium roll | 1set | 70MM | Zhejiang Jiangnan Aluminum |

| 11 | Rubber roller | 100MM | Factory | |

| 12 | Feeding motor | 2set | servo motor | Zhongxin 4.2KW |

| 13 | Automatic feeding simulation lighting control | Factory | No need adjust | |

| 14 | Manual feeding | Dia 1100mm | ||

| 15 | Automatic stacking and conveying function | 1set | Factory | Lifting height 40cm |

| 16 | Vertical Cutting knifes | 1set | 5pcs | |

| 17 | Lift motor | 1set | Including deceleration motors and synchronous motors | Together run |

More machine photos:

Our Exhibition:

Packing and Delivery:

Our workshop:

If you are interested in this machine, welcome to contact us.